Theme

Digital Transformation

Green Transformation

HUNG CHIH LIMITED COMPANY

Product Description :

GROB’s products range from general machining centers to highly flexible automated production systems, from machining assembly units to fully automated assembly lines. Furthermore, motor production and assembly equipments for battery and fuel cell technology are also included in the product range. GROB has thermal spray technology suitable for engine components and can provide customized solutions for the processing of turbine casings, frame structure workpieces, chassis workpieces and battery casings.

Under the framework of Industry 4.0, GROB has taken an important step and launched the GROB-NET4Industry software for future-oriented digital and networked production. GROB has also successfully entered the field of additive manufacturing and developed a new liquid metal printing equipment.

FAIR FRIEND ENTERPRISE CO., LTD.

Product Description :

★Optimized structure configuration

- The base and column are structured as one-Piece casting, which eliminates possible tolerance of the jointing interface.

- Box-opstructure casting and optimal span realize exceptional rigidity and stability.

★Overlapped Axes with 2 Rotating Axes

- Axes of linear movement and rotation are separated so that during 5-axis machining, curve tolerance or error can be controlled and adjusted rather easily.

★3 Axes Motion Area Partitioned Processing Area

- Effective In addition to space chips removal, promoting Antifouling capability, optimal span realize exceptional rigidity and stability.

★Chip removal function

- Forming one large funnel chips off, high performance chip removal

REN AN INFORMATION TECHNOLOGY CO., LTD.

Product Description :

Just like the real CNC machine, equipped with exactly same overall appearance, actual handwheel and real machine operation panel as numerical control machine.

Solving the difficulties of real machine: precise, complicated and very expensive.

With CNC Simulator, everyone can learn CNC machine operation and accumulate hands-on operation skills.

CNC training machine is equipped with exactly same overall appearance, actual handwheel and real machine

operation panel as numerical control machine. Its purpose is to train students for accumulating CNC machine operation skills (program transmission, programming, tool selection, tool compensation and alarm clear )

Overall design is more attractive, and it emphasizes on interaction to make students less mistakes happened.

Not only decreasing learning cost but also letting students work and learn in the safe environment.

YEONG CHIN MACHINERY INDUSTRIES CO., LTD.

Product Description :

Most Popular High Performance NSV106AS is well suited for superior surface finishing works, specially in automotive, job shop and electronics industries. ■ Large delta machine column and base ensure the highest stability during high speed movement■ High precision roller type guideways on all 3 axes■ High precision linear guideway with 6 slide blocks on X-axis■ High performance YCM in-house designed spindle with low vibration to achieve excellent finish

CAMPRO PRECISION MACHINERY CO., LTD.

Product Description :

CAMPRO develops a proprietary system combined with precision tooling/material cabinet to assist customers in managing and analyzing tooling/material usage, 24 hours to get tools or materials and early-warning or alert notifications. The T Series are focus on cutters which is able to adjust the width according to different cutter such as milling, drilling, end-mill, tapping and so on. The patented transmission system allows user to select and dispense, withdraw cutters easily. Available to augment cabinets, max. support 100 cabinets. (Disc Type Cabinet, Tools Holders Cabinet, Recycling Cabinet, Compartment Type Cabinet, and Drawer Type Cabinet)

KAO FONG MACHINERY CO., LTD.

Product Description :

5-axis synchronous machining of the KMU series can be used for multi-faceted processing of workpiece clamping positioning at one time or processing deep hole mold and inverted hook area.

Three-axis structure using box-type construction design, which can effectively improve the rigidity of the machine.

X / Y / Z axis with high rigidity roller type linear guideway, with high rigidity, fast moving, low wear and other characteristics, which can greatly enhance the processing dynamic precision and stability and effectively increase production efficiency.

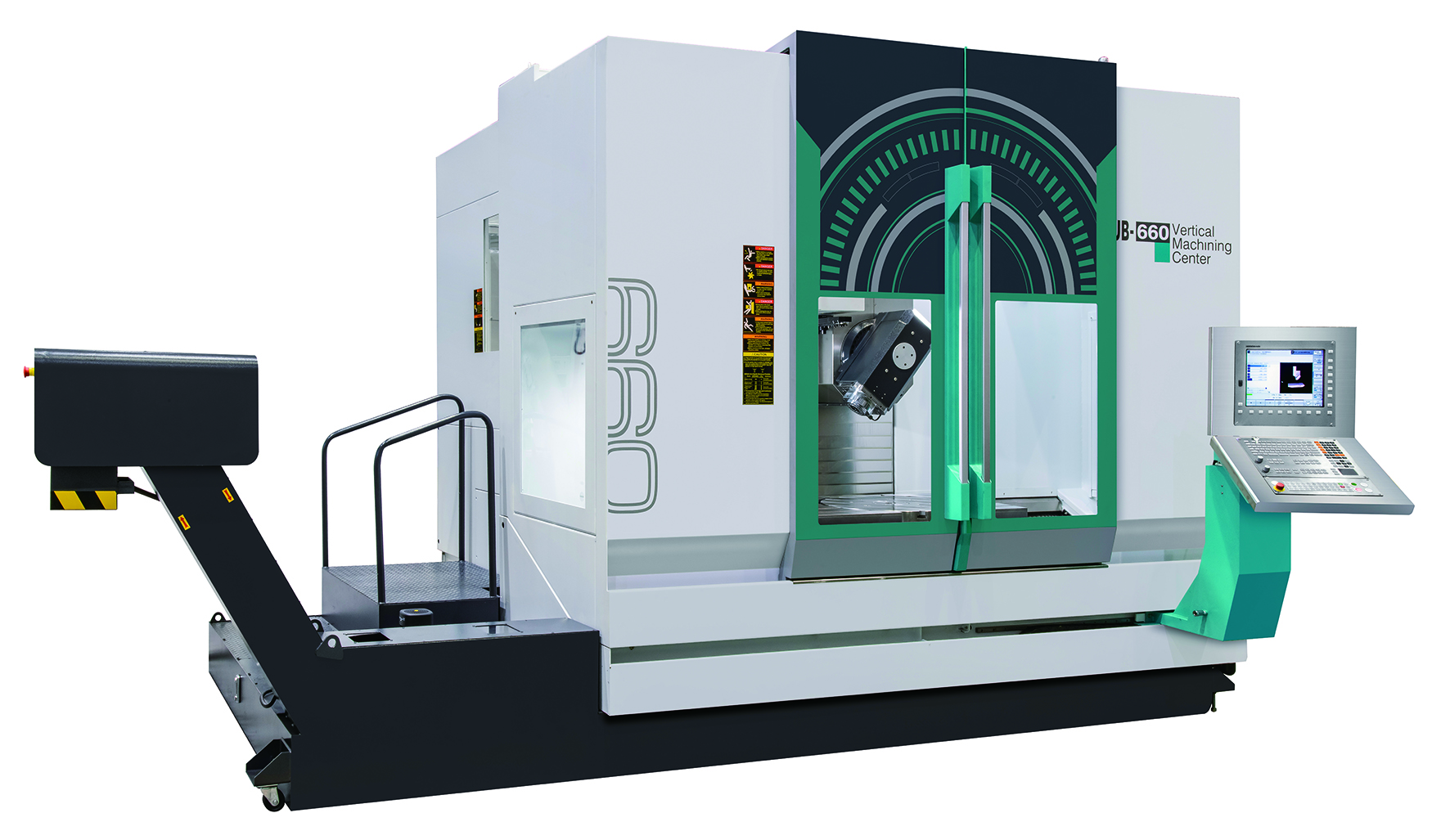

MANFORD MACHINERY CO., LTD.

Product Description :

VX-600 5-Axis Machining Center is designed for multiaxes machining of small and large series of complex 5-side workpieces. With swiveling head and rotary table, VX-series is able to do simultaneous 5 axes machining with high accuracy.

High proformance swiveling head, tilting angle from -120 ~ +30 equipped with 15,000rpm built-in spindle.

VX-600/VX-600T is with an enbedded Ø 630mm diameter rotary table. Any complex workpiece can be accomplished with a single setup.

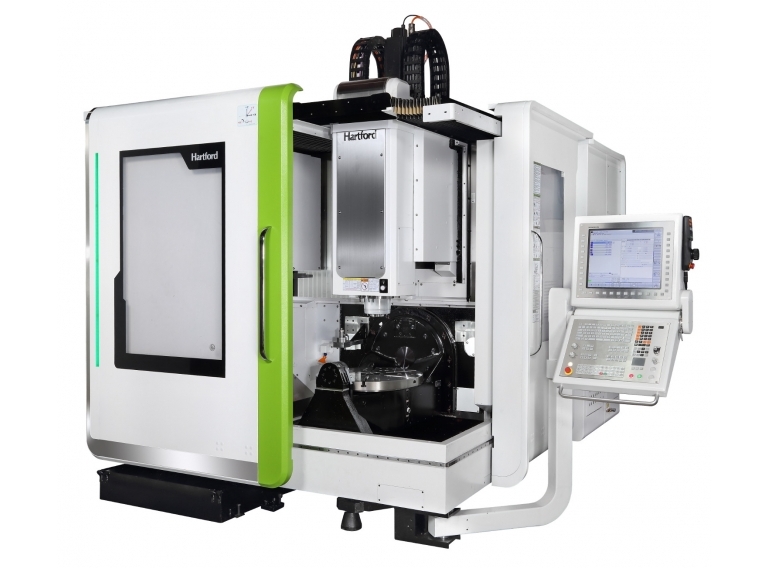

FAIR FRIEND ENTERPRISE CO., LTD.

Product Description :

★Moving column structure :

The M-shaped structure increases anti bend and anti-torsion of the column The counter-weight is supported by the pneumatic cylinder. The shape of the column is similar to the pyramid to increase the stability for moving.

★One piece base structure :

The rigidity of structure is good. The outer shape is not complicated, it is easy for machining. The internal structure adopts the box type design to increase the bearing capacity.The round shape hole is easy to clear sand and increase force flow. The work tableadopts the high and low rail design to increase the rigidity.

★Rotary spindle head structure:

Reduce the interference machining area.

★Modular design :

By changing the column head of the column, etc., the customer can have a variety of opportunities to choose from.

★Turning and milling function(OPT)

Shorten the product manufacturing process. To improve the production efficiency, accuracy and reduce the clamping times and floor space. It can be used in aerospace parts and medical equipment precision molds.

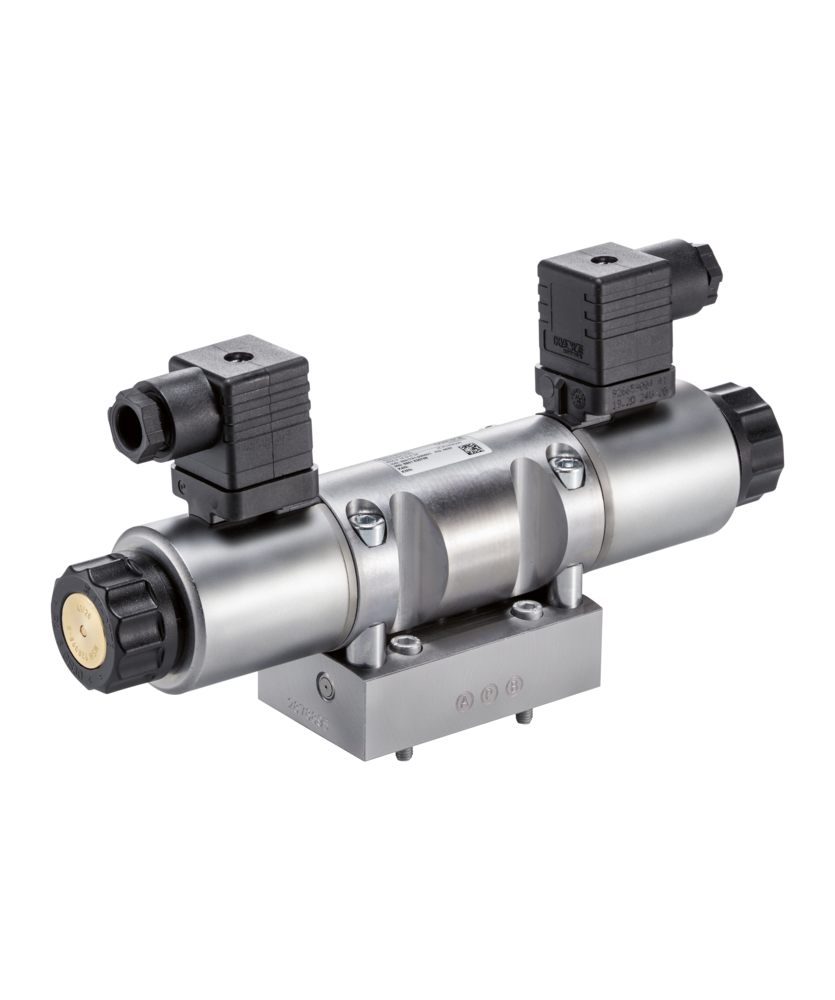

HAWE Hydraulik Singapore Pte. Ltd. Taiwan Branch

Product Description :

Directional seated valves are a type of directional valve. As cone valves they are tightly sealed, with zero leakage in the closed state.

The directional seated valve type ROLV is available as a 3/2, 4/2 or 4/3-way directional seated valve with different plug types. The patented assembly consists of two parts: a round basic valve with the valve inserts, and an adapter plate which can be designed for manifold mounting with nominal size NG 6 as the

standard connection pattern, or for direct pipe connection.

Additional elements such as a check valve, a restrictor (on the consumer side) and/ or restrictor check valves can be integrated, depending on the functional requirement and adapter plate. The type ROLV can be combined in the valve bank type BA with other types of valves.

Features and benefits

■ Dirt-resistant design with high switching reliability

■ Interchangeable solenoid for greater flexibility and easy servicing

Intended applications

■ Machine tools (cutting and non-cutting)

■ Clamping tools, punching tools, fixtures

■ Testing machinery

■ Wind turbines