Theme

Digital Transformation

Green Transformation

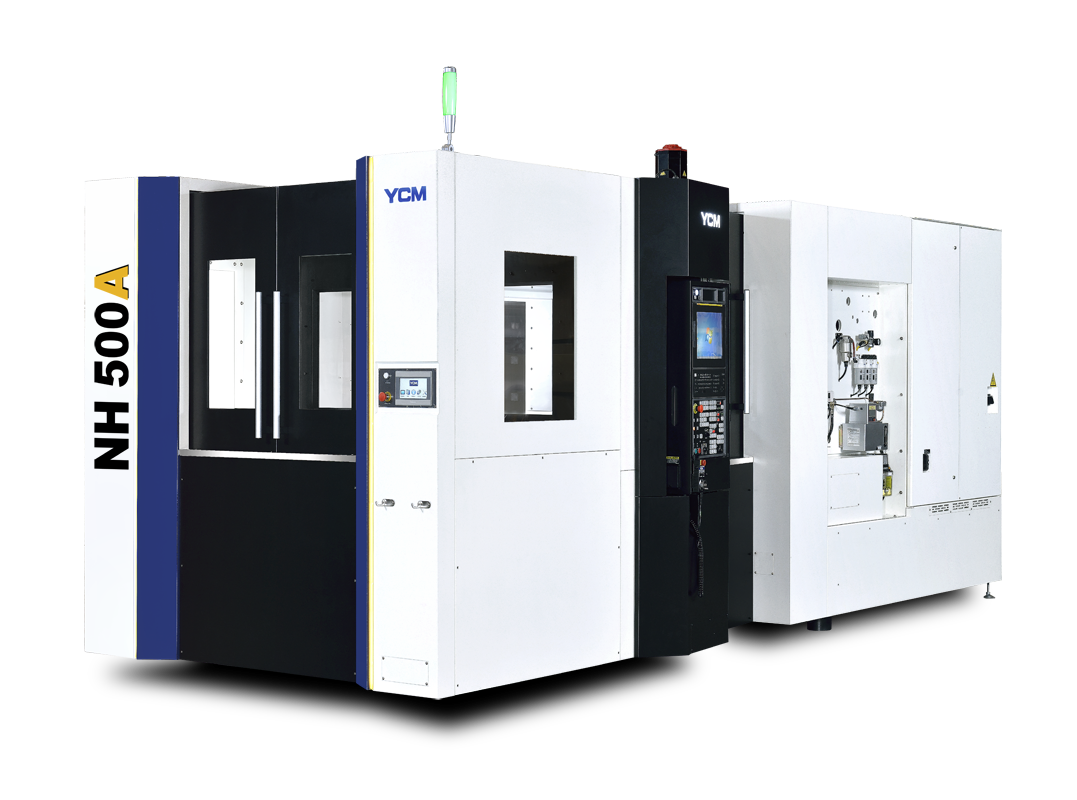

YEONG CHIN MACHINERY INDUSTRIES CO., LTD.

Product Description :

High rigidity and high accuracy NH500A provides the best solution for automotive, precise and mechanical parts industries.

■ High rigidity T-base foundation with rib construction

■ One-piece casting spindle headstock and dual-wall column design

■ Powerful Built-in spindle with Micro oil-air lubrication for angular ceramic ball bearings prolongs spindle life

■ High precision roller type guideways on all axes

■ High precision pallet indexing system.

TONGTAI MACHINE & TOOL CO., LTD.

Product Description :

‧HTT-500, the 5-axis horizontal machining center, is Tongtai's new solution of process integration which will definitely meet the demands on high-mix low-volume manufacturing.

‧Excellent machine rigidity and stability to ensure high accuracy during precision machining.

‧Orthogonal mechanical coordinate system for easy programming and enhance the precision and efficiency of machining.

‧Central chip removal system effectively prevents the problem of internal temperature rise from accumulated cutting chips and reduces the environmental variables for higher precision.

‧Equipped with APC (auto pallet changer) system to shorten the machine idle time.

‧Built-in thermal compensation function to ensure ideal machining accuracy under different temperature conditions.

TAIWAN MACHINE TOOL CO., LTD.

Product Description :

The CNC Tapping center, designed and manufactured by TMT, is your best choice in drilling and tapping work. The machine series employs a high speed traverse on the three axes to significantly increase drilling and tapping efficiency. The entire machine is ruggedly constructed to assure the highest machining accuracy.

-The casting parts of machine are manufactured from high quality Meehanite cast iron, rib reinforeced and stress released to assure it remains deformation-free year after year.

-Three axes slideways are mounted with precision linear ways. Extra large span between ways. High feed rate and superior stablility.

-Servo motor directly drives ballscrew, featuring high positioning accuracy without backlash problem.

LITZ HITECH CORP.

Product Description :

新一代的VB系列立式加工中心機,X/Y/Z軸採用全硬軌設計,主軸頭為齒輪傳動系統,實現了在低轉速輸出強大的切削力,搭配高剛性的主軸設計,滿足了重切削和高速切削的要求

GENTIGER MACHINERY INDUSTRIAL CO., LTD.

Product Description :

- “U” shaped base is one-piece fabricated for maximum stability and rigidity.

- X-axis federate is transmitted through a specially designed rotating nut, it prevents the ball-screw runs out during rotating and makes feed motion response faster.

- Coolant inter ball-screws on three-axis prevent ball-screw deformation, it suppresses thermal growth and thermal displacement on the ball-screw while assuring smooth feed motions and high positioning accuracy.

SHE HONG INDUSTRIAL CO., LTD.

Product Description :

Delivers higher stability with gantry design<br />

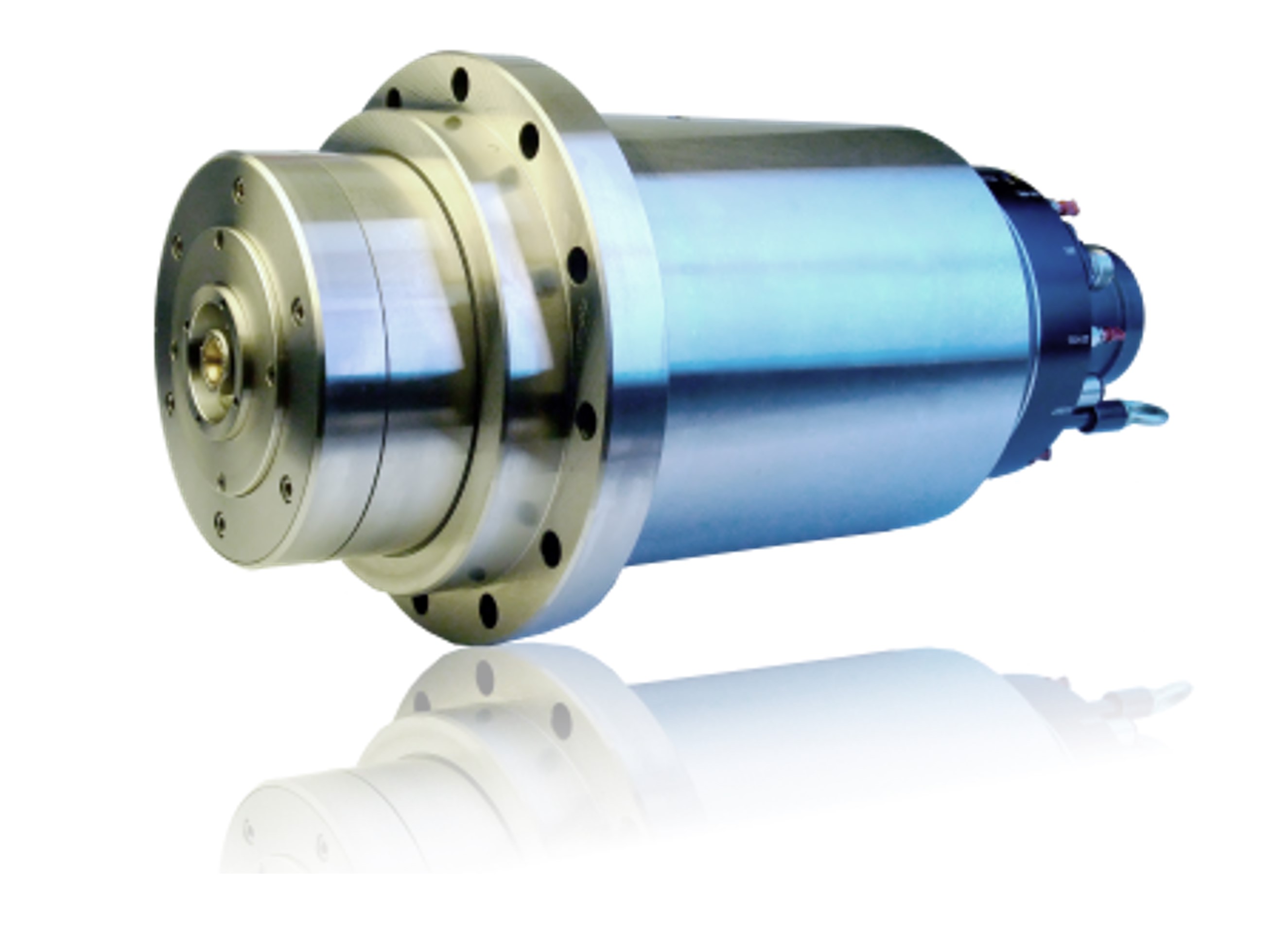

SPINDLEX TECHNOLOGIES CO., LTD.

Product Description :

Spindle housing diameter : 210mm

Tool interface : HSK-A63

Maximum speed (rpm) : 20,000 RPM

Lubrication : Oil-Air

Motor power : 18/22.5 KW

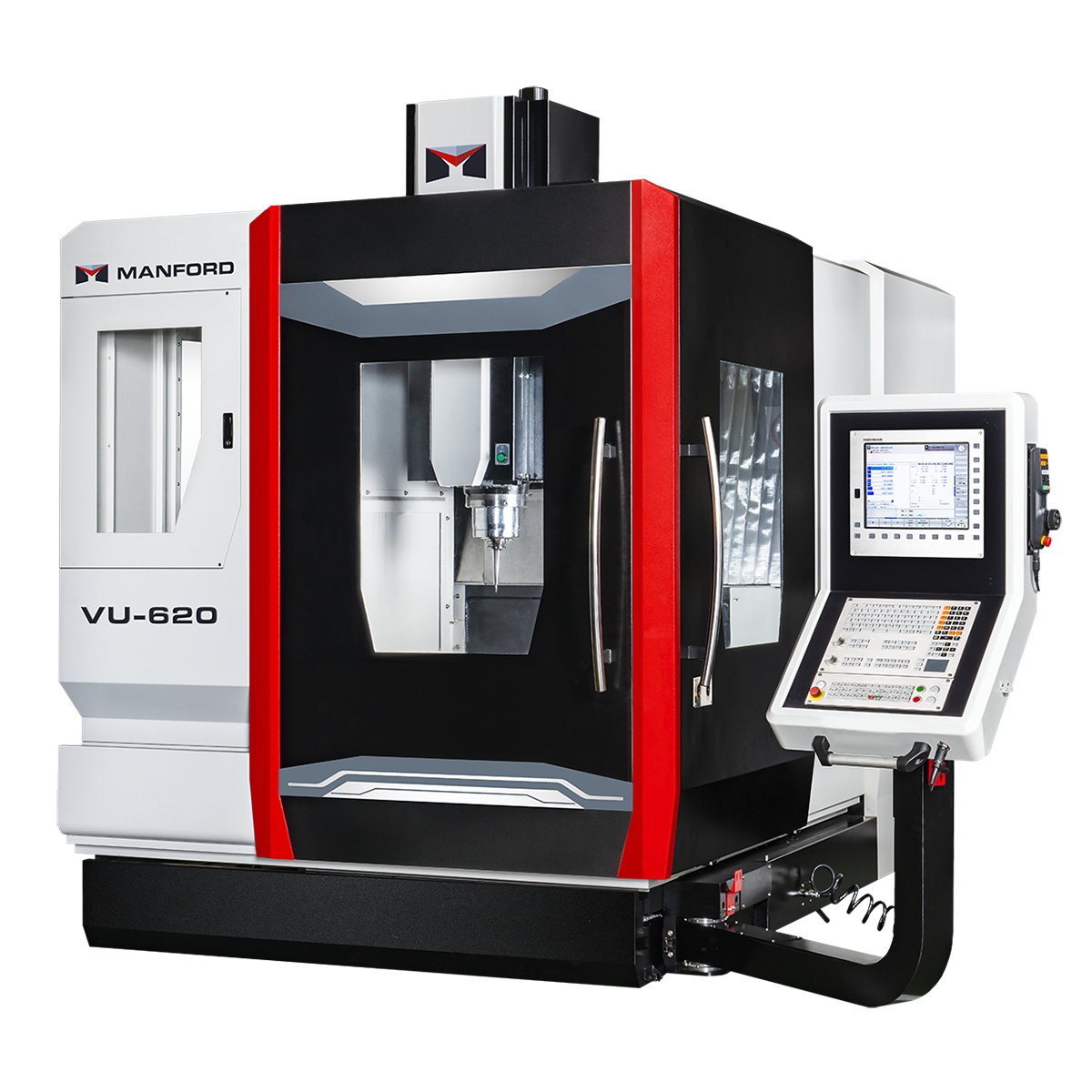

MANFORD MACHINERY CO., LTD.

Product Description :

The casting body with high rigid structure and industrial aesthetics adopts angular shape, and the three-color corporate identity of red, black, and white.

The side door is used to observe the workpiece processing and calibrate the workpiece.

The handle of the operation box is conveniently designed for front and rear and 180° rotation.

Table size: 850 x 500 mm

Pallet changing time: 11 ~ 13 sec

Table positioning accuracy: 0.01 mm

MANFORD MACHINERY CO., LTD.

Product Description :

Turnkey solution of VU-620 product line enables Manford to process and optimize parts efficiently, enhance productivity and accuracy. VU-620 adopts low-pollution components and complies with eco-friendly regulations. Occupying compact floor dimensions is also one of the features of VU-620.

VU-620 offers high speed, high accuracy and more reliable quality. Twin doors design with wide open space is easy for loading workpiece. Movable column C-shape provides superior rigidity. Rotary table with one-piece iron casting provides excellent ductility and greater anti-vibration. Rotary table selection: standard worm gear, or double DD motor.

EUMACH CO., LTD.

Product Description :

GVM-800U 專為高精度複雜多曲面銑削而設計,只需一次裝夾,甚至可以車削。從靜態剛性和動態質量的角度來看,每個關鍵部件的堅固框架都經過了很好的優化,以成為最高性能的天車式五軸加工中心。 雙Y軸驅動龍門型結構,絕對抑制了極高速(48m / min)加速/減速產生的振動。不僅可以提高生產前置時間,加工精度,還可以通過緊湊的設計優化工作環境,提高公司的整體管理水平。

直接驅動工作台由二個扭矩電機驅動,A和C軸各一個,最大速度50/100RPM,最大負載920/1200kg,旋轉角度A/C軸±125゚/ 360゚,達到新的高水平動態銑削和車削操作!

刀庫是由交流伺服電機驅動,以簡單,快速,無故障和極其平滑的刀具交換,標準32把刀及更多選擇。高速內藏式銑/車削電主轴18000~24000RPM可供選擇。搭配HEIDENHAIN TNC640,15”螢幕的五軸連動控制器,HEIDENHAIN高精度三軸光學尺,該加工中心用於飛機渦輪元件的加工及鋁製汽車輪圈高速表面處理提高了生產力。

TSYR TZUN INDUSTRIAL CO., LTD.

Product Description :

PRODUCT FEATURES

FM-35DL Comes with drilling force control unit for Auto-feeding:

When drill bit is worn out, this unit will drive feeding intermittently or stop feeding. Once feeding becomes difficult while making a hole, please replace a new drill bit or re-sharpen the worn out one in order to protect both drilling tool and machine body from being damaged.

FM-35DL Comes with two intermittent breaking rates for breaking chips:

Choose different feeding rates according to different drill bits and material to perform Auto-feeding operation. This device can break chips intermittently and discharge them while Auto-feeding is processing, so that chips would not roll on drill bit.

Easier to discharge chips.

The machine body is with height adjustment. It’s suitable for both lone and short annular cutters as well as general chuck which is for holding drill with straight handle.

The general chuck is applicable for holding drill which is with straight handle for drilling smaller holes(from 8-13mm).