Theme

Digital Transformation

Green Transformation

Dah Young Vacuum Equipment Co., Ltd.

Product Description :

Cutting tool Ion coatings improve the surface hardness and wear resistance of the workpiece to reduce the friction coefficient of the surface and improve the service life of the workpiece applied to various cutting tools (such as milling cutters, drills, knife, blades, etc.), and various hardware tools (such as screwdrivers, pliers, etc.).

Dah Young's hard coating equipment has a unique cavity design and power configuration, and can provide customized target point design to meet customer needs. It can also be equipped with a magnetic filter tube. The serial connection of the magnetic filter tube in front of each arc target can be adjusted according to customer needs, so as to increase the target ionization rate, reduce target particle adhesion, reduce production costs, and improve coating quality.

Please refer to:https://zh-tw.dahyoung.com/

JEFFER MACHINERY CO., LTD.

Product Description :

ASG-800 is an Automatic Carbide Saw Grinder. Original design idea and goal is by the user-friendly, clear operation panel, the PLC numerical control and stores up huge tooth patterns inside it. The machine could grind different kinds of TCT saw blades and can store up common tooth patterns up to 100 groups. It has automatic compensation program to set up grinding wheel compensation. It also can adjust grinding speed and has automatic lubrication system. This is a multi-purpose Automatic Carbide Saw Grinder.

ASG-800 Feature :

1. Using Servo dividing on grinding wheel angle is fast

with high accuracy.

2. It can adjust high and low speed on grinding wheel up

and down movement, which can save working time.

3. Servo used on fixing position for pushing tooth with

precise and fast orientation.

4. With automatically right-left moving on grinding wheel

while working, this can reduce grinding noise and can

sharpen knives well.

5. Grinding capacity : dia.120~800

Saw blade bore diameter: dia. 10~85

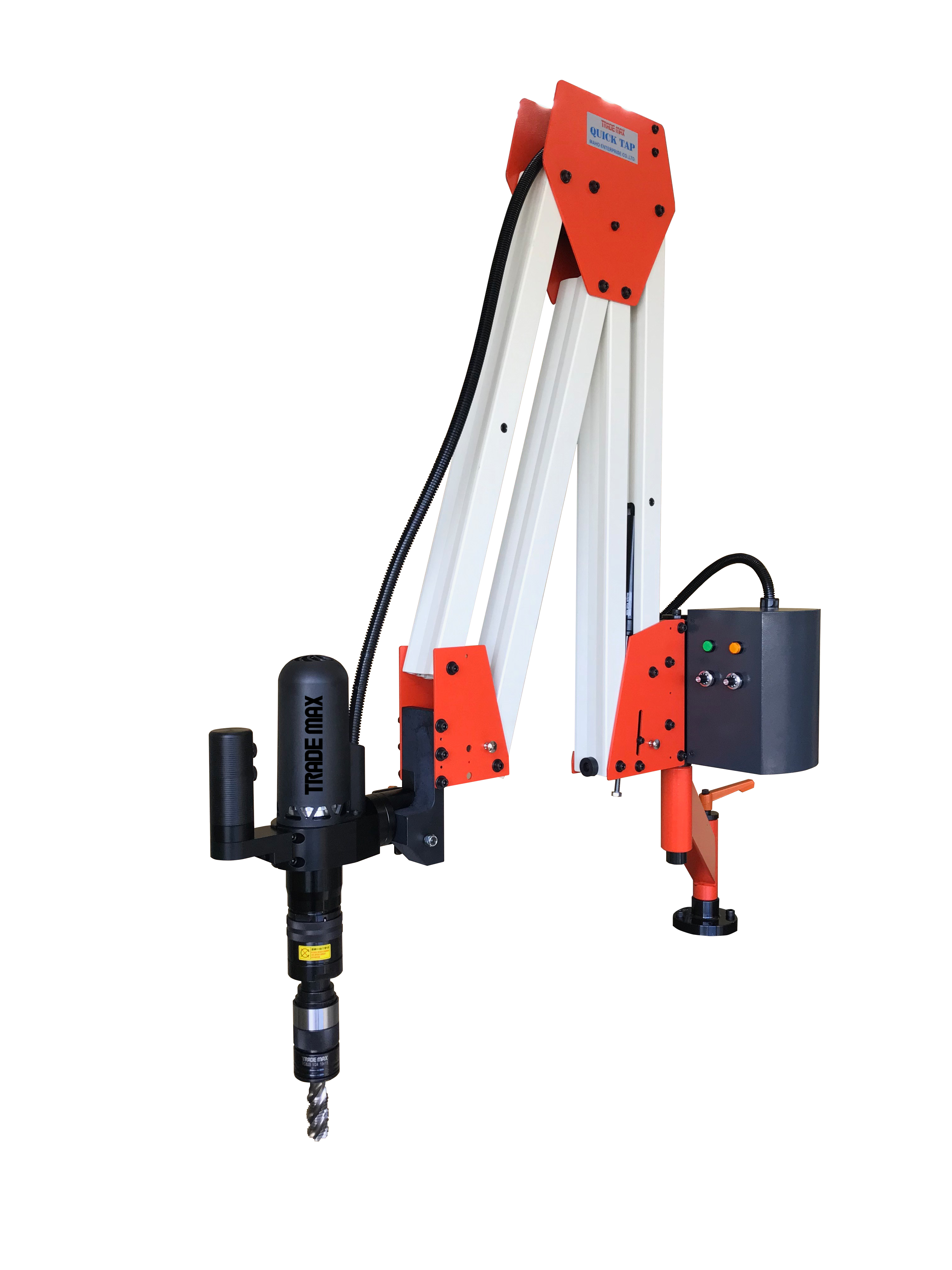

JAR HON MACHINERY CO., LTD.

Product Description :

1.Both cutting TAP and forming TAP are suitable.

2.Fully automatic machine so a person can operate many machines.

3.Gear-pitch type auto. tapping will get a precise & accurate thread for finished workpiece.

4.It can option to add inverter or use servo motor to control the spindle speed.

4. Especially suitable for light workpiece.

Taiwan Auto-Design Co.

Product Description :

// SolidMEN-300的優點

✅ 材料: 不綁材料僅建議合格廠商,未來可自行選用適合材料

✨ 雷射: 德國 500W 水冷式雷射穩定性佳

⚡ 層厚: 層厚可控範圍 10~100μm (最小進給單位 10μm)

🛠️ 成品: 可列印多種金屬材料,強度超過鑄造,可作為表面後處理及拋光使用

🔬 研發: 不綁參數開放製程研究,未來材料無受限可自行開發

⬆️ 尺寸: 300x300x300 可製作大尺寸工件,另有機型可增大或縮小

💎 緻密度>99.5%,品質優於鑄造,近似鍛造

🤖 搭配遠端資訊與智能化視覺模組,方便製程穩定性及智慧化整合。

(即時錄影、列印層數/高度、雷射功率、粉未剩餘量、腔體含氧量、製程時間等)

Dah Young Vacuum Equipment Co., Ltd.

Product Description :

High Power Impulse Magnetron Sputtering (HiPIMS) is a high-power pulsed power supply system used on magnetron sputtering coating technics. Compared to the traditional DC sputtering system, HiPIMS could generate tens of times higher pulsing current to obtain a ten thousand times higher-density electron plasma. Effectively enhancing the ionization rate to obtain a non-porous, high density crystallinity film at lower coating temperatures.

DAH YOUNG's DYHC HiPIMS series sputtering coater power supply and chamber cavity are designed to provide high plasma density (1018~19e-/m3) and high ionization rate (70~100%), increasing the substrate coating compactness, adhesion flatness and corrosion resistance. The lower duty cycle (<5%) results in a significant reduction in process temperature offering more substrate options on PEN, PET, etc. fiexible substrates.

Please refer to:https://zh-tw.dahyoung.com/

MAHO ENTERPRISE CO., LTD.

Product Description :

Electric tapping machine is suitable for different size taps (from M3 to M24). The machine is equipped with brushless DC motor and driver for controlling the spindle to tap. The arm is equipped with lubricated for life bearings at all swivel points, provides weightless operation through the use of gas counter balance springs and permits the operator to bring the tap to the hole with ease.

SPINTECH PRECISION MACHINERY CO., LTD.

Product Description :

●To meet the demand of processing hard and brittle material, toughness material, and dead soft material.

●To provide the cutting line speed for the tool of micro machining to increase high yield rate of processing.

●Can be used on the existing machine equipment for current machine tool equipment manufacturers.

●To conform the processing needs between traditional milling and ultrasonic.

HOLDING ELECTRIC CO., LTD.

Product Description :

Holding Magnetic tools honing edge machines can achieve the following effects in a short time.

1. Trim the chipped and sawn edges to remove burrs and burrs.

2. Achieving consistent rounding processing, making the blade smooth, smooth, and sharp, durable.

3. Improve the surface finish and surface roughness of the workpiece.

4. Increase tool life and reduce the probability of chipping. The measured value can increase the tool life by up to 65%.

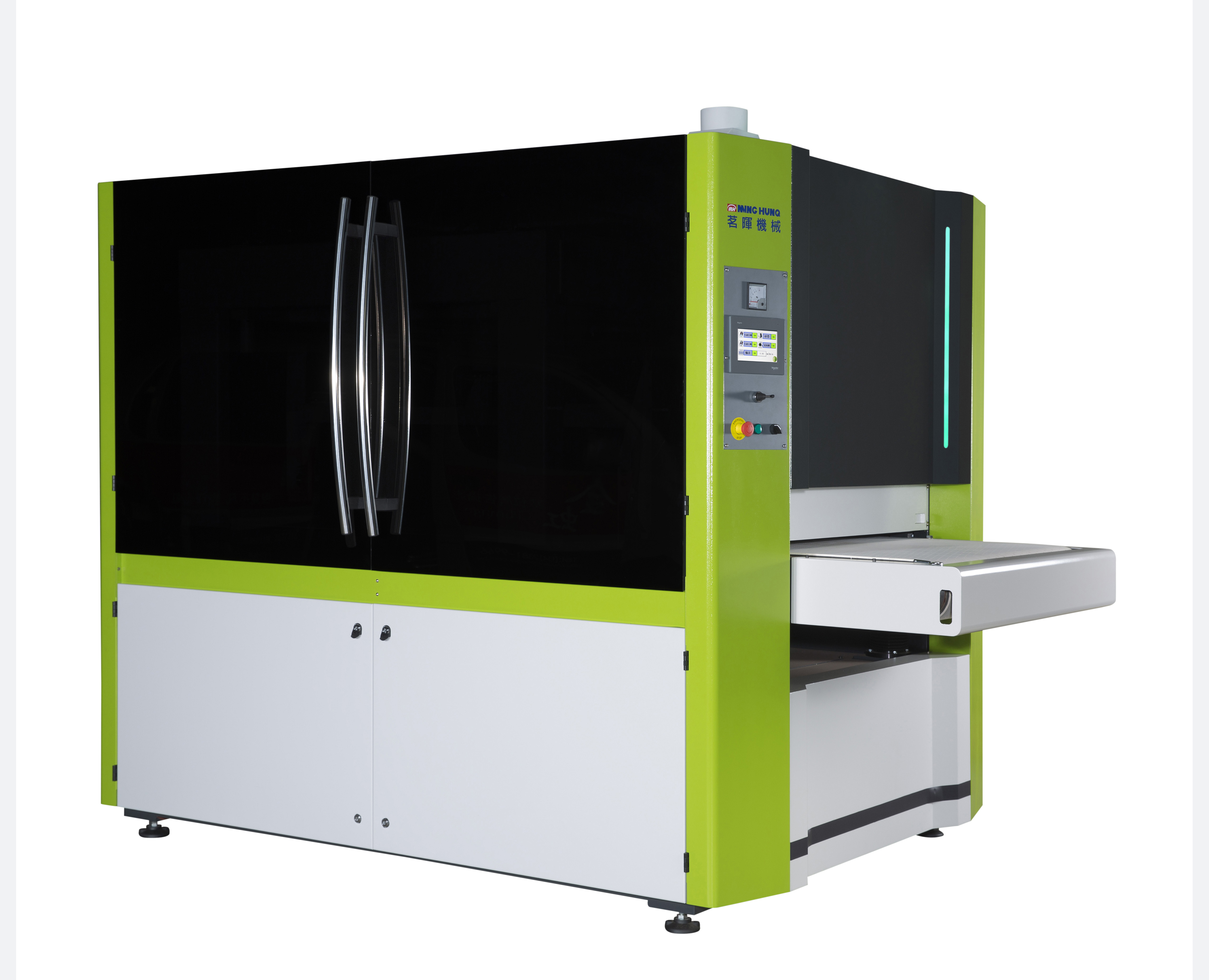

MING HUNQ MACHINERY CO., LTD.

Product Description :

GD-100 is a device that can serve your need for grinding and chamfering of sheet metal. Such as flame cutting, laser cutting, punching of the residue and bristles after stamping. All of the sharp angle of the edges and inner holes can easily be done on this machine.

YAW SHENG MACHINERY CO., LTD.

Product Description :

Yao Sheng Machinery Industrial Co. is committed to developing and manufacturing shot blasting machines. We have accumulated rich experience in the field over the four decades. This blasting machine equipped with rails, hangers and hooks, by special design-ensures an even shot blasting and satisfactory treatment in a shorter time. Widely applied in surface treatment in various industrial sectors includes casting, forging, die-casting parts, automobile parts and paint industry, etc.

We set up a R&D division and provide more varieties and customized machines to various industrial sectors. Manufacturing of all products is conformed to ISO standard, and we hold quite a few patents for the machine. Our product is high-functioning. This machine features the mechanism of rotation and spinning, by the special design can greatly reduces blasting time and cost. For all materials that require surface treatment.