Theme

Digital Transformation

Green Transformation

JEFFER MACHINERY CO., LTD.

Product Description :

This machine comes in a one-piece construction that has been heat-treated to achieve maximum rigidity. The rails are thermal treated and precisely ground to reach hardness of more than HRC 60˚. Furthermore, options are available to adopt rails of various lengths to meet different knife grinding requirements. The machine length can be customized for specific needs from 1,600 to 4,000mm. Rough and finish grinding wheels can be controlled manually and automatically. The minimum grinding wheel downfeed amount is 0.005mm and the spindle is equipped with an automatic cooling system which ensures excellent cooling effect. The SSG-8 employs an automatic lubrication system for smoother operation and longer service life.

SSG-8 Feature :

1. Knife tools movement type.

2. After grinding by coarse wheel and fine wheel, knife

tools can be sharp.

3. Force cooling system on motor shaft obtains better

cooling effect for the knives.

4. Grinding wheel lifting seat is used by ball bearing screw,

it can adjust up and down movement in precision.

5. Water splash guard and coolant tank are made of

stainless steel.

6. Grinding Capacity (Magnetic Chuck) LxW :

2500x200mm

Dah Young Vacuum Equipment Co., Ltd.

Product Description :

Cutting tool Ion coatings improve the surface hardness and wear resistance of the workpiece to reduce the friction coefficient of the surface and improve the service life of the workpiece applied to various cutting tools (such as milling cutters, drills, knife, blades, etc.), and various hardware tools (such as screwdrivers, pliers, etc.).

Dah Young's hard coating equipment has a unique cavity design and power configuration, and can provide customized target point design to meet customer needs. It can also be equipped with a magnetic filter tube. The serial connection of the magnetic filter tube in front of each arc target can be adjusted according to customer needs, so as to increase the target ionization rate, reduce target particle adhesion, reduce production costs, and improve coating quality.

Please refer to:https://zh-tw.dahyoung.com/

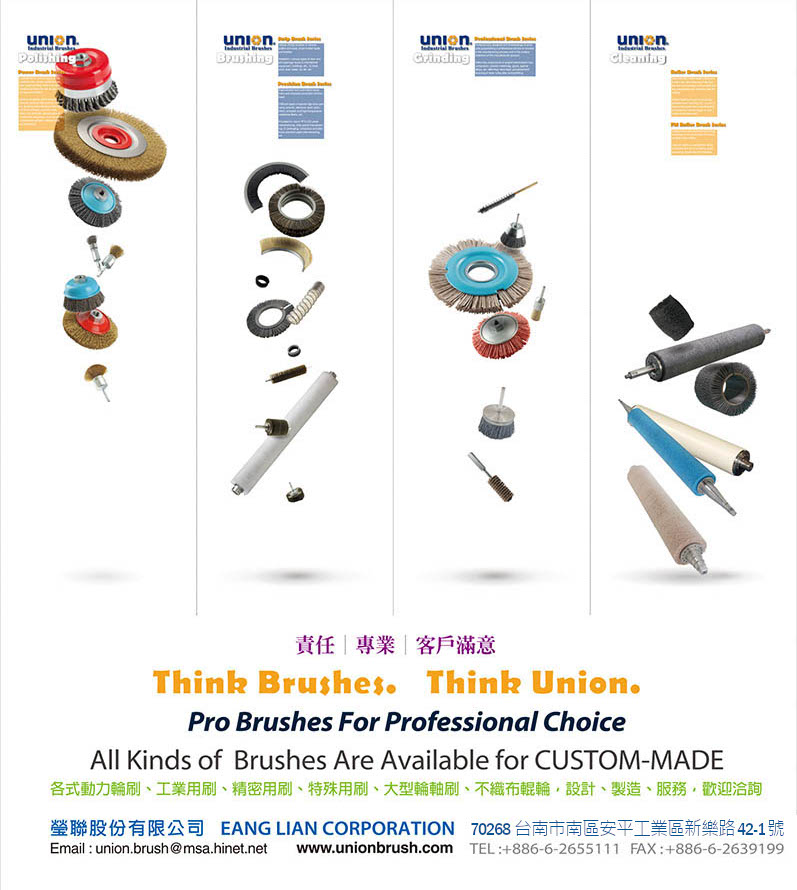

EANG LIAN CORPORATION

Product Description :

刷、磨、拋、洗<br />

專業化的設計能力<br />

多樣化的線材應用<br />

客制化的生產系統<br />

提供客戶製程製品-刷、磨、拋、洗.全方位的解決方案<br />

瑩聯股份有限公司—主要供應各式工業用刷是工業用刷之專業設計製造廠、擁有自有品牌(優利牌),產品適用於各行各業。無論需要刷洗、精細研磨、拋光、輕研磨、重研磨、毛邊去除、深孔加工皆有顯著效果!<br />

<br />

主要產品:<br />

1.動力輪刷系列適用於各型電動及汽動工具.<br />

2.矽砂尼龍研磨刷系列可針對各種表面精細研磨.<br />

3.輪軸刷及板槽刷系列接受各種線材及特殊尺寸訂製<br />

4.鋼鐵業退火酸洗、脫脂清洗、刷磨、清洗等大型刷輥<br />

5.德國技術合作專業生產高科技合成纖維輥適-用於鋼鐵軋片產線之刮油輥、塗油輥、擠水輥、張力輥、轉向輥、擠油輥、擠乾輥、擠壓輥、擠水輥、不織布擠水 輥。 6.各種線材及特殊尺寸可依照客戶需要量身訂製

RICH SOU TECHNOLOGY CO., LTD.

Product Description :

This machine is an improved model from the Y Rail model, featuring similar functions.

Designed standard with 4-station hanger with two side doors on blasting chamber. To meet your specific production line requirements, additional hangers are available for the entire working environment. Contact us for further details.

Features:

1.The machine employs a PLC controller for continuous cycles of blasting operation.

2.The cycle motions are: the hanging shaft enters the blasting chamber, and then moves to a fixed position at a lower speed. The door closes automatically.

Once the door is closed, the blade starts running automatically, and the machine performs blasting. Once operation is accomplished, steel balls are supplied and the blade stops automatically.

When the blade comes to a complete stop, the door opens automatically. When the door opens to the fixed position, the chain conveyor quickly delivers the nest hanging rod into the blasting chamber, then moves forward at a lower speed to a fixed position.

The door closes automatically and performs the nest cycle of blasting operation.

LEPAO ELECTRICITY MACHINERY CO., LTD.

Product Description :

Features

Double servo system, close-loop control , precision transmission, accurate in location

There are 6 combination of working coordinates in the system, it is convenient to design

programs and process workpiece

Showing location immediately, self-diagnostics and indicating error function

Providing with Start, Stop, manual fine-tuning, returning origin when it finished,

convenient to operate

Editing and modifying working program on controller

Chinese/ English switch , easy to operate

Supporting memory card, or USB to load files

The program can make by CAD/ CAM

Previewing route of working program

Control axis X , Y 6 axis maximum

Collocating with Pipe cutting, driller

8 inches LCD, a concise panel

Can install「Dust Collector 」

YIH KUAN ENT CO., LTD.

Product Description :

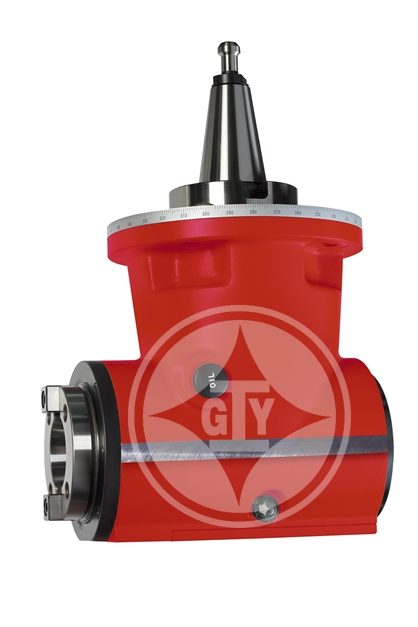

The CNC Milling Head can tackle all sorts of critical processes, such as rough milling, finishing milling, boring holes, and much more. It's easily compatible with a number of different machines, like computer gantry milling machines, machining centers, and so on. Don't let small spaces or tight curves slow down your projects - the CNC Milling Head is compact enough to fit even into the most complex of workspaces. Plus its precise performance ensures that you get results exactly how you need them - every time. With the CNC Milling Head you can take your machining to the next level while saving time and money in the process.

1. The IK milling head, which fits your current milling machines and special purpose machines, can take place of your current milling heads and upgrade your machines.

2. This product with gear-type construction is very powerful and can creat a maximum machining efficiency for you

3. Spindle speed change has high and low two stage.

4. This product can be installed to a computer-controlled vertical milling machine and a special purpose machine.

5. This products doesn't include a servo motor or servo controller.

6. The IK CNC milling head series has three kinds of products.

JAR HON MACHINERY CO., LTD.

Product Description :

1.Both cutting TAP and forming TAP are suitable.

2.Fully automatic machine so a person can operate many machines.

3.Gear-pitch type auto. tapping will get a precise & accurate thread for finished workpiece.

4.It can option to add inverter or use servo motor to control the spindle speed.

4. Especially suitable for light workpiece.

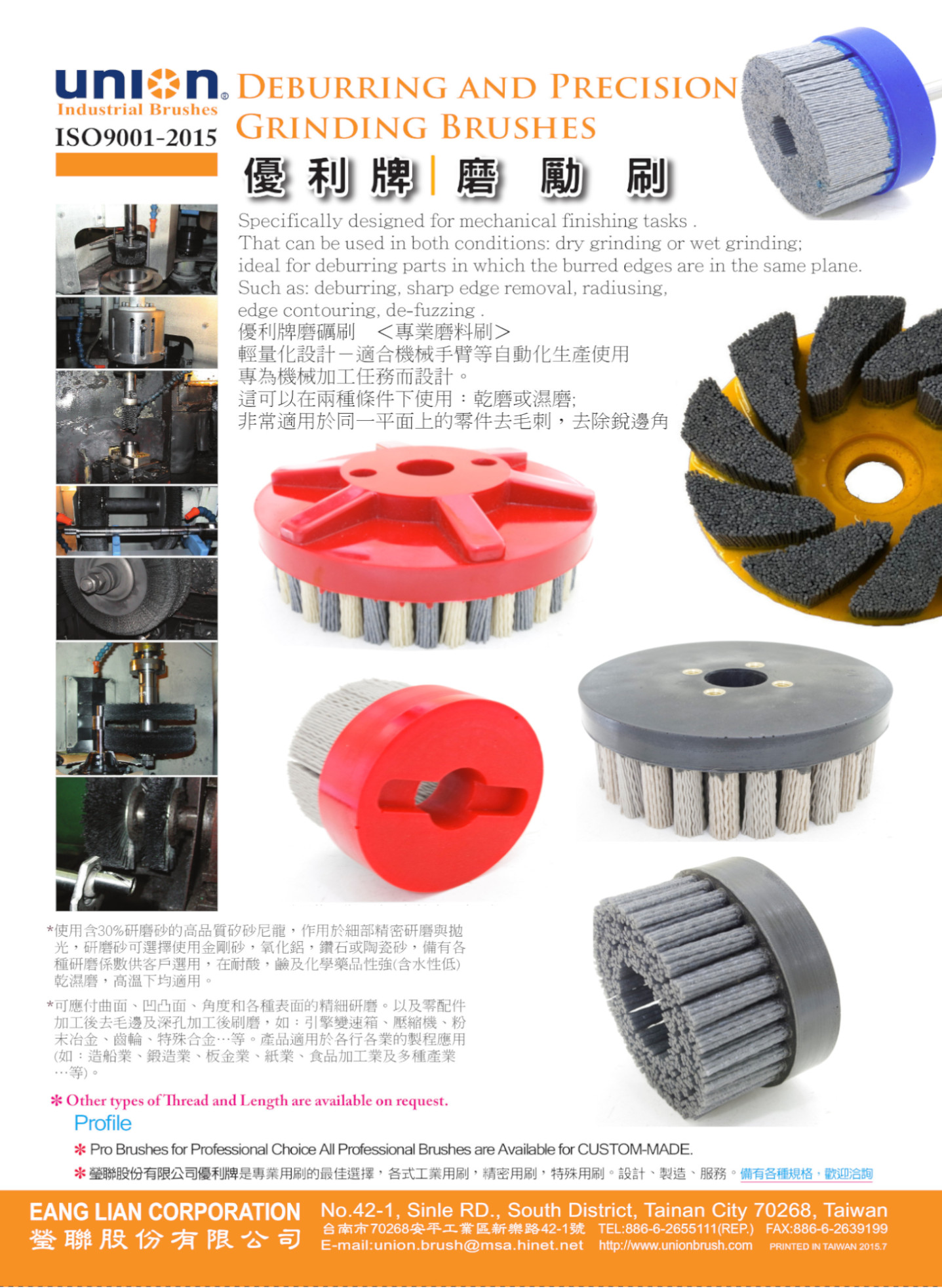

EANG LIAN CORPORATION

Product Description :

Professional Abrasive Brushes-Specifically designed for mechanical finishing tasks .

Specifically designed for mechanical finishing tasks .

That can be used in both conditions: dry grinding or wet grinding;

ideal for deburring parts in which the burred edges are in the same plane. Such as: deburring, sharp edge removal, radiusing,

edge contouring, de-fuzzing .