Theme

Digital Transformation

Green Transformation

JARNG YEONG ENTERPRISE CO., LTD.

Product Description :

1. External auto loading/unloading SPM

2. Its feeding capabilities are O.Dφ6~φ35 mm, max length 40mm.

3. Its feeding mechanism is placed outside of machine to keep mechanism from chips and oil stain.

4. Adjustable guideway is suitable for round/hex shape workpiece alone with rotary cylinder and fixture, which can make hex material positioning in short time.

Ametek Taiwan Corp., Ltd.

Product Description :

Autocollimator:The autocollimator is used for measuring angle, straightness, flatness, squareness and parallelism.

MAT:The micro alignment telescope is used for alignment inspection and adjustment in machine tool and ship industries.

Talyvel:The Talyvel electronic level is used for measurement and adjustment, such as: straightness of machine tool guideway, flatness of granite platform.

Clinometer:Precision in angular measurement, checking and setting with 360° range.

Prism Checker:Automatic Prism/Polygon measurement system.

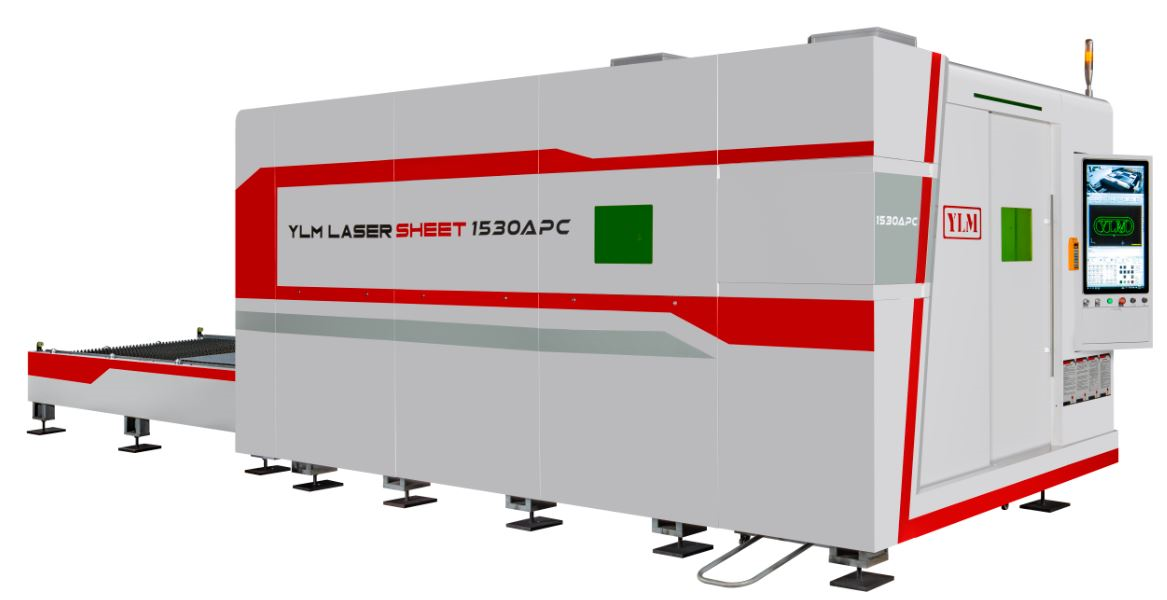

YING HAN TECHNOLOGY CO., LTD.

Product Description :

Suitable for cutting various metal sheets

■Maximum cutting thickness of metal sheet varies with the laser power.

■Upon customer request, the machine can be designed with a work piece platform as mechanism(optional). It helps to reduce work piece loading/unloading time, which in turn upgrades operation efficiency.

■Large laser power, high efficiency and high productivity.

■Equipped with an intelligent digital controller featuring humanized control, which is easy to learn and operate.

■The specially designed software allows the operator to design the graphs on characters with ease, then machining can be conducted immediately.

■Enclosed splash guard

■Fast machining, power saving, outstanding safety protection, low trouble and easy maintenance.

For cutting commonly used metal sheets such as:

■Carbon steel sheets

■Alloy steel sheets

■Galvanized steel sheets

■Stainless steel sheets

STAND TOOLS ENTERPRISE CO., LTD.

Product Description :

◎ Two tones of a loud buzzer are easily recognized when closing the target torque

◎ A large LCD and a stable torque increment avoid misreading, which is often occurred

with mechanical torque wrench. LED lights are flashing when closing the target torque.

◎ The square or round handle is vibrating when reaching the target torque.

◎ Unit conversions are automatically made among Nm, Ibf-ft, Ibf-in, and kgf-m.

◎ The DG-ll@ digital torque wrench has the capacity to store up to 32 torque values in

memory, and can be reviewed easily after working.

Optional

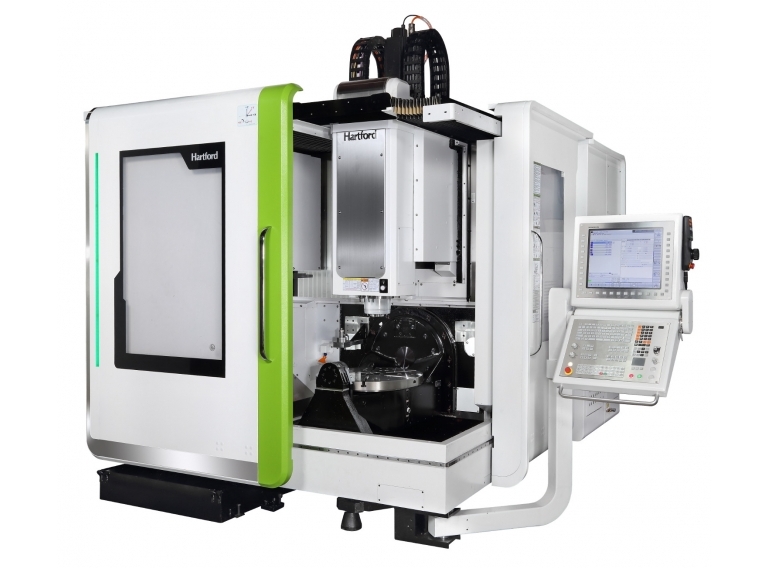

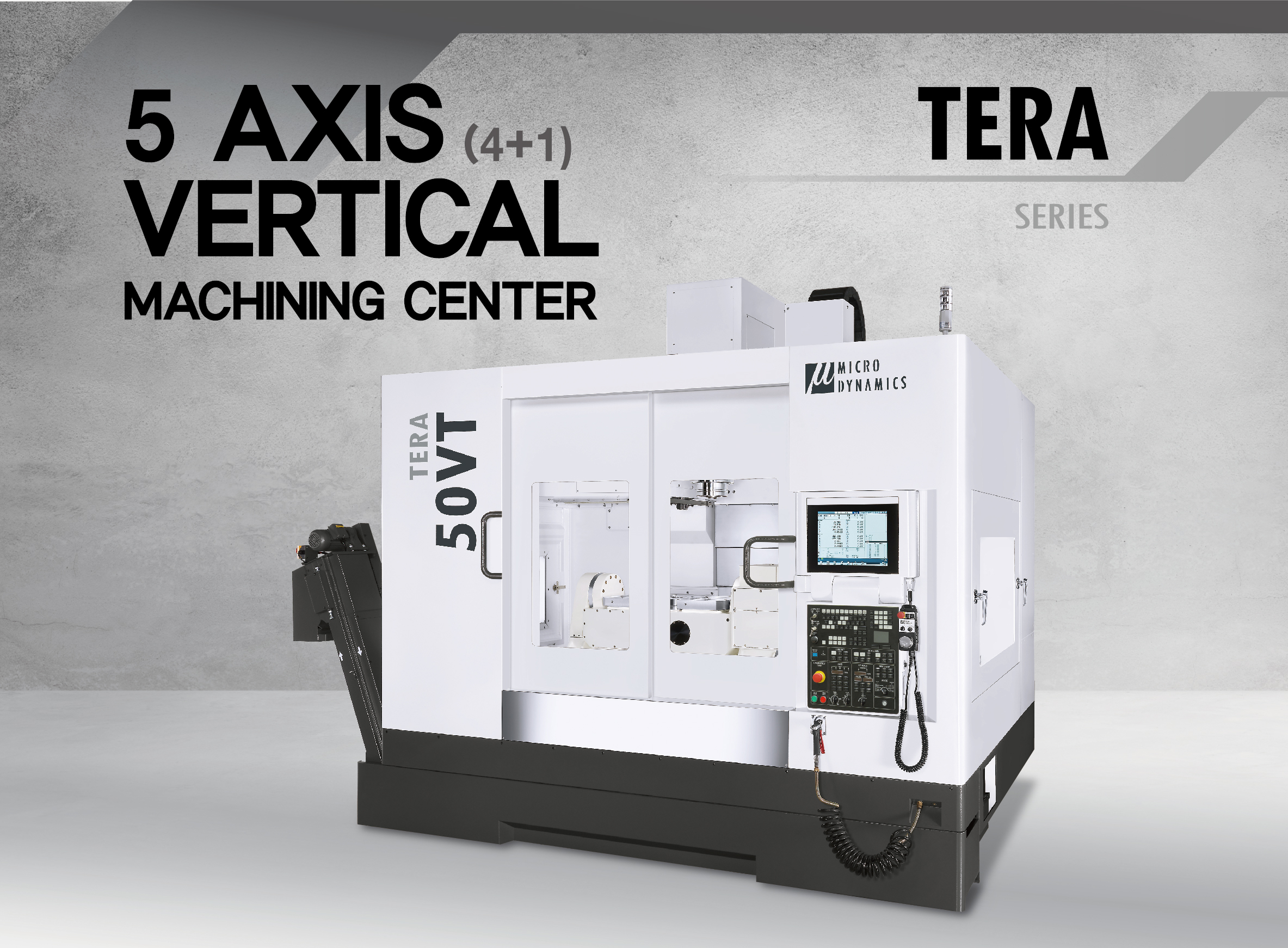

INNOSERV FA INC. TAIWAN BRANCH (BVI)

Product Description :

Micro Dynamics Vertical Machining Center Line opens a new era in multi-purpose and versatile machining centers. Compact, durable, powerful, strong and accurate, the MEGA/TERA Series starts a revolution in the market: the smallest C-frame machines provide powerful and precise results for manufacturers of dies and molds, aerospace, automotive, semi-conductor, job shops and general machine sectors.

The MEGA/TERA Series has been designed with the latest in technology being utilized throughout the machine with productivity in mind. From its EtherNet/IP architecture for easy automation and integration into systems and cells, to its Motion Control for fast and smooth operations used in all industries, the MEGA/TERA Series has quickly become one of the industries leading machine tool lines of Vertical Machining Centers.

The MEGA/TERA Series has been refined through years of research and development of new technologies that greatly enhance the machines for the rigors of the Mold and Die industry.

All series are equipped with

■ 15,000 rpm Built-In Spindle

■ Thermal Compensation (DYPEC)

■ Micro Dynamics HMI

FALCON MACHINE TOOLS CO., LTD.

Product Description :

These words describe the driving forces behind the design of our SMART-IV CNC surface grinding machines. They’re the standards required by the medical, automotive, mining, semiconductor, aerospace, injection mold making and job shop industries in order to meet current and future market needs and pave the way to factory automation.

This series is capable of producing complicated shapes for highly accurate workpieces along with finer finishes. The heavy-duty slide rails, one-piece base casting and hardened wheelhead guideways create a solid, rigid machine structure that minimizes vibration, movement and displacement.

Chevalier’s user-friendly grinding machines include our exclusive PC-based SMART iControl featuring conversational programming.

Combined with TaskLink, it allows operators to create their own programs for generating complex grinding tasks in a single cycle—without an engineering degree.

MONGTEC PRECISION INC.

Product Description :

◎ The general spindle speed is only 6000-15000rpm, and the tool can be pushed up to 55000rpm through 15-70bar coolant pressure, saving 70% of cycle time

◎ Various interfaces can choose BT/HSK/ER/PCS/straight

◎ Tool can be changed by ATC

◎ Display processing tool speed with chip transmission

◎ Excellent run out within 0.003mm