Theme

Digital Transformation

Green Transformation

CHIAH CHYUN MACHINERY CO., LTD.

Product Description :

■No matter what operation – turning, milling, drilling, tapping, cutting, side turning and back machining, the

CB series does it all in one operation.

■Sliding head without a guide bush design provide faster setups, lesser remnants, and more cost reduction.

■The CB series provide multiple tooling systems is suitable for versatile cutting applications. On the front side

tooling system, user can set with 4+3 live tools, 6 O.D. tools and 5 I.D. tools. Moreover, on the back milling

system, user can set 4 live tools. The maximum tool speed is 6000 rpm. User can install O.D. and I.D. tools

on the back milling system.

■The sub-spindle head moves on the precision roller type linear ways with extra-large span design for

outstanding stability and positioning accuracy.

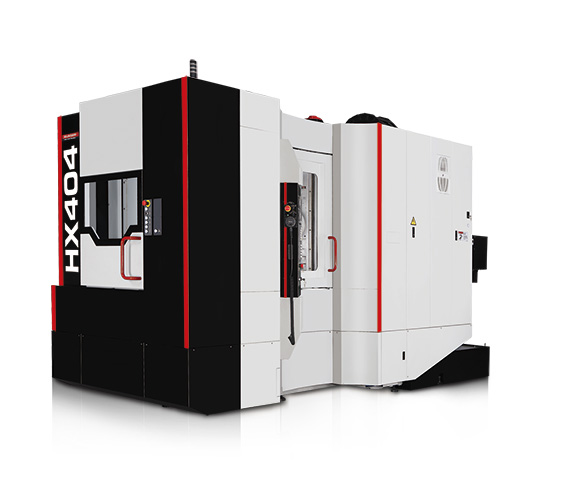

QUASER MACHINE TOOLS, INC.

Product Description :

The large Z axis span of HX404 allows the machine to deal with high work pieces and to strengthen machining stability with high rigidity.

The HX404 utilizes W-shaped Z axis telescopic covers to deal with stacked chips, combined with the integrated coolant wash, internal chip augers and external lift up chip conveyor, enhances the management of chip disposal.

In addition, the easy operation and ergonomic accessibility for HX404 allow s operator easily to reach machining work piece, spindle and load/unload station. The HX404 also features small floor space, which makes the best space utilization for clients.

WEXTEN PRECISE INDUSTRIES CO., LTD.

Product Description :

■Single refrigerant circuit is with multiple oil circuits, and it provides independent flow rate and pressure precisely.

■ Different liquids can be controlled temperature at the same time,and it can be customized.

■ Temperature control of Dual-PCB for each of plural circuits and it can adjust temperature individually.

■ It has temperature compensation and preheated function.

■ Temperature control precision is +0.5~1.5 ㆍC. (It can be customized of other temperature control precision.)

■ Saving about 50% of floor space.

■ Using high-efficiency environmental refrigerant and without pollution.

■ Up-to 95% materials of machine are recyclable and eco-friendly.

TAIWAN MORE-CASH VILLAGE CORP.

Product Description :

1.Convenient Design

X, Y axis workable professional structure enhanced high-

performance cutting accuracy.

2.Cutting Capacity

Cutting diameter: Ø3~16mm;

Cutting length of work-piece end: 15mmL/max;

3.Patented Radius cutting by Dual-motor driver

The hardened treatment steel is controlled well in virtue of

natural dissipation characteristic, cutting time is greatly

shortened as the work-piece is simultaneously rotated while

cutting.

4.Quick-Work-Changing System

The work-piece is quickly exchanged with prime quality 3-Jaw

chuck system.

5.Cooling System

Dry cooling is able to connect with various pressurized air and

vacuum cleaner achieved perfect cooling effect.

6.Cutting Disc

SD#100 for Carbide, CBN#100 for HSS

7.Optional Grinding Wheel For GS-13 GS-13

SD#100 thickness 5mm, 10mm for Carbide, CBN#100

thickness 5mm, 10mm for HSS

A.Carbide end mill cutting efficiency on GS-13

■ Ø 10mm 4 flute carbide end mill is cut by SD#100 cutting

disc takes 55 seconds.

■ Ø 16mm 4 flute carbide end mill is cut by SD#100 cutting

disc takes 100 seconds.

B.HSS end mill cutting efficiency on GS-13

■ Ø 10mm 4 flute HSS end mill is cut by E60WA cutting disc

takes 60 seconds.

■ Ø 16mm 4 flute HSS end mill is cut by E60WA cutting disc

takes 110 seconds.

HONG JI PRECISION MACHINERY LTD.

Product Description :

This machine is equipped with 4 spindles and auto loading & unloading system is for mass production.

HAWE Hydraulik Singapore Pte. Ltd. Taiwan Branch

Product Description :

Compact hydraulic power packs are a type of hydraulic power pack. They arecharacterised by a highly compact design, since the motor shaft of the electric drive also acts as the pump shaft. Compact hydraulic power packs are designed to supply hydraulic circuits with hydraulic fluid.

The compact hydraulic power pack type INKA consists of the tank, the integrated motor and the radial piston pump or gear pump directly attached to the motor

shaft. The directly mounted electronic communication box with integrated realtime operating system allows the operating state to be recorded and visualised. The

measured values of the integrated multi-sensor (including the motor speed) can be passed on to the higher-level machine controls via standardised interfaces and processed there.

The consistently modular design of the type INKA means that different usage volumes and delivery flows can be realised quickly and easily from the modular

system. Compatible, ready-for-connection, complete solutions can be assembled easily using a wide range of connection blocks and the valve banks that can be combined with them.

Features and benefits

■ Prepared for condition monitoring with integrated sensors and communication box

■ Optimum efficiency through under-oil motor cooling, direct power transmission,and sophisticated heat dissipation

■ Suitable for nominal operating modes S2 (short period operation) and S3 (periodic intermittent operation)

■ Resource-saving due to small oil filling volume

Intended applications

■ Machine tools and material testing

■ Hydraulic tools

■ Handling systems

■ Presses and processing machines

TAIWAN SPINFLO CO., LTD.

Product Description :

-Accuracy temperature Control at ±0.1℃, solve machine tool maker and manufacturing reduce machine’s life that running long time and high temperature.

-Continue using high-accuracy control let machines get more accuracy and do perfect products.

-Not only good performance but also can get high efficacy in different area.

HONG JI PRECISION MACHINERY LTD.

Product Description :

This machine is applied to deep hole reaming to reach high accuracy in hole roundness. It is suitable for reaming center holes of gun barrels and long shafts.

NINE-9 CUTTING TOOLS CO., LTD.

Product Description :

NC Helix Drill cuts material by helical interpolation; serrated cutting edge minimizes chip length.

Low spindle power is not a problem, good for drilling material that generates long, soft chips.

● Reduce Your Tool Inventory

Each holder can machine di erent diameters and hole depths, saving your tool inventory and cost!

No need to peck drill or dwell in operation even machine without internal coolant.

● Lower spindle power consumption Easy to cut!

• Thanks to the small cutting load of the serrated cutting edge and helical interpolation lower power consumption. Work quicker, smarter and achieve better results.

• Circular ramping milling, maximum ramping angle is 20°. For example: tool HD27 machining Ø50 mm hole, 9 mm pitch for aluminum, 6 mm pitch for carbon steel.

● Special insert geometry - exceptional swarfs control.

• Serrated cutting edge makes the chips short and small, and easier to evacuate.

• Eliminate swarf and vibration problems while drilling di cult material or deeper holes.

● “One tool” performs multiple applications

• Not only a drill, but an end mill too.

• Small radius path to cut a hole or step hole, various curved cavity shapes on di erent materials.