Theme

Digital Transformation

Green Transformation

CHIAH CHYUN MACHINERY CO., LTD.

Product Description :

■No matter what operation – turning, milling, drilling, tapping, cutting, side turning and back machining, the

CB series does it all in one operation.

■Sliding head without a guide bush design provide faster setups, lesser remnants, and more cost reduction.

■The CB series provide multiple tooling systems is suitable for versatile cutting applications. On the front side

tooling system, user can set with 4+3 live tools, 6 O.D. tools and 5 I.D. tools. Moreover, on the back milling

system, user can set 4 live tools. The maximum tool speed is 6000 rpm. User can install O.D. and I.D. tools

on the back milling system.

■The sub-spindle head moves on the precision roller type linear ways with extra-large span design for

outstanding stability and positioning accuracy.

GPM CO.,LTD.

Product Description :

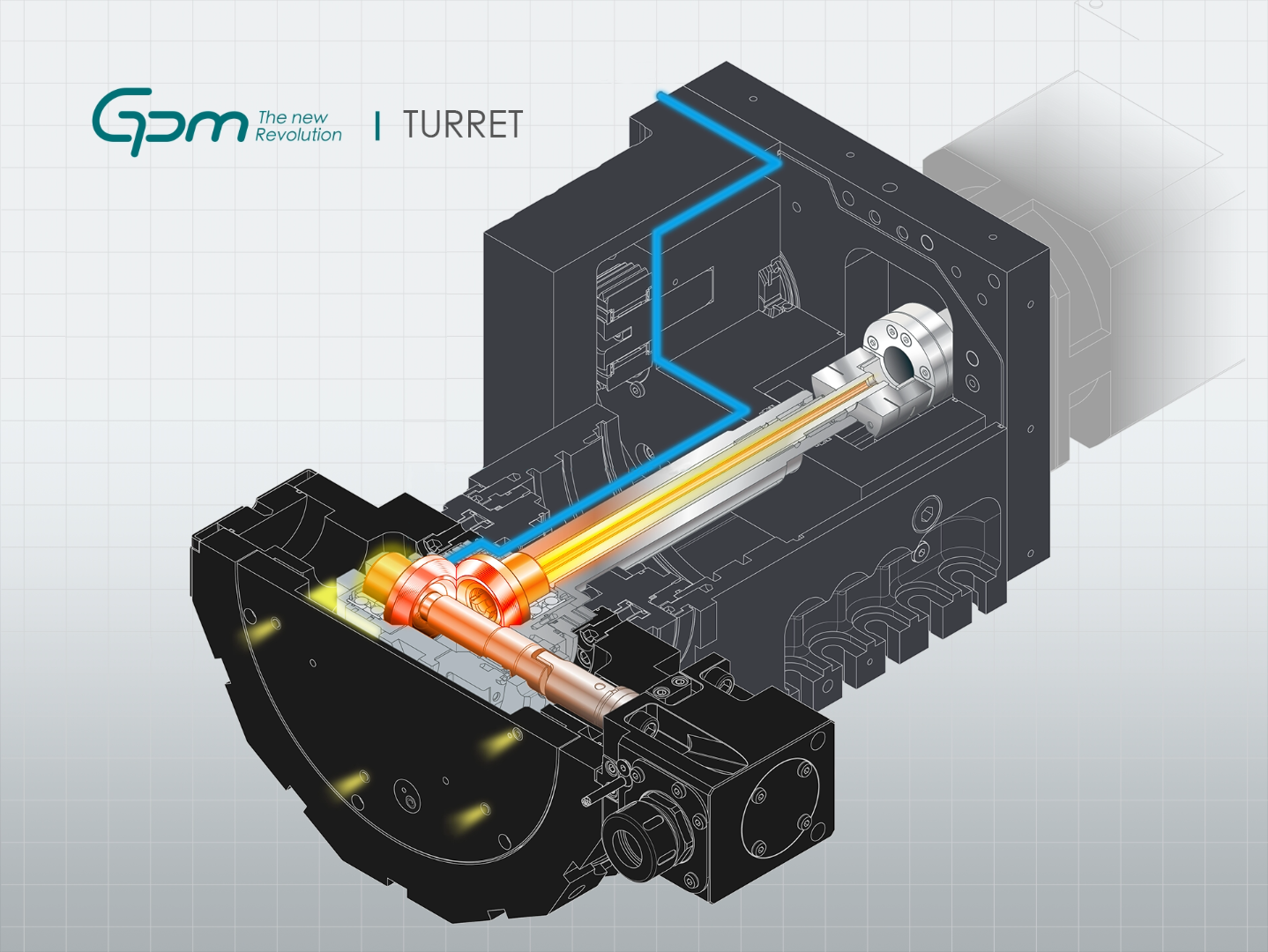

Product features :

■ High speed and long time operation & Reducing thermal deformation

● Tool drive speed <6000rpm; continuously operation allowed

● Tool drive speed at 8000rpm; continuous operation for 30mins, thermal displacement of tool disc <10µm, temperature <65°C

■ Increasing tool holder loading capacity

Battery free indexing motor (absolute type); no need to replace battery;

Tool holder loading capacity increase 100%

■ High pressure coolant : 25~150bar

■ PT-1000 high precision temperature sensor

JARNG YEONG ENTERPRISE CO., LTD.

Product Description :

1. External auto loading/unloading SPM

2. Its feeding capabilities are O.Dφ6~φ35 mm, max length 40mm.

3. Its feeding mechanism is placed outside of machine to keep mechanism from chips and oil stain.

4. Adjustable guideway is suitable for round/hex shape workpiece alone with rotary cylinder and fixture, which can make hex material positioning in short time.

JARNG YEONG ENTERPRISE CO., LTD.

Product Description :

1. High rigidity body structure, machine base casting is integrally formed and high rigidity linear guide way, providing stabler, faster and higher precision.

2. Built-in main spindle is with C-axis function, high speed, big power, high precision and low vibration which can make surface of workpiece smoother.

3. Optional:Synchronous rotary guide bushing device, it's suitable for processing long workpiece which can reduce cycle processing time and improve production efficiency.

4. Sub-spindle is with C-axis function, it can work with live tooling for end side drilling, tapping and milling.

5. It can depend on different demand of machining to with or without Synchronous rotary guide bushing device.

6. Axes:Z1/X1/Y/C1/Z2/X2/C2 + 3 sets of live tooling devices (A/B1/B2)

7. Max. 23 tools, can do machining on front side and back side at the same time which can save time for processing.

8. With guide bush type travel is 180mm, min. offal is 150mm. Without guide bush type travel is 310mm, min. offal is 50mm.

CHIAH CHYUN MACHINERY CO., LTD.

Product Description :

The WTS series combine with double turret, double spindle and double Y axis. Both of 16-station power turrets are available to be equipped of BMT-55 tooling system. The WTS has E-axis shifting function, it allows the sub spindle to move up and down to provide independent working area.

The WTS-52Y2M provide ∅51mm maximum bar feeding dia. and it can install fixed tailstock above the sub spindle when using collet, it allows to keep the longer workpiece dynamic balance with the main spindle and improves precision during machining. The WTS-65Y2M bar capacity up to ∅65mm, the A-6 spindle nose can install larger size chuck and the spindle motor upgrade to higher torque and bigger power.

MING YANG MACHINERY CO., LTD.

Product Description :

This multi-tasking turning center is an advanced machine designed for precision complex parts processed in one setup.

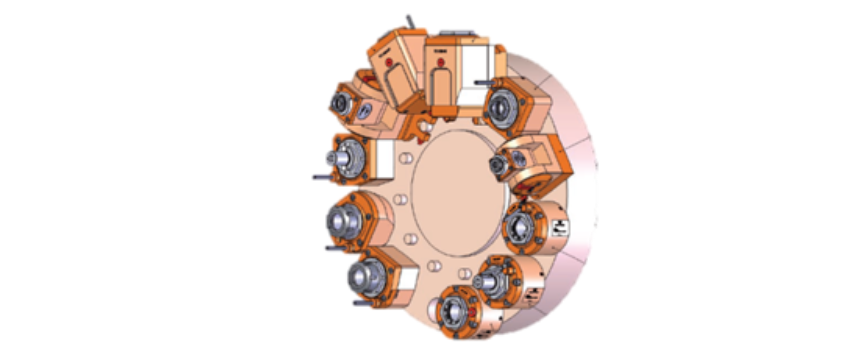

Power & Versatility: It has Double Spindles and Turrets with back machining provided by an 8-station sub-turret and sub-spindle with a total tool capacity of up to 32 tools. This solution is a powerful combination of power, precision and versatility.

Front Machining: BMT45 12-Stations, Up to 24 tools, 7.5/11 kW Spindle Power, 55 mm Through Hole.

Back Machining: VDI 25 8-Stations Sub-Turret, 3.7/5.5 kW Spindle Power, 48 mm Through Hole.

LIS AUTOMATIC CONTROLLED CO., LTD.

Product Description :

PJ-30MT is a fixed volume complex system. Controlled by the modular PCB board, provided the abnormal message notification of the system effectively. Suitable for using the fixed volume machines, such as CNC lathes, machine centers. This system integrates great advice from our countless loyal customers, and also LIS gain experiences in a broad of customers’ base developed a high-pressure coolant system for most industries when customers use the PJ system, it is more humane, easy to install, operate and maintain. Without a doubt, this is just a product of LIS which combine the suggestion from multiple parties.

SUN FIRM MACHINERY IND. CO., LTD.

Product Description :

The latest Sun Firm CST-46160 is a horizontal CNC precision lathe offering high flexibility and processing efficiency. Our specially designed spindle accommodates up to two sets of mandrels at the front and back, which is perfect for processing long tubes or bars. The turret is designed to fit the rigid platform-type rail structure, providing the best balance between high cutting resistance and processing efficiency. The design of the body structure is complete and the interface is taken into account in advance. It can support the robot arm, the automatic power system as well as the power turret and lead to a more efficient treatment, bringing us win-win benefits.

SUN FIRM MACHINERY IND. CO., LTD.

Product Description :

Machines are equipped with a product visualization. This remote monitoring system can check the life of machines' parts, spindle servo axis and tool. This device can report potential problems in advance and solve them, reducing cost and preventing waste of operational time.

Our specially designed spindle accommodates up to two sets of mandrels at the front and back, which is perfect for processing long tubes or bars. The turret is designed to fit the rigid platform-type rail structure, providing the best balance between high cutting resistance and processing efficiency. The design of the body structure is complete and the interface is taken into account in advance. It can support the robot arm, the automatic power system as well as the power turret and lead to a more efficient treatment, bringing us win-win benefits.