Theme

Digital Transformation

Green Transformation

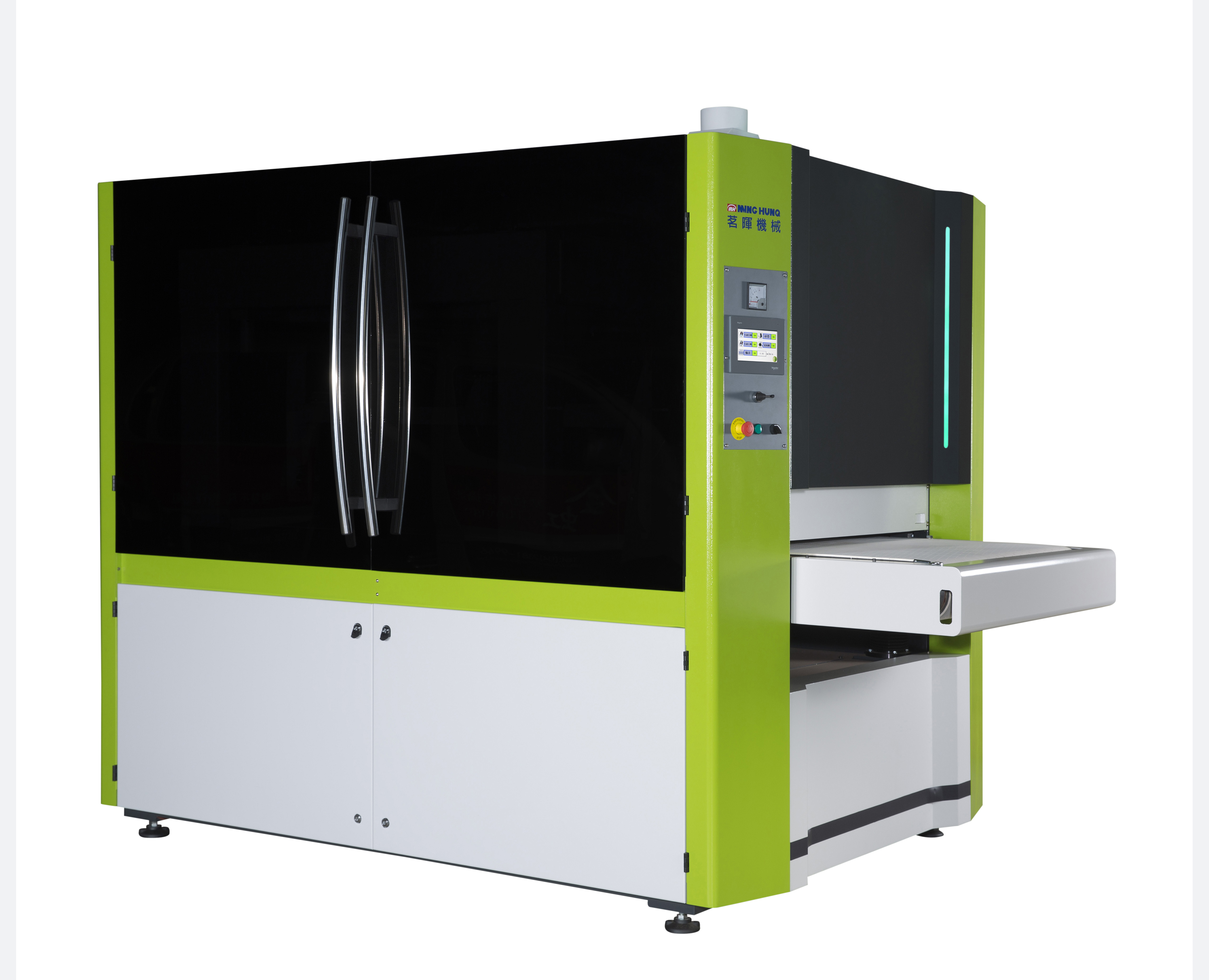

MING HUNQ MACHINERY CO., LTD.

Product Description :

GD-100 is a device that can serve your need for grinding and chamfering of sheet metal. Such as flame cutting, laser cutting, punching of the residue and bristles after stamping. All of the sharp angle of the edges and inner holes can easily be done on this machine.

YATAGHAN ENTERPRISE CO., LTD.

Product Description :

Miracle Air Grinders and Profiler-Linears have different types with high torque and excellent concentricity.

The variety of our tools can help you handle all processing conditions.

We provide all kinds of high quality Air Grinders and Profiler-Linears available on the market at competitive prices.

We provide all kinds of high quality Air Grinders and Profiler-Linears available on the market at competitive prices.

JAR HON MACHINERY CO., LTD.

Product Description :

1.Both cutting TAP and forming TAP are suitable.

2.Fully automatic tapping process. One operator can easily operate several machines at the same time.

3.By using proper master pitch gears(change gears A and B pair), highly accurate thread can be tapped. It is easy and quick to change different size.

4.The length of the tapping stroke can easily be adjusted for high accuracy which is suitable for tapping blind hole parts.

5.It has safe device to monitor the feeding, torque, radial, and clamping to keep TAP's long life and ensure safe working job.

6.It governed by PLC.

7.Long parts or those can't feed in vertical position are suitable.

8.Pre-work parts auto-checking and machine auto-stop if abnormal.

LEPAO ELECTRICITY MACHINERY CO., LTD.

Product Description :

Features

Double servo system, close-loop control , precision transmission, accurate in location

There are 6 combination of working coordinates in the system, it is convenient to design

programs and process workpiece

Showing location immediately, self-diagnostics and indicating error function

Providing with Start, Stop, manual fine-tuning, returning origin when it finished,

convenient to operate

Editing and modifying working program on controller

Chinese/ English switch , easy to operate

Supporting memory card, or USB to load files

The program can make by CAD/ CAM

Previewing route of working program

Control axis X , Y 6 axis maximum

Collocating with Pipe cutting, driller

8 inches LCD, a concise panel

Can install「Dust Collector 」

YATAGHAN ENTERPRISE CO., LTD.

Product Description :

36W/40W is lightweight Single Function Ultrasonic Polisher with affordable prices so it totally fits the requirements of endusers.

The high micro vibration stroke frequency saves time to reach a quality result of polishing and finishing.

Their shaking is much smaller than Air Tools and it is perfect for objects that needs detailed polishing. Like precision molds, electronic molds, PCB boards, jewelry and so on.

TSYR TZUN INDUSTRIAL CO., LTD.

Product Description :

PRODUCT FEATURES

FM-35DL Comes with drilling force control unit for Auto-feeding:

When drill bit is worn out, this unit will drive feeding intermittently or stop feeding. Once feeding becomes difficult while making a hole, please replace a new drill bit or re-sharpen the worn out one in order to protect both drilling tool and machine body from being damaged.

FM-35DL Comes with two intermittent breaking rates for breaking chips:

Choose different feeding rates according to different drill bits and material to perform Auto-feeding operation. This device can break chips intermittently and discharge them while Auto-feeding is processing, so that chips would not roll on drill bit.

Easier to discharge chips.

The machine body is with height adjustment. It’s suitable for both lone and short annular cutters as well as general chuck which is for holding drill with straight handle.

The general chuck is applicable for holding drill which is with straight handle for drilling smaller holes(from 8-13mm).

JAR HON MACHINERY CO., LTD.

Product Description :

1.Attached with multi head which can drill many parts at the same time in order to enhance efficiency.

2.Design a complete unit of multi head, guiding hole plate and jig in order to have high accuracy.

3.Suitable for reaming, drilling and chamfering.

4.Optional functions: "Auto. discharging chips" and "Auto. breaking chips".