Theme

Digital Transformation

Green Transformation

LEADWELL CNC MACHINES MFG., CORP.

Product Description :

Twin spindle & twin turret design, it can turn the different parts on the spindle and identical parts on both spindles at the same time. Integrated with 3-axis robot arms, to reach different OP and automation requested. Considering the turning efficiency, with automation high-speed robot reduces the loading/unloading time, with a high rigidity stricture design to increase the stability. On the other hand, the multiple types of robot arms will be able to satisfy the different demands of the client.

Max. swing: 290mm

Max. turning diameter: 290mm

Max. turning length: 220mm

X-axis travel: 195+5mm

Z-axis travel: 300mm

Spindle speed: 3500rpm

Spindle nose: A2-6

Chuck size: 10"

Spindle motor power: 11/15kw

Number of tool stations: 12T

SUN FIRM MACHINERY IND. CO., LTD.

Product Description :

Machines are equipped with a product visualization. This remote monitoring system can check the life of machines' parts, spindle servo axis and tool. This device can report potential problems in advance and solve them, reducing cost and preventing waste of operational time.

Our specially designed spindle accommodates up to two sets of mandrels at the front and back, which is perfect for processing long tubes or bars. The turret is designed to fit the rigid platform-type rail structure, providing the best balance between high cutting resistance and processing efficiency. The design of the body structure is complete and the interface is taken into account in advance. It can support the robot arm, the automatic power system as well as the power turret and lead to a more efficient treatment, bringing us win-win benefits.

TONGTAI MACHINE & TOOL CO., LTD.

Product Description :

‧Dual-spindle, dual-turret CNC lathe with an integrated loading/unloading robotic arm.

‧Designed for processes that require automatic single-piece feeding.

‧The MT series features a smaller footprint, shorter automation pathways, and higher productivity.

‧Short travel distances, minimal idle time, and minimal thermal displacement.

‧The TiOperator enables the MT series to achieve efficient 24-hour operation effortlessly.

MING YANG MACHINERY CO., LTD.

Product Description :

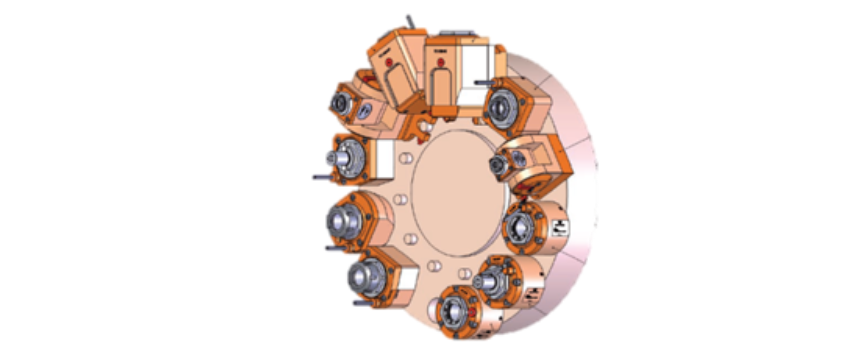

This multi-tasking turning center is an advanced machine designed for precision complex parts processed in one setup.

Power & Versatility: It has Double Spindles and Turrets with back machining provided by an 8-station sub-turret and sub-spindle with a total tool capacity of up to 32 tools. This solution is a powerful combination of power, precision and versatility.

Front Machining: BMT45 12-Stations, Up to 24 tools, 7.5/11 kW Spindle Power, 55 mm Through Hole.

Back Machining: VDI 25 8-Stations Sub-Turret, 3.7/5.5 kW Spindle Power, 48 mm Through Hole.

L & L MACHINERY INDUSTRY CO., LTD.

Product Description :

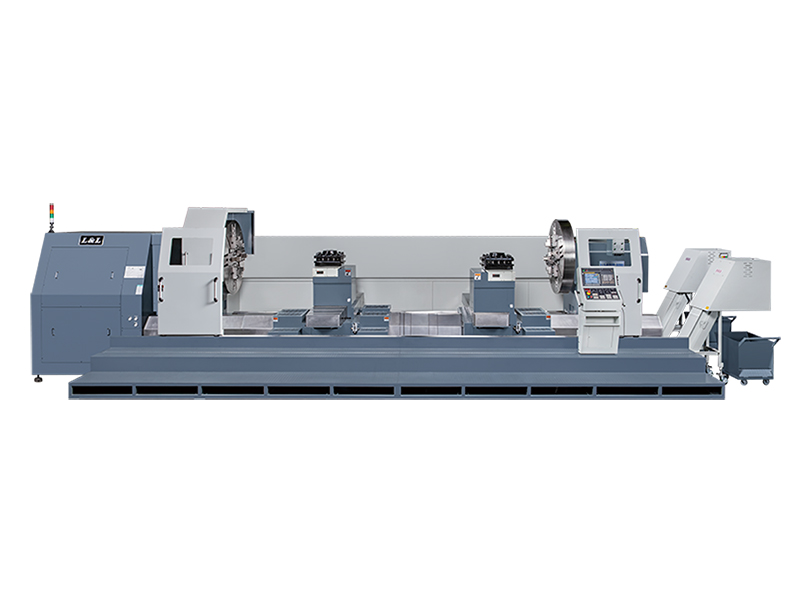

Smart heavy-duty multi-axis composite cutting machine, LLS-M, for the target industry market (oil industry, aerospace industry, steel industry and rubber and rubber industry), achieved ALL Processes In One Machine to reduce the clamping and shortening process, with precision and life management The intelligent machine, constructing the machine information management platform and man-machine management interface, integrating the computer numerical controller, the smart set-top box and the cloud product life cycle database, providing relevant data and data through artificial intelligence calculation analysis and application, reaching the machine Accuracy and life and performance improvement, and applied to the virtual reality pre-sales service system, the use of the real-life expansion after-sales service system to build a smart mechanical value service chain.

JARNG YEONG ENTERPRISE CO., LTD.

Product Description :

1. This model combined the functions of turning and milling and can provide customers with more working conditions.

2. Optional C-axis for arbitrary angle spindle positioning and contour control

3. Optional Y-axis live tooling device and end live tooling device can be used for inner and outer diameter turning and milling.

4. Optional:Y-axis side milling device (4-shaft, ER-20), and the distance between each shaft reaches 55mm.

FUI JET TECH CO., LTD

Product Description :

The zero-point positioning system is a normal clamping mechanism, which is opened during ventilation and the air pressure is cut off. When the zero-point positioning system is ventilated, the pressure will pass through the compressed spring inside the piston, causing the piston to rise, and the steel balls can retreat toward the water pump. When the air source is turned off, the spring will push back the piston, and the piston handle will The steel ball is pushed toward the middle, causing the ladder bolt to

OWNNER INDUSTRIAL CO., LTD.

Product Description :

Standard Gang-type or Turret(optional). Gang-type permits quick tool change. Gang-type tool system can make tools change faster. Increase the external oil tank and lengthen the oil temperature cooling time.The oil temperature natural cooling principle is adopted to make the processing oil temperature more stable.

OWNNER INDUSTRIAL CO., LTD.

Product Description :

Standard Gang-type or Turret(optional). Gang-type permits quick tool change. Gang-type tool system can make tools change faster. Increase the external oil tank and lengthen the oil temperature cooling time.The oil temperature natural cooling principle is adopted to make the processing oil temperature more stable.