Theme

Digital Transformation

Green Transformation

NUMEN MACHINERY CO., LTD.

Product Description :

*High-rigidity structure design, using C3 precision ball

screw for axial feed and direct drive with servo motor.

* X/Y/Z axes installed with roller type of linear slide way

to ensure rigidity of axial movement and fast feed rate.

* Direct drive spindle.

* Suitable for various processing industries.

* 4th axis / 5th axis applications.

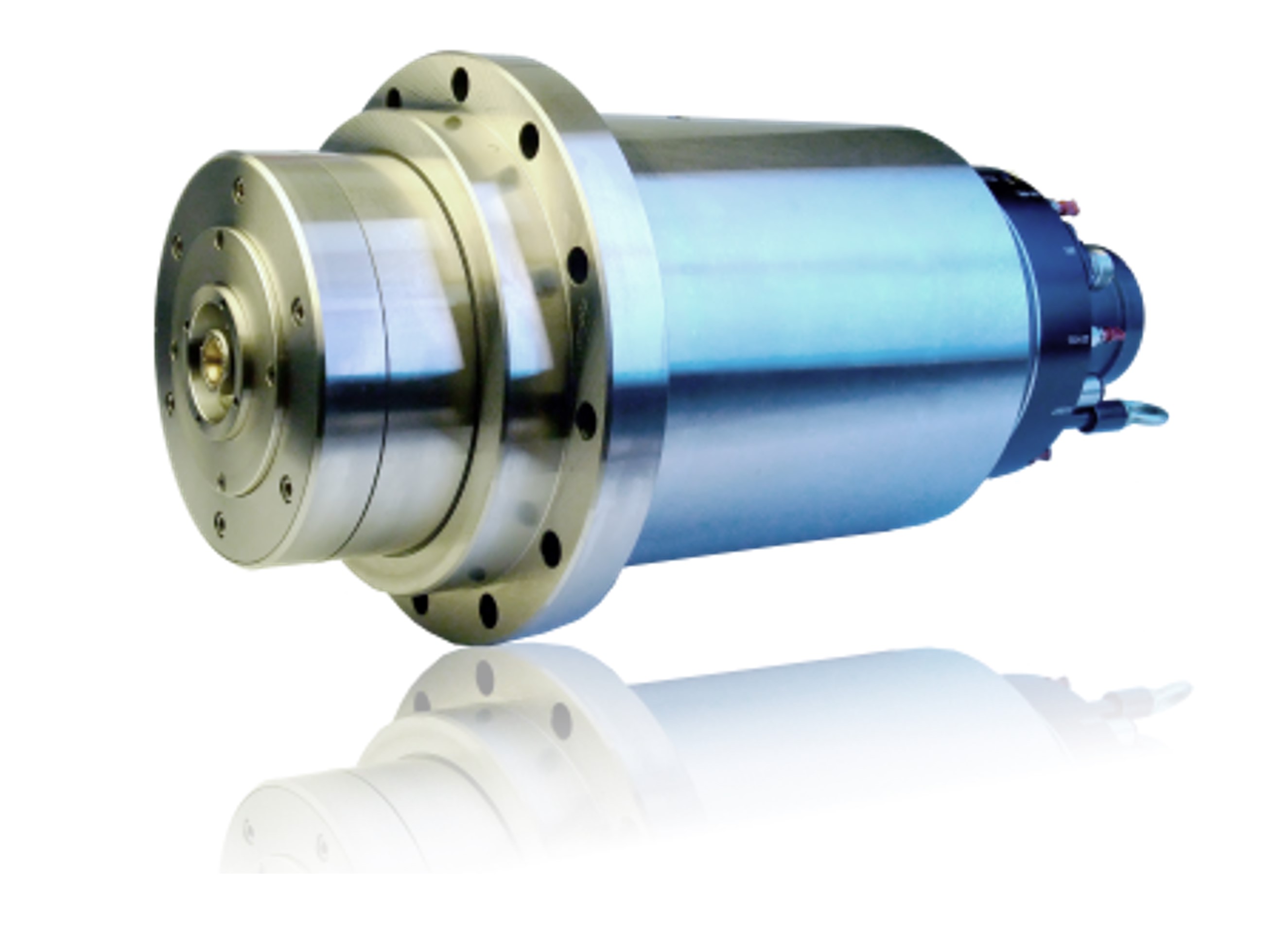

WELE MECHATRONIC CO., LTD.

Product Description :

1.立車主軸轉盤以進口交叉滾子軸承設計,確保重負荷的能力及長期的精度壽命。

2. Z軸226 mm方型滑枕搪孔軸採硬軌配Turcite B結構,VTC1612-CW標準行程900mm。

3.底座、立柱、橫樑、工作台等大型鑄件依製造需要,經由最新的3D設計,剛性最佳化,並以

多年經驗訂定有效的退火程序以消除殘餘應力,多年實際應用經驗,確實能達成有效的長期精

度保持性。

4.X、Z軸標準配備採用「雙編碼器」的「雙」半閉環回饋系統,經濟有效的提高各軸的定位精度。

(X、Z軸可選購德國Heidenhain或西班牙FAGOR光學尺)。

5.VTC-CW標準刀庫容量為16P(16儲位),車刀型式及分配數目可依客戶要求處理。

6.主軸箱等關鍵零件係利用自有的「大型臥式鏜孔機」及「大型高精度三次元量測儀(三座標量床)」

確實達成應有的加工精度,確保優良的組裝基礎。

7.承襲歐美先進工具機廠的標準,以嚴格維護的「1.2米x1.2米」高精密度的方形標準平板做為精密

精度的基礎,對各項關鍵零件進行精密鏟花(刮研),使機器的各處結合面和滑動面均能達到正確的

幾何精度,確保機器應有的精度和壽命。

8.搭配高規格的Fanuc數控系統,標準功能包含:15吋彩色液晶螢幕、Fanuc全鍵式操作面板、

2MB記憶容量、Ethernet網路接口、Flash記憶卡插口、剛性攻牙及各種特殊補間(插補)等多項

高規格功能,能經濟有效的滿足各種使用需求。

9.採用的各項配套零組件均經過長期使用驗證,可確保機器長期運行的可靠性。

10.完整的品檢測試流程,搭配先進的自動光學直準儀、雷射干涉儀、球桿檢測儀、線上動平衡儀等

精密檢測儀器,確保出廠的機器都能達到設計的性能和應有的功能。

11.經驗豐富的研發團隊,突破老舊的包袱,協助客戶達成各種特殊需求。

12.兼具經驗和熱誠的服務團隊和完整的服務體系,可以及時有效的讓用戶的機器長保最佳使用狀態。

TAIWAN MACHINE TOOL CO., LTD.

Product Description :

The CNC Tapping center, designed and manufactured by TMT, is your best choice in drilling and tapping work. The machine series employs a high speed traverse on the three axes to significantly increase drilling and tapping efficiency. The entire machine is ruggedly constructed to assure the highest machining accuracy.

-The casting parts of machine are manufactured from high quality Meehanite cast iron, rib reinforeced and stress released to assure it remains deformation-free year after year.

-Three axes slideways are mounted with precision linear ways. Extra large span between ways. High feed rate and superior stablility.

-Servo motor directly drives ballscrew, featuring high positioning accuracy without backlash problem.

HAWE Hydraulik Singapore Pte. Ltd. Taiwan Branch

Product Description :

Compact hydraulic power packs are a type of hydraulic power pack. They arecharacterised by a highly compact design, since the motor shaft of the electric drive also acts as the pump shaft. Compact hydraulic power packs are designed to supply hydraulic circuits with hydraulic fluid.

The compact hydraulic power pack type INKA consists of the tank, the integrated motor and the radial piston pump or gear pump directly attached to the motor

shaft. The directly mounted electronic communication box with integrated realtime operating system allows the operating state to be recorded and visualised. The

measured values of the integrated multi-sensor (including the motor speed) can be passed on to the higher-level machine controls via standardised interfaces and processed there.

The consistently modular design of the type INKA means that different usage volumes and delivery flows can be realised quickly and easily from the modular

system. Compatible, ready-for-connection, complete solutions can be assembled easily using a wide range of connection blocks and the valve banks that can be combined with them.

Features and benefits

■ Prepared for condition monitoring with integrated sensors and communication box

■ Optimum efficiency through under-oil motor cooling, direct power transmission,and sophisticated heat dissipation

■ Suitable for nominal operating modes S2 (short period operation) and S3 (periodic intermittent operation)

■ Resource-saving due to small oil filling volume

Intended applications

■ Machine tools and material testing

■ Hydraulic tools

■ Handling systems

■ Presses and processing machines

FAIR FRIEND ENTERPRISE CO., LTD.

Product Description :

1. Improve tools life and cutting efficiency, especially ideal for particular process requirements of brittle or hard、 high-temperature superalloy and composite materials.

2. Increased precision and quality of the workpiece to achieve excellent cutting results. (smooth edge)

3. Perfected ultrasonic control technology for easy selection, automatic frequency, and power adjustment.

4. The strong chipping of chassis concentrates the chips into the path as ensures high efficiency.

5. Anti-scale cover + KEVLAR armor material, used in glasses, ceramics super hard metal processing which can preventing dust protection system effectively.。

LEADWELL CNC MACHINES MFG., CORP.

Product Description :

The 5 axes simultaneous processing, can reduce the times of workpiece unloading and the requirement of the jigs, shorten the processing time and improve performance. C-axis table using the DD motor provides high torque and rigidity and can solve the traditional worm gear backlash and worn problems. High torque and efficiency of the spindle with a complete high-rigidity structure applied results in roughing to finishing can be completed on the same machine, suitable for machining hard materials and non-ferrous materials processing.

X-axis travel: 1300mm

Y-axis travel: 610mm

Z-axis travel: 610/750mm

Table size: 1480x610mm

Max. table load: 1600kg

Spindle speed: 12000rpm

C-axis speed: 800rpm

X/Y/Z-axis rapid traverse: 36/36/30 m/min

Tool storage capacity: 30T

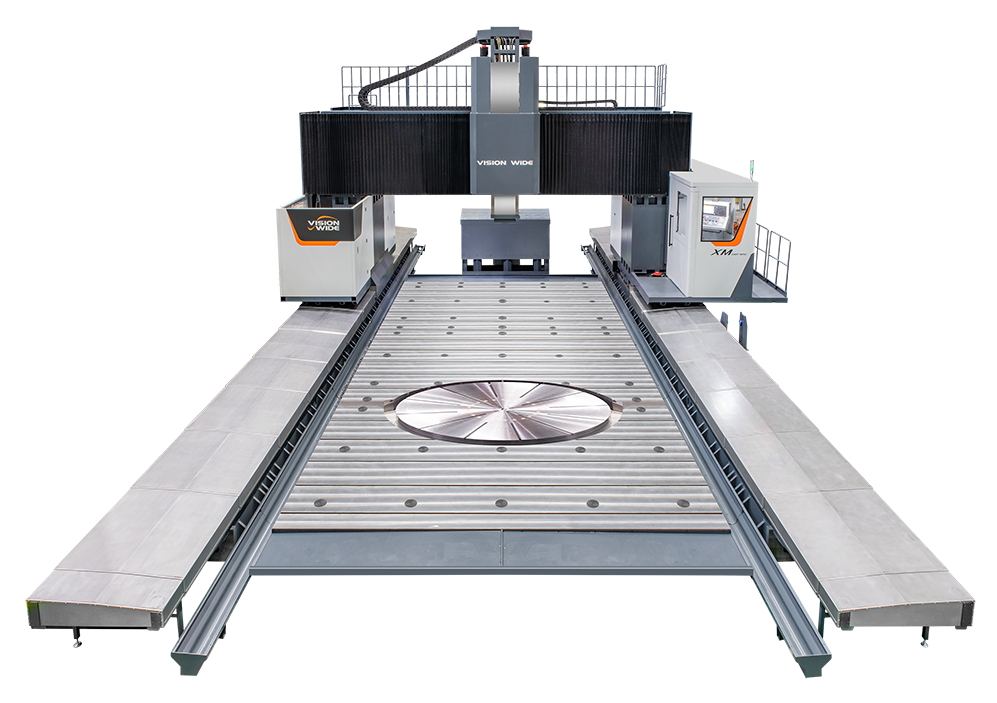

VISION WIDE TECH CO., LTD.

Product Description :

High Performance and Wide Application

XM series moving column machining center is a product developed for the machining needs of large-scale precision machinery, electric power, wind power, energy, petrochemical, transportation... and other equipment. It has:

Huge workpiece machining space: For precision machining of various types of structural parts, it can provide super large XYZ axis machining space.

• High-precise positioning: The high-standard geometric accuracy and positioning accuracy capabilities of the whole machine enable large-scale precision machining

• Heavy cutting capacity: Provide a variety of high-rated torque spindles to meet the processing and cutting capabilities of various materials.

• Fully automatic multi-face machining: This moving column machining center can be matched with various automatic attachment heads for high tangential speed mold surface machining and various types of precision parts complex angle machining, with excellent tool tip point error automatic correction function, and automatic additional head and tool exchange function, it can realize fully automatic machining performance.

• Milling and turning compound multitask: This moving column cnc milling machine can be equipped with a high-torque and high-speed vertical turning table to realize milling and turning compound automatic machining.

YING HAN TECHNOLOGY CO., LTD.

Product Description :

5-AXIS VERTICAL MACHING CENTER BELONGS LINEAR WAYS ON THREE AXES, X, Y, Z -AXIS TRAVEL: 800x600x550mm, MEEHANITE CAST IRON IS TEMPERED FOR STRESS RELIEF TO ENSURE STRUCTURAL STABILITY WITHOUT DEFORMATION. REINFORCED COLUMN BASE GREATLY INCREASES STRUCTURAL STRENGTH AND WILL EXHIBIT ULTRA-HIGH STABILITY DURING HIGH SPEED OPERATION. WITH THE EQUIPMENT OF CNC TILTING ROTARY TABLE, THE MACHINE IS ABLE TO PERFORM 5-AXIS MACHINING, IT CAN MACHINE COMPLEX, MULTI-SIDED PARTS IN A SINGLE SETUP, THEREBY REDUCING SETUP TIME WHILE INCREASING PART ACCURACY.

CAMPRO PRECISION MACHINERY CO., LTD.

Product Description :

NV series provide more Y-axis and more working area to meet various demands.

Heavy-duty roller type linear guideways on 3 axes which provide integration of heavy cutting ability from box way and fast movement ability from linear guide way.

Z-axis servo motor with brake replaces counter-balance to provide optimal surface accuracy on 3D machining.

Pretensioned class C3 precision ballscrews on 3 axes help to eliminate blacklash.

Bearings with dust-protection device are assembled by 3 sets both in the front and rear.

One-piece column which designed with shoulder to support tool magazine to decrease vibration and increase the machine stability while tool changes.

Optional max. 4/5-axis table diameter allows more working area and less interference between cutting tools and workpieces.