Theme

Digital Transformation

Green Transformation

A Being Kou Tools Co., Ltd.

Product Description :

After becoming frustrated by the existing coolant hose products on the market; all of which suffered from a variety of shortcomings, Arnold Lockwood conceived the idea for the modular hose that became Loc-Line®. The shortcomings of the existing products included, metal coolant hoses that would not stay where they were positioned and plastic hoses with metal positioning rods that broke.

In 1981 Lockwood Products was formed to develop and distribute Loc-Line®. The first products were shipped in August of 1983.

Loc-Line® quickly became the standard for coolant delivery around the world and was easily recognized by our Blue and Orange colors and consistent high quality.

Today Loc-Line® is still the leader in modular hose and continues to innovate in the modular hose field. Loc-Line® is used not only as a coolant hose but for air delivery, smoke and dust removal vacuum systems, agriculture, third arm uses including positioning cameras, lights and items for handicap assist.

We here at Lockwood Products, Inc are proud to have originated the modular hose Loc-Line© that remains the standard for the industry worldwide!

Please visit one of our distributors today and see for yourself why Loc-Line remains the best and most versatile solution in the world today!

FUTECH PRECISION CO.,LTD.

Product Description :

Ultra-short, high speed, light weight.

Designed with a detection device, which can be equipped with an inductive proximity switch.

Easy to adjust to ensure the correct operation of the hydraulic cylinder.

Built-in safty self-locking valve and pressure relief valve.

Dual-purpose type, can be installed by the front and rear ends.

The oil pipe must be connected to the oil pressure tank separately to avoid back pressure.

DAH LIH MACHINERY INDUSTRY CO., LTD.

Product Description :

龍門型結構,高速加工極穩定。<br />

12,000 / 15,000 rpm高速直結式主軸。<br />

X, Y, Z軸全配置滾柱型線軌。<br />

X, Y, Z軸快速進給率30米/分。<br />

獨創主軸熱補償功能。<br />

立柱結構左右對稱,為最佳熱平衡設計。<br />

X軸獨立於床台上,Y軸獨立於立柱上,無重疊之負荷。<br />

工作台全行程支撐無懸垂,偏移問題,確保最佳加工精度。<br />

三軸滑軌配置線性滑軌,形成穩定順暢,並兼顧高速加工之需求。<br />

衝錘式主軸頭、開頂式護罩。<br />

滾珠螺桿中空冷卻。

LEADWELL CNC MACHINES MFG., CORP.

Product Description :

Twin spindle & twin turret design, it can turn the different parts on the spindle and identical parts on both spindles at the same time. Integrated with 3-axis robot arms, to reach different OP and automation requested. Considering the turning efficiency, with automation high-speed robot reduces the loading/unloading time, with a high rigidity stricture design to increase the stability. On the other hand, the multiple types of robot arms will be able to satisfy the different demands of the client.

Max. swing: 290mm

Max. turning diameter: 290mm

Max. turning length: 220mm

X-axis travel: 195+5mm

Z-axis travel: 300mm

Spindle speed: 3500rpm

Spindle nose: A2-6

Chuck size: 10"

Spindle motor power: 11/15kw

Number of tool stations: 12T

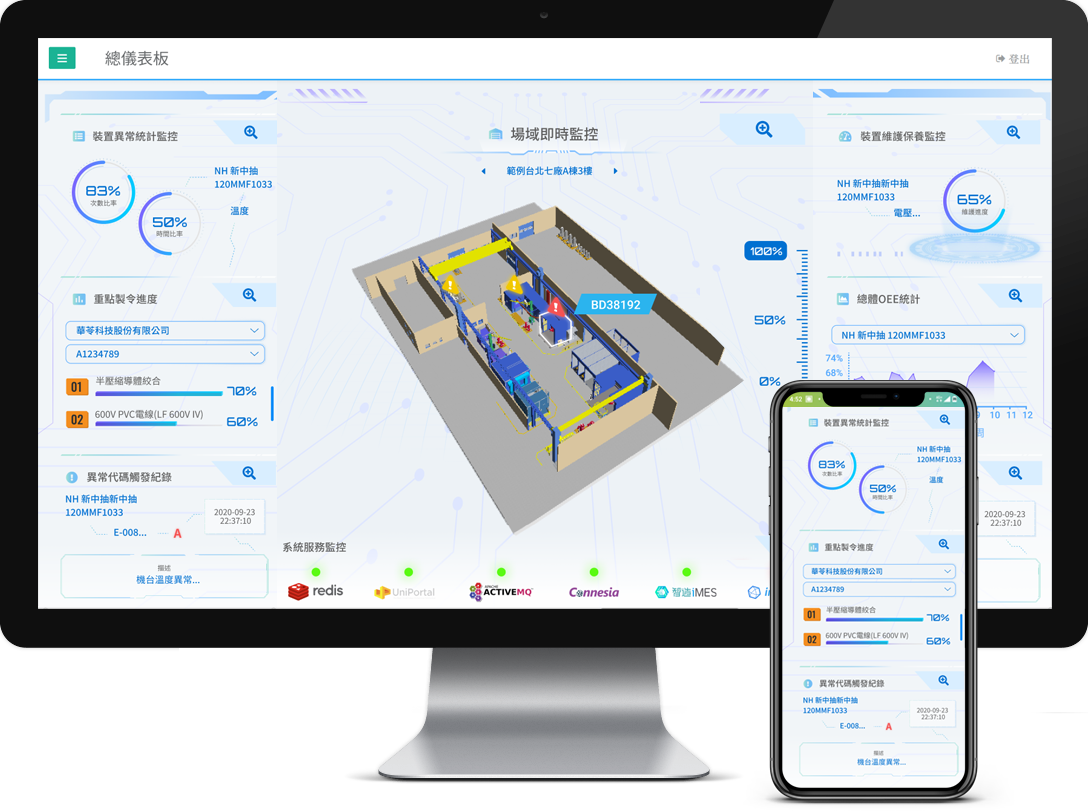

Administration for Digital Industries, moda

Product Description :

iMES's real-time Internet of Things and monitoring reports gradually achieve smart manufacturing remote monitoring, providing each manufacturing customer with six major capabilities, including real-time collection of production data, working hours management, exception notification, intelligent management of production lines, optimization of production schedules, etc. Intelligent production applications realize automated and efficient interconnected factories.

1. Arrange optimal production schedule.

2. Generate ERP work orders.

3. Automatically manage machine recipe parameters.

4. Two-way real-time control of the machine device.

5. Manage the triggering rules for subsequent tasks on the machine.

6. Automation machine completion report information.