Theme

Digital Transformation

Green Transformation

HAWE Hydraulik Singapore Pte. Ltd. Taiwan Branch

Product Description :

Compact hydraulic power packs are a type of hydraulic power pack. They arecharacterised by a highly compact design, since the motor shaft of the electric drive also acts as the pump shaft. Compact hydraulic power packs are designed to supply hydraulic circuits with hydraulic fluid.

The compact hydraulic power pack type INKA consists of the tank, the integrated motor and the radial piston pump or gear pump directly attached to the motor

shaft. The directly mounted electronic communication box with integrated realtime operating system allows the operating state to be recorded and visualised. The

measured values of the integrated multi-sensor (including the motor speed) can be passed on to the higher-level machine controls via standardised interfaces and processed there.

The consistently modular design of the type INKA means that different usage volumes and delivery flows can be realised quickly and easily from the modular

system. Compatible, ready-for-connection, complete solutions can be assembled easily using a wide range of connection blocks and the valve banks that can be combined with them.

Features and benefits

■ Prepared for condition monitoring with integrated sensors and communication box

■ Optimum efficiency through under-oil motor cooling, direct power transmission,and sophisticated heat dissipation

■ Suitable for nominal operating modes S2 (short period operation) and S3 (periodic intermittent operation)

■ Resource-saving due to small oil filling volume

Intended applications

■ Machine tools and material testing

■ Hydraulic tools

■ Handling systems

■ Presses and processing machines

HC FENG CO., LTD.

Product Description :

Replenishing Fluid automatically, accurate cutting fluid concentration. One equipment to multiple CNC machining centers. The supply line can be as long as 20 meters.

#Filtration by 3 filters #Sterilization by ozone # Oil-water mixer to precise mixing 0-10% cutting fluid #Stirring device avoid cutting fluid become stagnant water. #oil tank level meter for 50 gallon barrel low level detection.

HUNG CHIH LIMITED COMPANY

Product Description :

GROB’s products range from general machining centers to highly flexible automated production systems, from machining assembly units to fully automated assembly lines. Furthermore, motor production and assembly equipments for battery and fuel cell technology are also included in the product range. GROB has thermal spray technology suitable for engine components and can provide customized solutions for the processing of turbine casings, frame structure workpieces, chassis workpieces and battery casings.

Under the framework of Industry 4.0, GROB has taken an important step and launched the GROB-NET4Industry software for future-oriented digital and networked production. GROB has also successfully entered the field of additive manufacturing and developed a new liquid metal printing equipment.

HC FENG CO., LTD.

Product Description :

The combination of centrifugal device and magnetic separator is perfect for processing water-and oil-based cutting fluids and sludge containing magnetic dusts and shavings. The shaving removal is quick and effective, which saves a lot of time waiting and minimizes the costs to replace consumables.

HC FENG CO., LTD.

Product Description :

4 in 1 Coolant Purification System

1. Filtering floating debris and dirty particles

2. Oil/Water Separation, removes tramp oil down to 5% water content

3. Ozone Disinfection, eliminates bacteria and cleaned fluid backflow

4. Automatic control panel and pH detect device

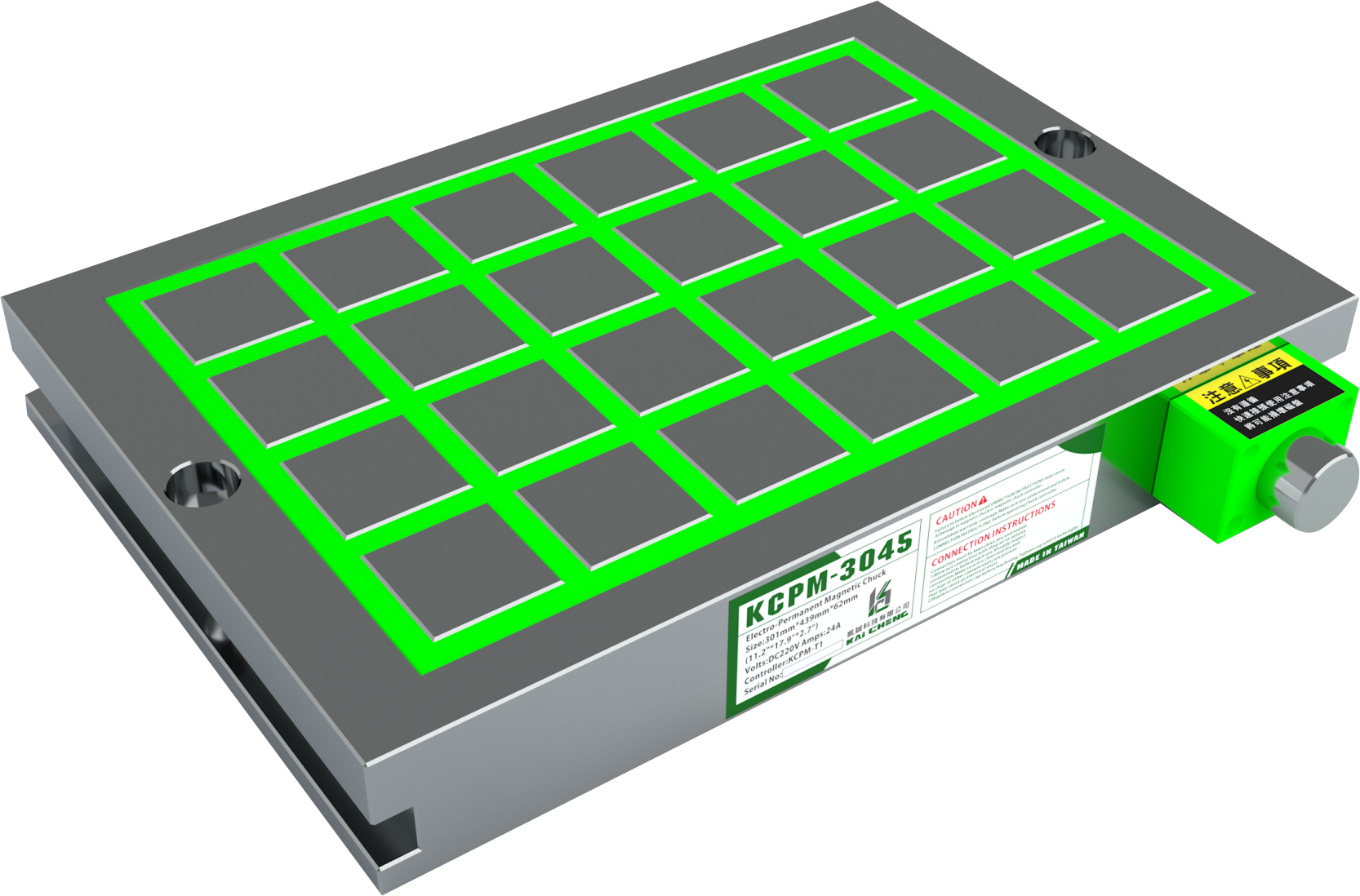

kai cheng co.,ltd

Product Description :

Features of the electro-permanent magnetic chuck:

1.Strong magnetic power, as high as 1300kgf/110mm2 ±5%. (4 magnetic poles)

2.Electro-permanent magnetic design; 1-2 seconds to magnetize/demagnetize, does not require constant power supply during usage, no temperature rise, fit for long-term use, precision will not be affected by deformations to the workpiece from rising temperatures.

3.Use in coordination with the soft magnetic clamp, the tools will be able to move freely when machining, five-sides machining, drilling, tapping, groove milling, molding can be completed all at once, which significantly increases work efficiency and reduces the repeated position tolerance to achieve the precision requirement.

4.Shortens the workpiece placement time, the clamping area can evenly cover the complete machining range, able to work on multiple workpieces at the same time, improves machining processing time.

5.Can carry out five-sides machining.

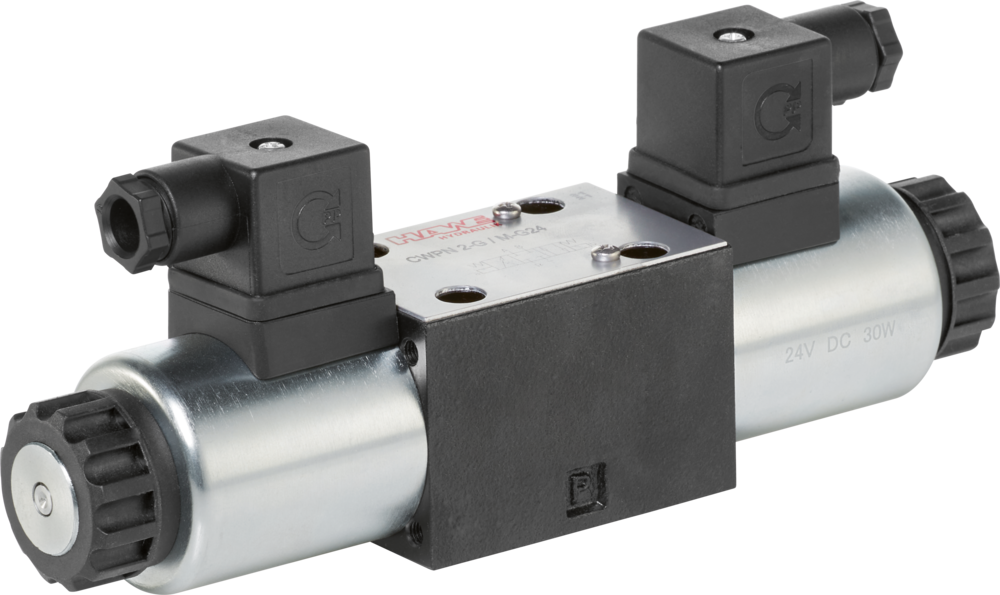

HAWE Hydraulik Singapore Pte. Ltd. Taiwan Branch

Product Description :

Directional spool valves are a type of directional valve. They control the direction of

movement and the velocity of single and double-acting hydraulic consumers.

The directional spool valve type CWPN is a 4/3- or 4/2-way directional valve with standard connection pattern NG 6 (CETOP 03). It is directly actuated and a binary

valve.

The directional spool valve type CWPN can be flexibly combined with the common HAWE valve banks and compact hydraulic power packs. It can also be mounted on customer-specific manifolds or sub-plates.

Features and benefits

■ Universally usable thanks to standard connection pattern NG 6 (CETOP 3) according to ISO 4401-03 or DIN 24 340-A6

■ Modular system with various circuit symbols and actuation variants

■ Optionally also available with additional valves in port P

Intended applications

■ Machine tools

■ Wind turbines

■ Solar power plants

■ Industrial hydraulics