Theme

Digital Transformation

Green Transformation

HO CHEN MACHINERY & ELECTRIC IND. CO., LTD.

Product Description :

X axis travel:

Single movement: 2550 mm (100") inch

Dual movement: 1275 mm (50") inch

YZ axes travel: 850x600 mm (33"x24") inch

※Y axis can be increased to 1300 mm(51") (Option)

※Z axis can be increased to 1000 mm(39") (Option)

Work table: 3100x1600 mm (122"x63") inch

Max. Workpiece: 4100x2050x1250 mm (161"x81"x49") inch

Max. Workpiece weight: 22000 kg

Max. electrode weight: 500 kg

Machine net weight: 29410 kg

Oil level: 110-1000mm (4"-39") inch

Occupy size(LxWxH): 6480x6600x4600 mm (255"x260"x181") inch

Work Table to platen:

600mm Z travel machine: 1138-1738mm (45"-68")

1000mm Z travel machine: 740-1740mm (29"-69")

Filter: 4

Paper filter:8

Capacity:11300 Liters

Machine Features

> Windows CE controller

> A dialog window with picture description.

> Special repaired frames to quicken the maintenance speed.

> Close-loop design of digital feedback on three axes of the machine significantly increases positioning precision and ORBIT-CUT machining accuracy and efficiency.

> Simple operation interface.

> Common function keys are located on the operational panel for direct use.

> Hot key setting.

> ATC (automatic tool change) and C-axis 360° index can be installed; the process of coarse machining to ultra-fine machining can be completed at one time.

> Dialogue diagram provides various hole-expanding modes such as quick search of edge, centers and datum marks.

> Rich color graphic (the same resolution as a PC screen).

> Automatic multi-step machining (coarse, medium coarse, medium fine, fine, superfine)—up to 10 steps.

> Unlimited number of machining conditions can be saved as machining archives. Each set of machining conditions can be edited, modified or stored. They are easy to edit and easy to find.

> Automatic origin search and multi-point coordinate memory capability.

> 1/2 design capability, ARC automatic discharge waveform detection and automatic adjustment.

> Automatic center position detection, automatic compensation, search of hole center and deepest point; fixed hole machining (cyclic mode, independent mode), which is suitable for different machining conditions; Radial, circular, square, linear (vector), coning, 45° hole-expanding machining.

> Three-axis beeline, two-axis arc, three-axis helix.

> Chinese/English versions interface, metric/British system switch and Z-axis quick up, quick down, slow up and slow down capability.

> Lateral machining, three axes, six directions (plane rotation).

> All alarms describe the source, date and exact time of problem occurrence.

> Optical scale is applied for close-loop position control, enabling extreme position for machining.

> Automatic editing—settings can be done according to type of material, work piece size, machining depth, one side die clearance, final current and rate of electrode wear.

> CNC models possess conventional capability of consistent level of energy discharge, achieving stable and rapid machining and smooth high quality on machining surface while the rate of electrode wear is still low.

> Monitor page indicates machining path and orbital pattern in use.

VISION WIDE TECH CO., LTD.

Product Description :

One of the proudest products of Vision Wide which fulfills automatic 5-face machining with super rigidity structure and high positioning accuracy. HF satisfies demands in mold surface cutting, angle cutting, 3D mold cutting, and precise contour finishing.

MATRIX PRECISION CO., LTD.

Product Description :

GHP-3540 applies the FANUC controller and high speed grinding spindle, through the in-house developed intelligent conversation window software, it can flexibly output the required tooth profile and grinding parameter. The machining workpieces include the involute gears and cycloidal gears, the high efficiency and high precision expressed from the product are equivalent to worldwide top brand's ones. GHP-3540 is your best choice.

JARNG YEONG ENTERPRISE CO., LTD.

Product Description :

1. Our main economical machine type with high processing efficiency, the price is more affordable than swiss type, it's an entry models for CNC lathe.

2. The box way configuration is suitable for medium/heavy cutting. The base of the fuselage is cast and formed. It is relatively strong and strong.

3. With X/Z axis large travel design, wide of span, more robust and stable processing, easy to tool arrangement.

4. Can be used with the bar feeder for automatic processing without interruption, and can also be customized for single-piece automatic feeding.

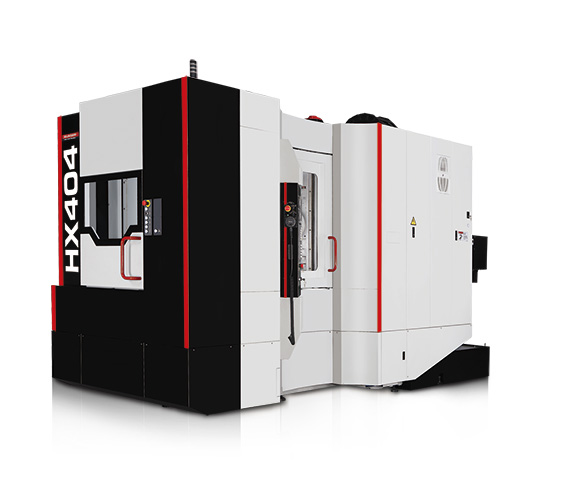

QUASER MACHINE TOOLS, INC.

Product Description :

The large Z axis span of HX404 allows the machine to deal with high work pieces and to strengthen machining stability with high rigidity.

The HX404 utilizes W-shaped Z axis telescopic covers to deal with stacked chips, combined with the integrated coolant wash, internal chip augers and external lift up chip conveyor, enhances the management of chip disposal.

In addition, the easy operation and ergonomic accessibility for HX404 allow s operator easily to reach machining work piece, spindle and load/unload station. The HX404 also features small floor space, which makes the best space utilization for clients.

G-TECH INSTRUMENTS INC.

Product Description :

To reduce damages caused by accidental collision, and to record collision events.

✓ Smart monitoring box consisting of sensors & electronics

✓ High bandwidth MEMS tri-axial accelerometer (X, Y & Z)

✓ Relay triggered in less than 1 millisecond upon a collision

✓ Built-in data log for max. 5,000 collision events

✓ Easy installation on machine structure

✓ Easy software for threshold setting & logging

✓ Economically priced

JEFFER MACHINERY CO., LTD.

Product Description :

JF-40S is a universal grinder with accuracy grinding technology. It can grind variety of woodworking knife tools, such as woodworking grooving cutter, shank router bit, finger jointer cutter and so on.

On the other hand, 40S is the most important metalworking machining machine tool which can grind knife tools used by Lathe and milling machine, if you need grind variety of machining metalworking knife tools, 40S is the best choice. JF-40S is a precise grinder with multifunction capability and also owns attractive pricing. Besides, JF-40S owns unique function that it is indispensable for broaching machine knife tools.

In addition to JF-40S, we do have JF-60S, JF-150S that is adjusted available on request.