Theme

Digital Transformation

Green Transformation

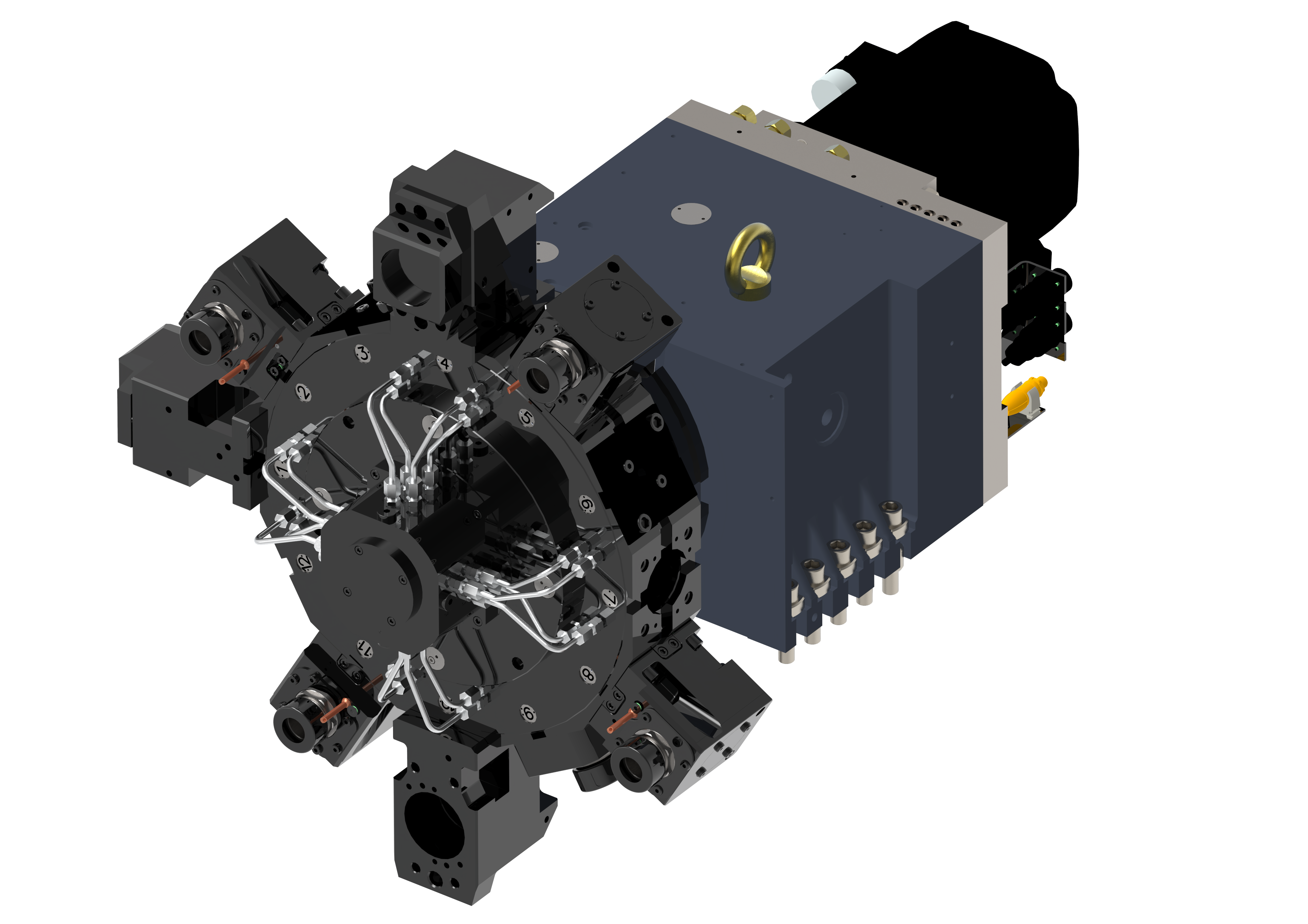

GPM CO.,LTD.

Product Description :

Tool holder equipped with Capto automatic clamping unit- Achieving auto tool change by hydraulic clamp & unclamp.

Embedded 5 channels for hydraulic clamp, unclamp, coolant, air blast and probe contact. Clamping units may be mounted radially or axially to satisfy the uniqueness of each machine. Contact with us for any customized designs.

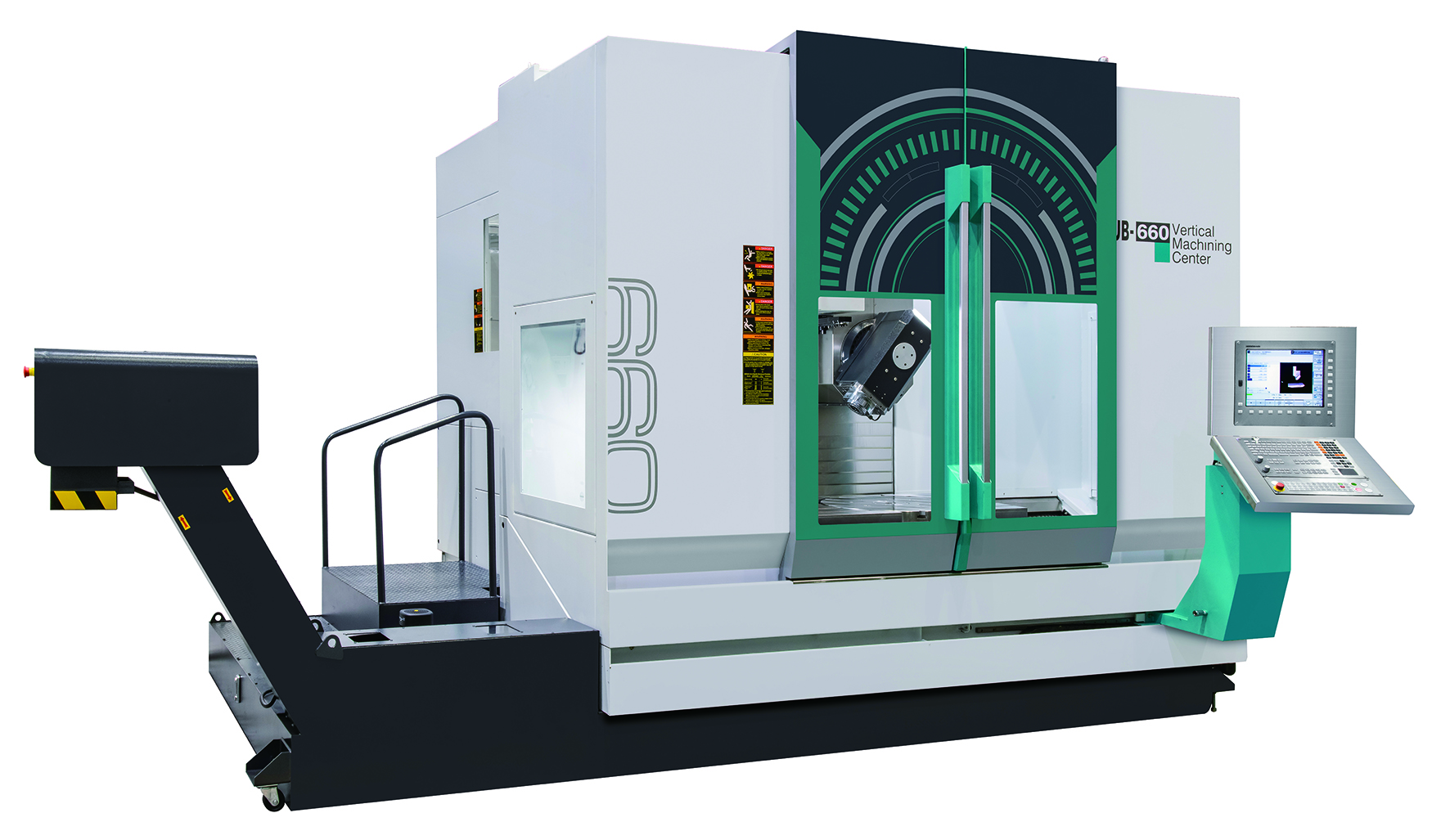

FAIR FRIEND ENTERPRISE CO., LTD.

Product Description :

★Moving column structure :

The M-shaped structure increases anti bend and anti-torsion of the column The counter-weight is supported by the pneumatic cylinder. The shape of the column is similar to the pyramid to increase the stability for moving.

★One piece base structure :

The rigidity of structure is good. The outer shape is not complicated, it is easy for machining. The internal structure adopts the box type design to increase the bearing capacity.The round shape hole is easy to clear sand and increase force flow. The work tableadopts the high and low rail design to increase the rigidity.

★Rotary spindle head structure:

Reduce the interference machining area.

★Modular design :

By changing the column head of the column, etc., the customer can have a variety of opportunities to choose from.

★Turning and milling function(OPT)

Shorten the product manufacturing process. To improve the production efficiency, accuracy and reduce the clamping times and floor space. It can be used in aerospace parts and medical equipment precision molds.

QUASER MACHINE TOOLS, INC.

Product Description :

MF700’s design concept is to strengthen Column-moving C frame structure, and separate linear & rotary axes, optimize it with FEMA analyze, the advantages are high rigidity in structure, high precision in machining, and operator friendly. To separate linear & rotary axes is to minimize the following errors and ensure machining accuracy, on top of that, the transmission mechanism/components is away from working area which can reduced parts failure from pollution of coolant and chips.

The linear axes has a cross-frame design, the wide-span column and large-size linear way blocks provides excellent stability during high-speed cutting. Rotary table is intergraded with bridge type column, this compact design can bring us smaller footprint and maximize working envelope.

Rotary table with tailstock support can increase the load capacity which is capable up to 500kg, maximum swing for workpiece is 700mm and height is up to 500mm.

The standard worm gear/wheel and encircling brake design provide high rigidity and lock-force. For different application like high speed demand in aerospace, it can be upgraded with dual Direct Drive Motor.

Operator friendly design with 2 wide open doors are not only easier for operator but also easier for automation upgrade. More thoughtful is we offer three different types of top guards for different work environment, telescope type, solid top cover and open top.

New base design allow chips fall onto conveyor directly, reduce 50% your chip cleaning time.

YEONG CHIN MACHINERY INDUSTRIES CO., LTD.

Product Description :

NFX400A is designed especially for small, complex high-quality parts mainly for aerospace, automotive, medical, job shop and die & mold applications

■ Extra wide column and base design to ensure best support and cutting rigidity.

■ Increased tool life by cutting with belly and edge of the tool

■ Reduce fixture error and improve workpiece loading and uploading time

■ Greatly reduced non-cutting or setup waiting time

■ Saves manufacturing cost with reduced fixture and electrode costs.

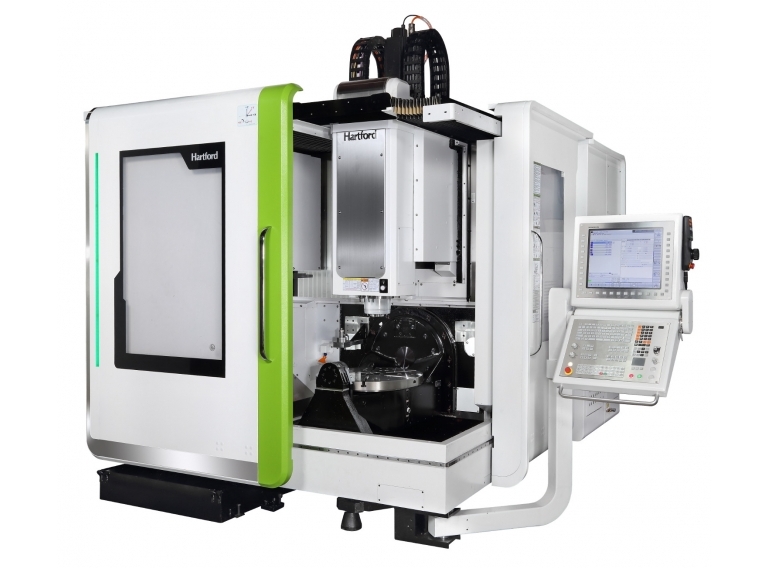

MANFORD MACHINERY CO., LTD.

Product Description :

VX-600 5-Axis Machining Center is designed for multiaxes machining of small and large series of complex 5-side workpieces. With swiveling head and rotary table, VX-series is able to do simultaneous 5 axes machining with high accuracy.

High proformance swiveling head, tilting angle from -120 ~ +30 equipped with 15,000rpm built-in spindle.

VX-600/VX-600T is with an enbedded Ø 630mm diameter rotary table. Any complex workpiece can be accomplished with a single setup.

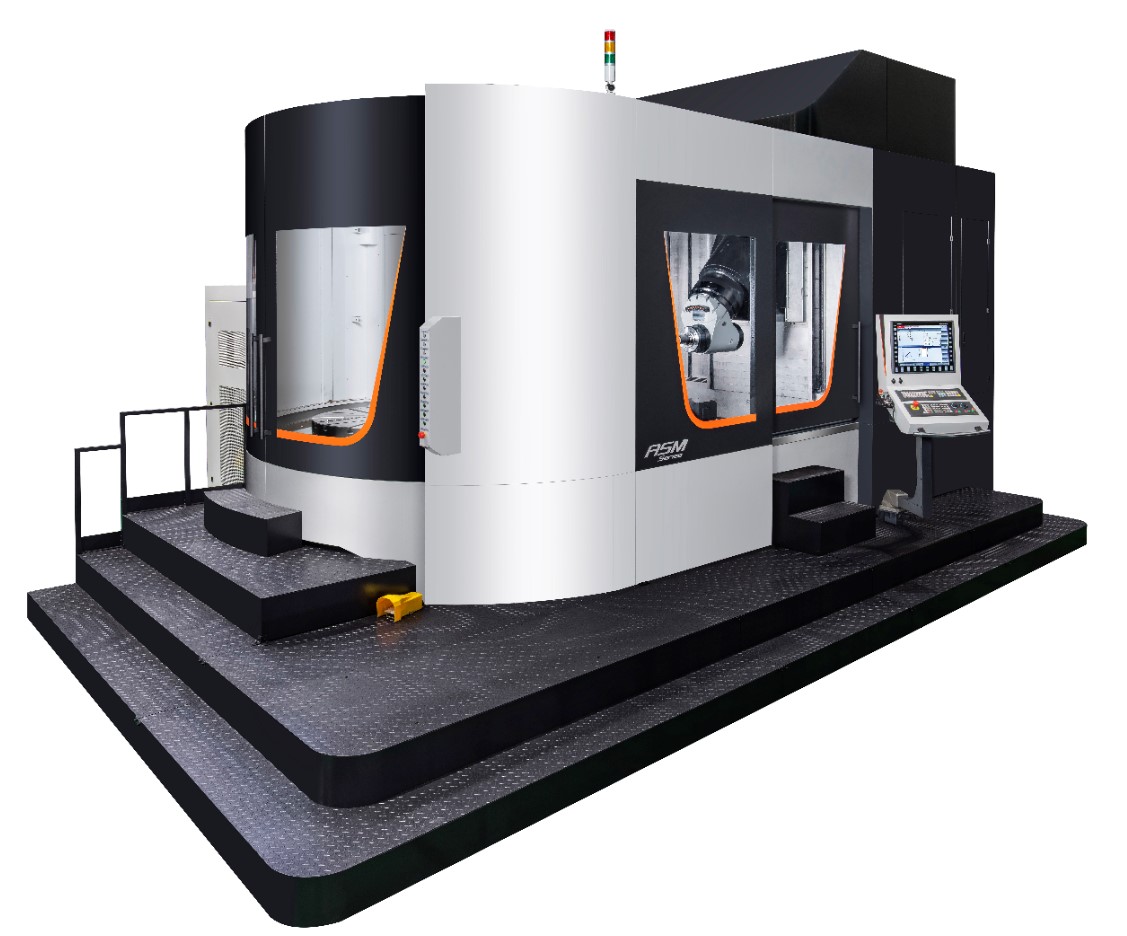

VISION WIDE TECH CO., LTD.

Product Description :

• ASM is the first 5-axis CNC turning and milling machining center of Vision Wide, and it is particularly designed for delicate cylindrical components machining featuring high acceleration, rapid feed-rate and synchronized axes machining, especially for aerospace components, tire molds, turbine blades and aluminum parts.

ASM accessorizes with 5-axis universal head and rotary shafts built-in D.D motor. Through topology analysis, ASM realizes the best distance between tool center point and B-axis transmission

• Positioning P0.006mm

• Repeatability Ps0.0055mm

• Spindle thermal compensation 0.02 mm

• Rapid Traverse 40m/min

• Acceleration 0.3G

• Cutting Feed rate 24 m/min

QUASER MACHINE TOOLS, INC.

Product Description :

This single unit machine features high rigidity, accuracy, and efficiency and offers a high ease of operation with a relatively compact footprint.

The Symmetrical design ensures the rigidity of the machine tool, which results in better damping performance and lower thermal displacement.

The modular design allows for expandable multi-pallet configurations.

REN AN INFORMATION TECHNOLOGY CO., LTD.

Product Description :

Just like the real CNC machine, equipped with exactly same overall appearance, actual handwheel and real machine operation panel as numerical control machine.

Solving the difficulties of real machine: precise, complicated and very expensive.

With CNC Simulator, everyone can learn CNC machine operation and accumulate hands-on operation skills.

CNC training machine is equipped with exactly same overall appearance, actual handwheel and real machine

operation panel as numerical control machine. Its purpose is to train students for accumulating CNC machine operation skills (program transmission, programming, tool selection, tool compensation and alarm clear )

Overall design is more attractive, and it emphasizes on interaction to make students less mistakes happened.

Not only decreasing learning cost but also letting students work and learn in the safe environment.

FAIR FRIEND ENTERPRISE CO., LTD.

Product Description :

★Optimized structure configuration

- The base and column are structured as one-Piece casting, which eliminates possible tolerance of the jointing interface.

- Box-opstructure casting and optimal span realize exceptional rigidity and stability.

★Overlapped Axes with 2 Rotating Axes

- Axes of linear movement and rotation are separated so that during 5-axis machining, curve tolerance or error can be controlled and adjusted rather easily.

★3 Axes Motion Area Partitioned Processing Area

- Effective In addition to space chips removal, promoting Antifouling capability, optimal span realize exceptional rigidity and stability.

★Chip removal function

- Forming one large funnel chips off, high performance chip removal