Theme

Digital Transformation

Green Transformation

MENG YI INDUSTRIAL CO., LTD.

Product Description :

The dimension of Drill with Inner-outer Chamfer Tool is from Ø3.0 to Ø25.0. Drilling and chamfering are process on the machine once. The material of drill is tungsten carbide and it could be customized. Replaceable insert could be sharpened.

Video: https://youtu.be/kTbYR3u_lfo

TAI WAN C&U INTERNATIONAL TRADE CO.,LTD.

Product Description :

軸承製造業是人本集團的主導產業,其生產的精密低噪音軸承是經國家軸承監督檢驗中心檢測,精度儲備率100%,優等品率100%,Z3組穩定達產率95%,Z4組穩定達率60%以上,在國內同行業處於領先地位,填補了國內空白。人本(C&U)軸承還多次獲中國“精品軸承”稱號。現已形成溫州、杭州、無錫、上海、南充、蕪湖和黃石等七大軸承生產基地,已擁有73家軸承成品和配件製造企業,下屬成員企業146家。集團能生產內徑1.0mm至4000mm範圍內的軸承三萬餘種,在國內同行業中產銷排名第一。

CAPTAIN SCIENCE CORPORATION

Product Description :

For the air cleaning we offer many different models of mist collectors: centrifugal (in the versions turbine, single centrifuge and double centrifuge), static filters and specific units for very high throughputs or centralized systems. All the models are ready for being arranged with a range width of modules of pre and after-filtration therefore to resolve in specific way any type of problem. Our mist collectors can be directly installed on the machine tools. They remove the polluting from the source, and can easy be moved, and used again on other machines or switched off in case they are not used.

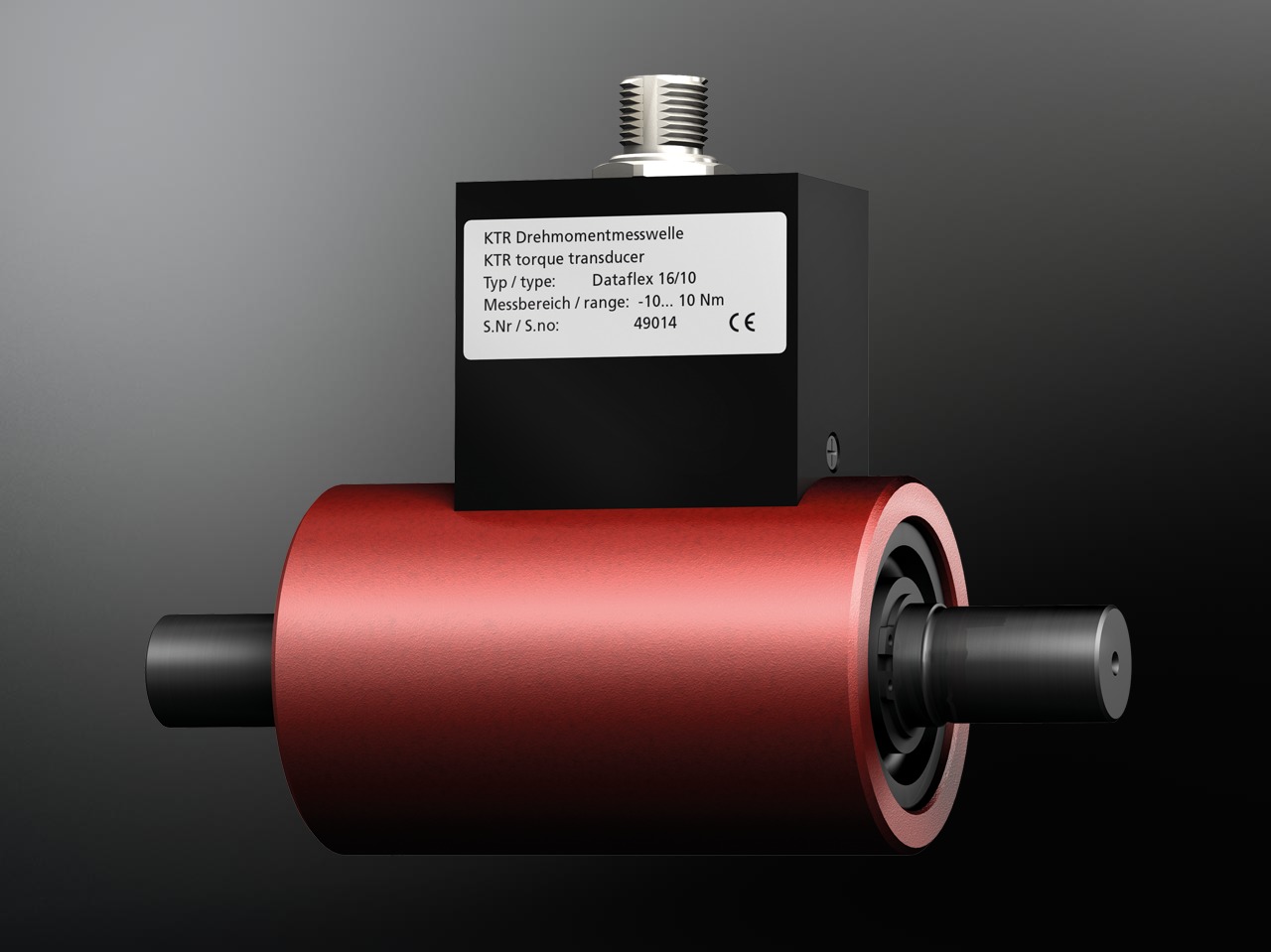

KTR TAIWAN LTD.

Product Description :

The recently developed DATAFLEX® 16 is available for measuring torque ranges of 10 Nm, 30 Nm and 50 Nm. The torque is measured using the well-approved technology of wire strain gauges combined with the latest electronic components.

The torque signals are processed without contact at a high resolution of 24 bit achieving an accuracy of 0.1 % of the terminal value. Supplementary to torque measuring the size 16 has a speed encoder providing two signals with a resolution of 360 pulses per revolution.

FINTEK INDUSTRY COMPANY LIMITED

Product Description :

Heavy-duty Hydraulic Shearing (Guillotine) Machine

Streamline and solid body frame designed, safety-oriented thinking

maximum cutting capacity in 6.5mm/ 3100mm mild steel

Build in high quality/stability hydraulic system with flexible touch screen and friendly NC operating interface auxiliary.

Absolutely is your best partner and indispensable production equipment in your factory

HO CHEN MACHINERY & ELECTRIC IND. CO., LTD.

Product Description :

X axis travel:

Single movement: 1125 mm (44" )inch

Dual movement: 560 mm (22") inch

YZ axis travel 700x500 mm (28"x20") inch

Work table: 1850x850 mm (73"x33") inch

Max. Workpiece: 2800x1400x700 mm (110"x55"x28") inch

Max. Workpiece weight: 5800 kg

Max. electrode weight: 400 kg

Machine net weight:8350 kg

Oil level: 110-550 mm (4"-22") inch

Packing size(LxWxH): 5430x4600x3090 mm (214"x181"x122") inch

Work Table to platen: 700-1200 mm (28"-47") inch

Filter: 4

Paper filter:8

Capacity:3400 Liters

Machine Features

> Windows CE controller

> A dialog window with picture description.

> Special repaired frames to quicken the maintenance speed.

> Close-loop design of digital feedback on three axes of the machine significantly increases positioning precision and ORBIT-CUT machining accuracy and efficiency.

> Simple operation interface.

> Common function keys are located on the operational panel for direct use.

> Hot key setting.

> ATC (automatic tool change) and C-axis 360° index can be installed; the process of coarse machining to ultra-fine machining can be completed at one time.

> Dialogue diagram provides various hole-expanding modes such as quick search of edge, centers and datum marks.

> Rich color graphic (the same resolution as a PC screen).

> Automatic multi-step machining (coarse, medium coarse, medium fine, fine, superfine)—up to 10 steps.

> Unlimited number of machining conditions can be saved as machining archives. Each set of machining conditions can be edited, modified or stored. They are easy to edit and easy to find.

> Automatic origin search and multi-point coordinate memory capability.

> 1/2 design capability, ARC automatic discharge waveform detection and automatic adjustment.

> Automatic center position detection, automatic compensation, search of hole center and deepest point; fixed hole machining (cyclic mode, independent mode), which is suitable for different machining conditions; Radial, circular, square, linear (vector), coning, 45° hole-expanding machining.

> Three-axis beeline, two-axis arc, three-axis helix.

> Chinese/English versions interface, metric/British system switch and Z-axis quick up, quick down, slow up and slow down capability.

> Lateral machining, three axes, six directions (plane rotation).

> All alarms describe the source, date and exact time of problem occurrence.

> Optical scale is applied for close-loop position control, enabling extreme position for machining.

> Automatic editing—settings can be done according to type of material, work piece size, machining depth, one side die clearance, final current and rate of electrode wear.

> CNC models possess conventional capability of consistent level of energy discharge, achieving stable and rapid machining and smooth high quality on machining surface while the rate of electrode wear is still low.

> Monitor page indicates machining path and orbital pattern in use.

PRAISE PRECISION IND. CO., LTD.

Product Description :

NEW PRODUCT- CUTTING KNURLING TOOLS USED ON LATHE

Method of forming knurling

1. Press forming(Form knurling)

Press knurling tool directly to workpiece in turning on the lathe

to form the patterns. Pressure is applied to the lathe spindle, and the outside diameter of workpiece will become bigger

2. Cutting forming(Cut knurling)

The knurling tool is applied to workpiece just like cutting, less pressure

to lathe spindle and less machining resistance, forming a clear patterns, the best choice for using on CNC lathes

FOCUS CNC CO., LTD.

Product Description :

30-degree slant bed provides high-stiffness capacity, long-term stability and excellent chip removal capability. Compact design makes the machine length shorter and the floor space smaller. To efficiently utilize the floor space, the chips can be discharged from the side or rear of the machine. To clean the coolant tank from the front of machine to make the plant layout easier. Auto load/unload system provides graphic user interface, quick setup for different work-piece, customized program and work-piece counter. Efficient loading/unloading and quick work-piece swap makes better performance.

DKSH Taiwan Ltd.

Product Description :

The PC R series evaporators have a heating system based on a heat pump and operate under vacuum at 5kPa and around 30°C (86°F).

Heat exchange occurs within a conical jacket, and the boiling chamber inside part is cleaned by internal scrapers that continuously stir concentrate. This configuration is designed to produce a concentrate with a high final concentration and a distillate with low conductivity.

•From 0,1 to 2 m3/day – 0.02 to 0.37 US gpm of distillate

•Dramatic reduction of volumes and disposal costs

•Matter recovery

Extremely suitable when:

•the wastewater has a high initial content of dissolved or suspended solids

•the wastewater is already pre-concentrated

•the daily volumes are relatively small

•the distillate has to be of the highest quality

•the concentrate has to be recycled

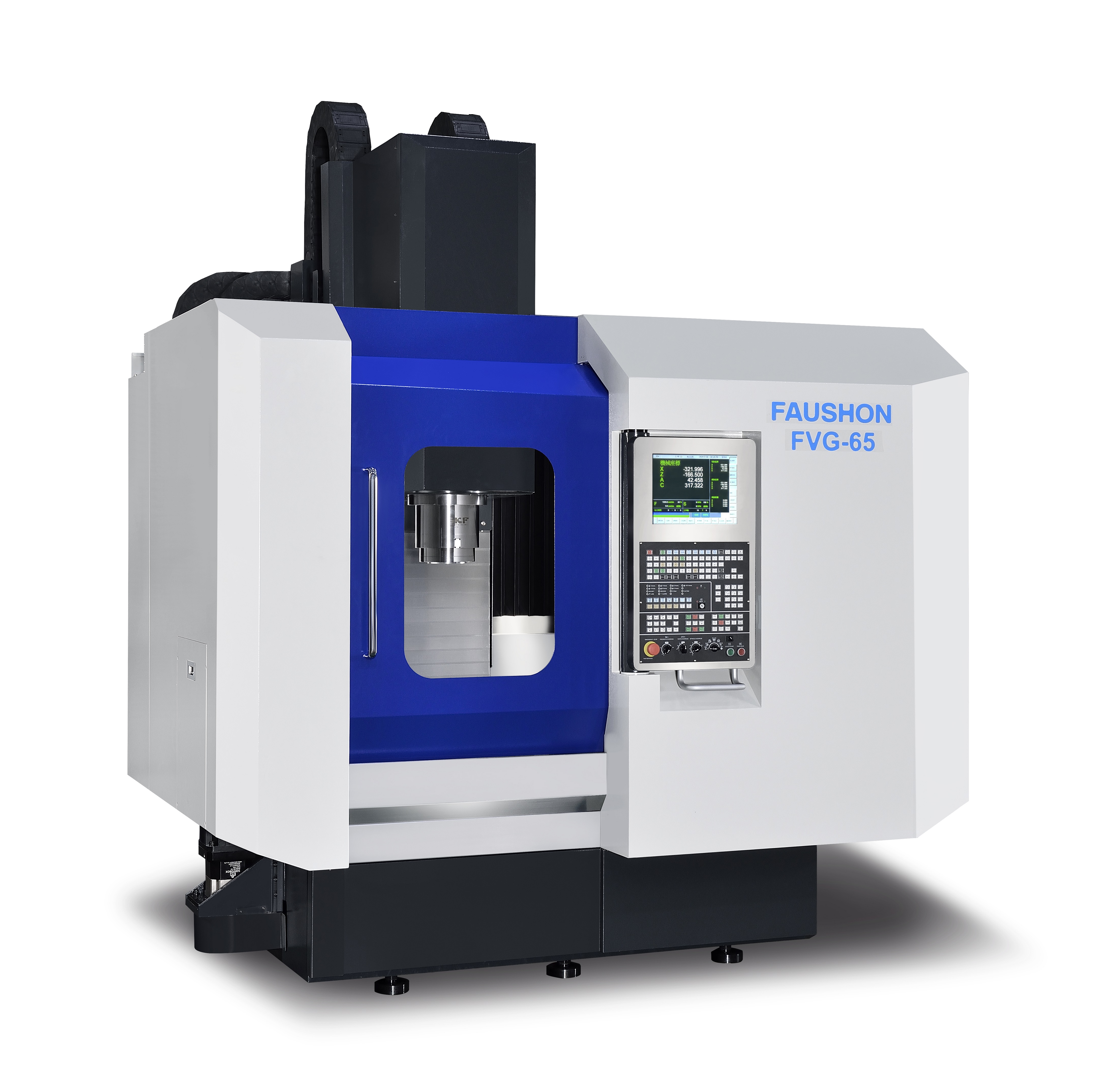

Fulson Industrial Co., Ltd

Product Description :

This model is the culmination of years of careful research and development by Faushon. It boasts a sturdy exterior and robust structure, with all operating handles and active control panels designed to be within the operator's optimal range and most comfortable operating position. This design adheres to ergonomic principles, providing you with higher work efficiency.

With our extensive experience in professional grinder manufacturing, we never compromise on accuracy. We can assure you that our machines offer high precision and reliability. We provide a variety of options and solutions to help address on-site challenges. Our machines are capable of multitasking and offer a high cost-performance ratio in terms of accuracy. The main structure design of the machine undergoes thorough finite element analysis and rigorous review of key components to achieve high precision and reliability.