Theme

Digital Transformation

Green Transformation

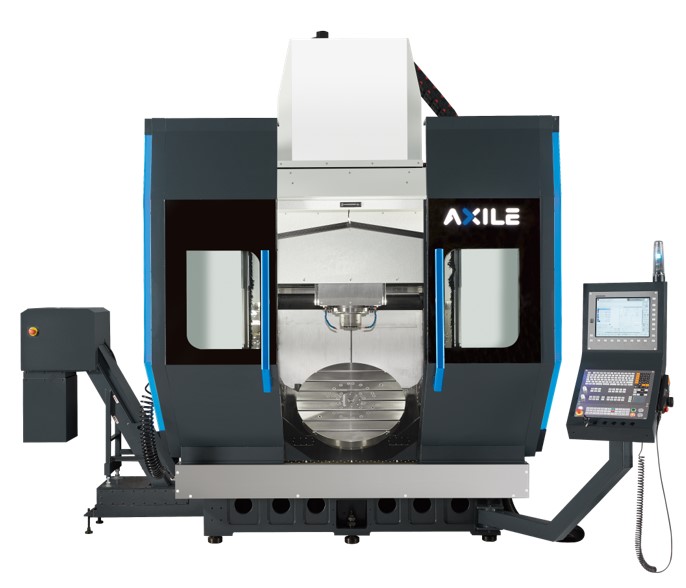

BUFFALO MACHINERY CO., LTD.

Product Description :

The AXILE G8’s powerful gantry design perfectly balances rigidity and precision, ideal for the machining of complex workpieces.

With a maximum loading capacity up to 1,300 kg on a swiveling, rotary table, complemented by high-performance built-in spindles, the G8's agility enables production of a wide range of large parts and tools.

The G8 MT option offers both milling and turning in one machine, greatly increasing operational flexibility. By reducing set-up times and potential clamping errors, the G8 MT can efficiently machine a wider variety of parts, including cylindrical components.

SHENG YU PRECISION MACHINE CO., LTD.

Product Description :

The general-purpose two-way horizontal CNC drilling and tapping machine can be combined with various industries to provide the best processing solution for multi-axis machine tools to improve efficiency and reduce costs. It is a processing tool that belongs to you.

GREEN ECO PRO CO. LTD.

Product Description :

Chip Vacuum Removal System

FC Series

Used by Negative vacuum principle, and increase high absorption of air to get filter cycle. Intercept particulate matter and impurity.

Processing cycle

Zero Power consumption

CNC Machine No Stop

Waste material a few water

No Consumable

Reduce wastage of coolant

Promote Volume of Water Tank

Promote productivity

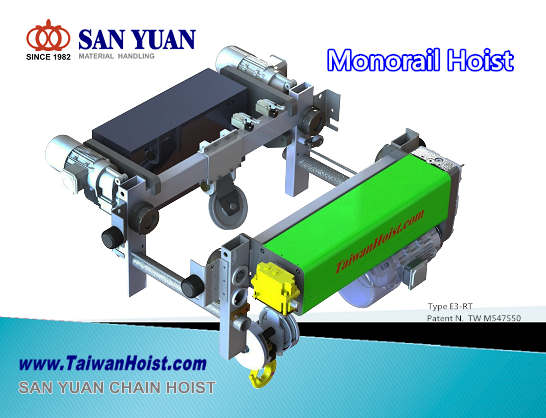

SUNG YANG MACHINERY CORPORATION

Product Description :

SAN YUAN Monorail Low Headroom wire rope hoist

●Hoisting Brake – disc brake having the braking torque >150%rated torque of motor .

●The brake is holden even if power failure - ensuring the load isalways stopped when the control button is released.

●Gears are smoothly operated for an oil bath lubrication and superior to a wear and abrasion resistance.

●Fine machining of the drum grooves minimizes wear on the rope, the return sheaves are resistance to wear.

DAH LIH MACHINERY INDUSTRY CO., LTD.

Product Description :

T型結構床台設計。<br />

X, Y, Z軸滑軌均採用鑄鐵批覆合金鋼方式一體鑄造成型,以提昇硬度、耐磨性、吸振性及防鏽性,以重切削能力為訴求。<br />

三軸皆採用預拉式滾柱導螺桿,可減少熱變形,提高定位精度。<br />

齒輪傳動,有二檔變檔功能,在302rpm時即可達到全馬力輸出。<br />

主軸及傳動齒輪採強製冷卻,可降低溫度,提申精度。<br />

主軸頭部與立柱滑道面為8面接觸,以提高剛性,在重切削時獲得最高的穩定性。<br />

主軸頭部為左右兩側對稱設計,可將溫度產生的熱變形降至最低的程度。<br />

穿梭式自動交換工作台,腳踏迴轉裝置。<br />

油壓系統,刀臂夾持自動刀具交換裝置(A.T.C),鍊式雙向迴轉刀盤結構,就近選刀。<br />

浴池式自動交換工作台(6 A.P.C)。<br />

<br />

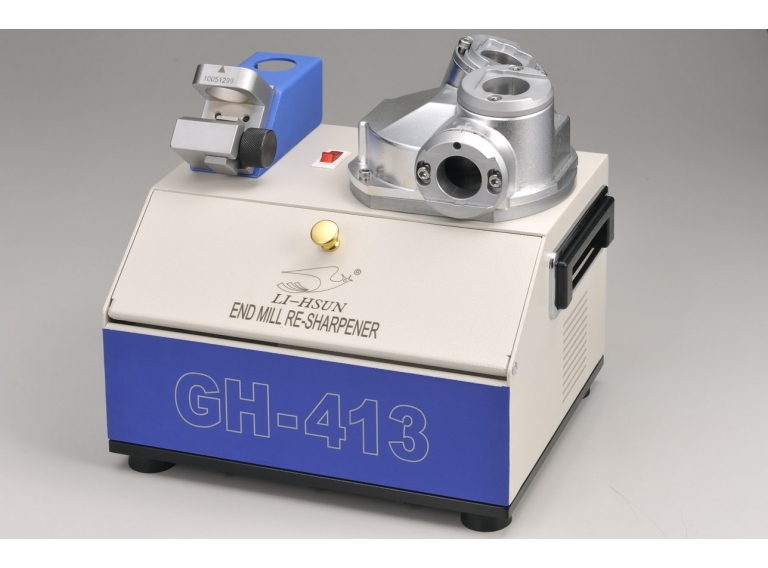

CHING HSYANG MACHINERY INDUSTRY CO., LTD

Product Description :

1.A circular tube modifies an interior angle and an external angle at one time with fastness and precision.

2. It's simple and fast to switch the knife because of easy to buy the insert disc in the market.

3. Two-stage of feeding knife, and the idle stroke is smooth. It's available for adjusting the operation stroke according to the cutting volume.

4. There are automatic and manual functions, which are convenient for adjusting the machine.

5. Special automatic positioning device, which can automatically position, feed and chamfer, and fine-tune the length tolerance.

6. Oil mist cooling and lubricating system promotes insert life, and no chips will stay.

7. There is a pause switch at the final point so as to assure the flat plane and the accurate right angle of the work piece.

8. The axle head with phosphor & copper bushing can prolong the life.

9. It can be option the lifting rack to use with this machine.

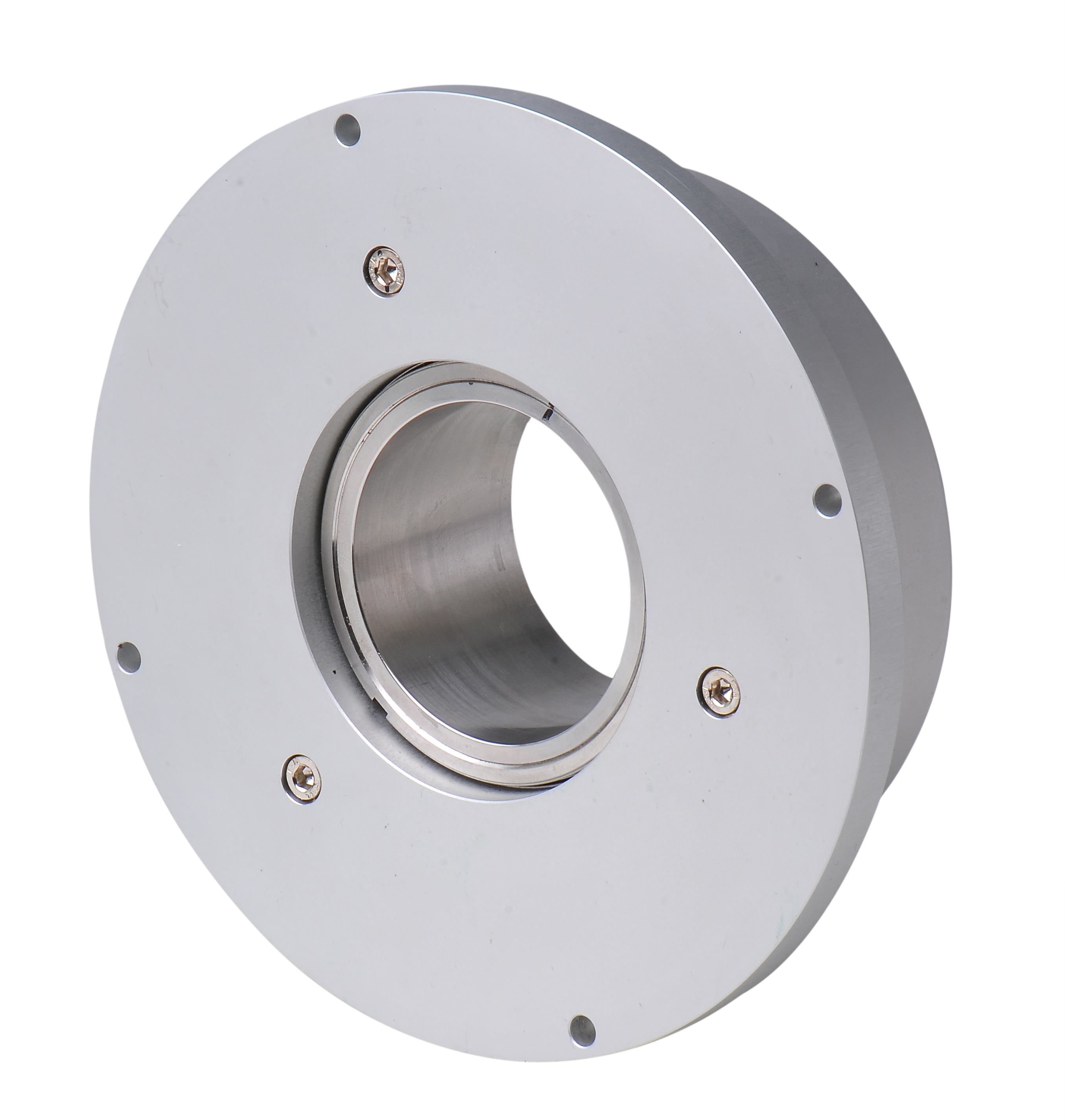

BUFFALO MACHINERY CO., LTD.

Product Description :

Available with two or six pallets, AXILE’s automated G6 Motorized Pallet Changer (MPC) exchanges raw workpieces and finished parts via a loading bay at the back side of the machine. Operators can load raw workpieces, and inspect and unload finished parts, while machining continues in the vertical machining center 24/7, dramatically increasing operational efficiency.

Freedom and flexibility are core to the design concept, as the MPC solution can be inte-grated upon initial commissioning of the G6 machine, or at a later stage when production capacity expands. And with the MPC-2 (the two-pallet solution), manufacturers can em-brace a Flexible Manufacturing System (FMS), of 12, 24, or 36 pallets total, by integrating one to three machines and two loading stations, depending on the scale required.

With AXILE’s digitalized intelligent automation solutions, manufacturers can eliminate production bottlenecks and ramp up production.