Theme

Digital Transformation

Green Transformation

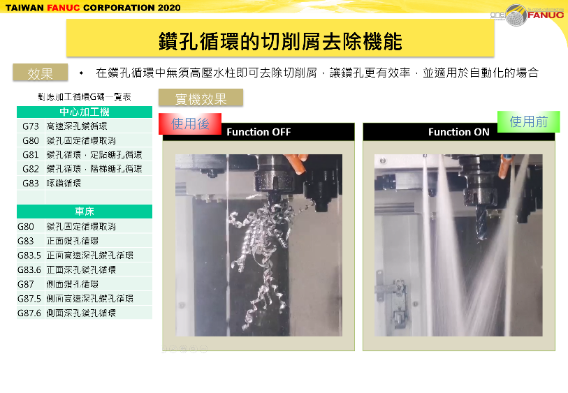

TAIWAN FANUC CORPORATION

Product Description :

Machine center chips entanglement has always been the biggest subject of automation.

Entanglement can cause problems such as suspension, failure, and workpiece defects on the machine.

The servo learning oscillation function can effectively solve the chips entanglement problem, minimize the chips and realize the realm of automation.

HO CHEN MACHINERY & ELECTRIC IND. CO., LTD.

Product Description :

X axis travel:

Single movement: 1125 mm (44" )inch

Dual movement: 560 mm (22") inch

YZ axis travel 700x500 mm (28"x20") inch

Work table: 1850x850 mm (73"x33") inch

Max. Workpiece: 2800x1400x700 mm (110"x55"x28") inch

Max. Workpiece weight: 5800 kg

Max. electrode weight: 400 kg

Machine net weight:8350 kg

Oil level: 110-550 mm (4"-22") inch

Packing size(LxWxH): 5430x4600x3090 mm (214"x181"x122") inch

Work Table to platen: 700-1200 mm (28"-47") inch

Filter: 4

Paper filter:8

Capacity:3400 Liters

Machine Features

> Windows CE controller

> A dialog window with picture description.

> Special repaired frames to quicken the maintenance speed.

> Close-loop design of digital feedback on three axes of the machine significantly increases positioning precision and ORBIT-CUT machining accuracy and efficiency.

> Simple operation interface.

> Common function keys are located on the operational panel for direct use.

> Hot key setting.

> ATC (automatic tool change) and C-axis 360° index can be installed; the process of coarse machining to ultra-fine machining can be completed at one time.

> Dialogue diagram provides various hole-expanding modes such as quick search of edge, centers and datum marks.

> Rich color graphic (the same resolution as a PC screen).

> Automatic multi-step machining (coarse, medium coarse, medium fine, fine, superfine)—up to 10 steps.

> Unlimited number of machining conditions can be saved as machining archives. Each set of machining conditions can be edited, modified or stored. They are easy to edit and easy to find.

> Automatic origin search and multi-point coordinate memory capability.

> 1/2 design capability, ARC automatic discharge waveform detection and automatic adjustment.

> Automatic center position detection, automatic compensation, search of hole center and deepest point; fixed hole machining (cyclic mode, independent mode), which is suitable for different machining conditions; Radial, circular, square, linear (vector), coning, 45° hole-expanding machining.

> Three-axis beeline, two-axis arc, three-axis helix.

> Chinese/English versions interface, metric/British system switch and Z-axis quick up, quick down, slow up and slow down capability.

> Lateral machining, three axes, six directions (plane rotation).

> All alarms describe the source, date and exact time of problem occurrence.

> Optical scale is applied for close-loop position control, enabling extreme position for machining.

> Automatic editing—settings can be done according to type of material, work piece size, machining depth, one side die clearance, final current and rate of electrode wear.

> CNC models possess conventional capability of consistent level of energy discharge, achieving stable and rapid machining and smooth high quality on machining surface while the rate of electrode wear is still low.

> Monitor page indicates machining path and orbital pattern in use.

TAIWAN MACHINE TOOL CO., LTD.

Product Description :

Strong casting and the perfect boxway stucture provides excellent cutting capacity for TTB-20MW Series. Sub-spinfle with milling function and Y-axis can satisfy customers' miltiple needs.

-The one cast base incorporates FEM analysis to achieve its optimal ribbing and structure to further enhance machine rigidity and stability.

-The 30 degree slant bed design has low center of gravity for easier swarf management and better erogonomic design. The TTB-20MW Series also offer optional rear type chip conveyor.

-To make sure the usage life of Y-axis ballscrew will get longer, there are three bearing on Y-axis ballscrew to enhance the support for pressure from top.

-The TTB-20MW Series can achieve maximum 20m/min for X axis and 25m/min for X axis. And the servo motors adopt absolute encoders for faster and more reliable positioning.

Giant Red-Wood Int’l & Co. Ltd

Product Description :

RW-600A Hydraulic Riveting Machine (Mitsubishi 10” HMI)

(Without Feeding System)

-Safety Device to protect finger get injured

-Proportional Value Control System

-Double-Pumps hydraulic Designed

-Auto-Riveted Counting to avoid missing riveted

-Mitsubishi 10” HMI

-Control System: Mitsubishi PLC

-Pressure Range:2-53KN(6T)

-Horsepower:3HP

-C type throat depth:450mm

-C types throat height:400mm

-Power Voltage:220V Three-Phase

*Mitsubishi 10” HMI can ensure the pressure during the operation. It also can auto-check for faulty.

*Suitable Rivet:Nut up to M10, Bolt up to M8, FH Screw up to M6 (Carbon Steel)

* Proportional Value Control System: Specific Pressure adjust bottom designed, can adjust correctly pressure within 10 second, precision within+/-1%.

*Positive Stop System: Designed for soft working pieces to ensure the flat surface. Thickness accuracy up to +/-0.05mm

*OMRON 5” HMI can ensure the pressure during the operation. It also can auto-check faulty.

*Suitable Rivet:Nut up to M10, Bolt up to M8, FH Screw up to M6( Carbon Steel)

*Pressure control easy to operate: Specific Pressure adjust bottom designed, can adjust correctly pressure within 10 second, precision within+/-1%.

*Positive Stop System: Designed for soft working pieces to ensure the flat surface. Thickness accuracy up to +/-0.05mm

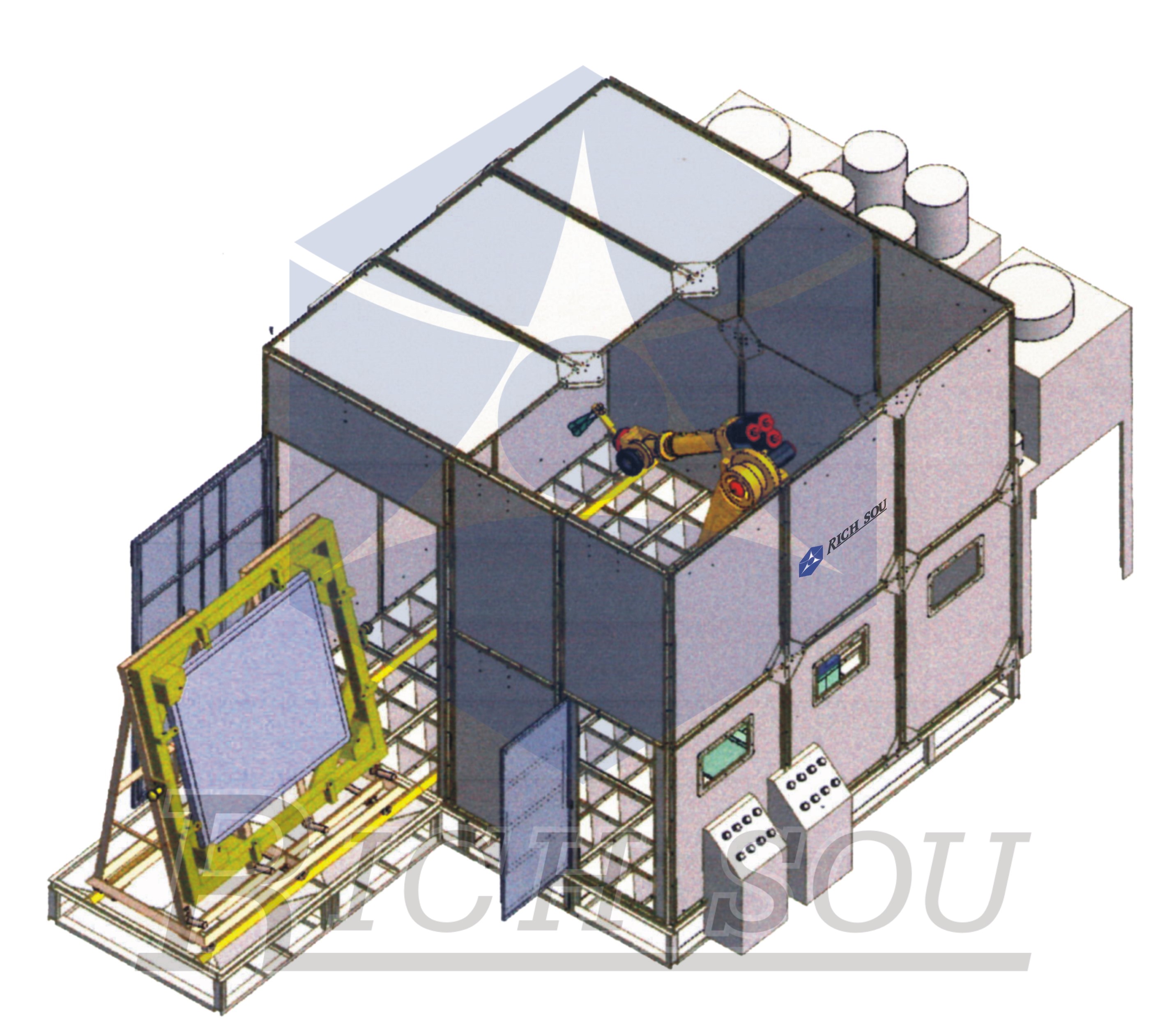

RICH SOU TECHNOLOGY CO., LTD.

Product Description :

Rich SOU blast room provides even greater potential for improving safety and reducing operating costs when you're cleaning, finishing or surface-profiling large work pieces. With the process contained in a specially designed enclosure, blast media and debris are separated from the external environment. And the operator, equipped with safety gear, is fully protected.

PALMARY MACHINERY CO., LTD.

Product Description :

The new CNC internal Grinding Machine from PALMARY features optimal structural design, and an elegant appearance combined with advanced CNC control. The all new series will bring internal grinding technology into a new era. The structural parts of the machine are manufactured from high quality cast iron for deformation-free performance year after year. The entire machine is precision built throughout to guarantee the best possible grinding accuracy you can find anywhere.

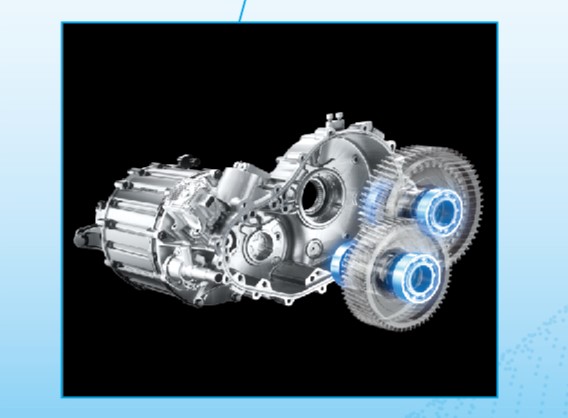

HSU PEN INTERNATIONAL PRECISION MACHINERY CO., LTD.

Product Description :

*Employs high rigidity, extra large radial and axial bearing.

*Equipped with special labyrinth type multi-piece disk brake that provide multi-surface braking. Big area design effectively increases clamping force. The table structure eliminates table surface floating problem.

*Big hole design makes machining more convenient. Manufactured from high quality, durable cast iron. Increased body thickness increases load resistance capability. Large through-hole diameter. High strength, heavy cutting resistance as well as high precision.