Theme

Digital Transformation

Green Transformation

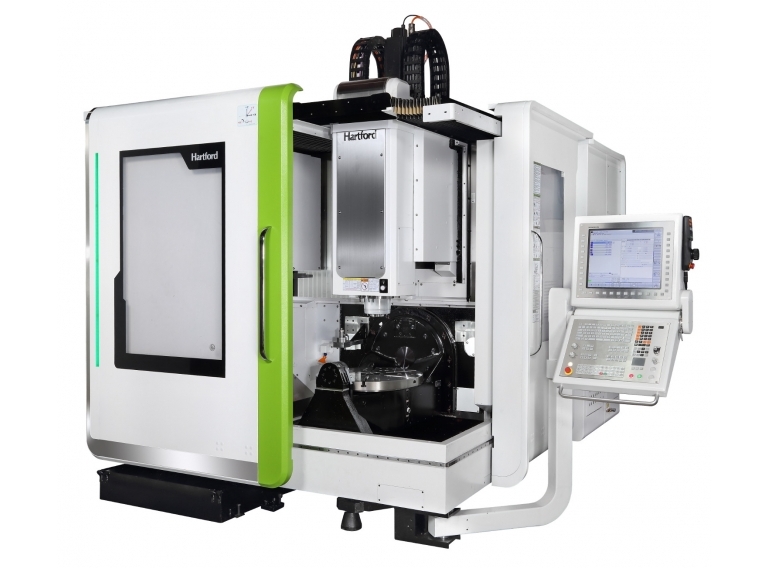

LEADWELL CNC MACHINES MFG., CORP.

Product Description :

The 5 axes simultaneous processing, can reduce the times of workpiece unloading and the requirement of the jigs, shorten the processing time and improve performance. C-axis table using the DD motor provides high torque and rigidity and can solve the traditional worm gear backlash and worn problems. High torque and efficiency of the spindle with a complete high-rigidity structure applied results in roughing to finishing can be completed on the same machine, suitable for machining hard materials and non-ferrous materials processing.

X-axis travel: 1300mm

Y-axis travel: 610mm

Z-axis travel: 610/750mm

Table size: 1480x610mm

Max. table load: 1600kg

Spindle speed: 12000rpm

C-axis speed: 800rpm

X/Y/Z-axis rapid traverse: 36/36/30 m/min

Tool storage capacity: 30T

SHENG YU PRECISION MACHINE CO., LTD.

Product Description :

The general-purpose two-way horizontal CNC drilling and tapping machine can be combined with various industries to provide the best processing solution for multi-axis machine tools to improve efficiency and reduce costs. It is a processing tool that belongs to you.

NUMEN MACHINERY CO., LTD.

Product Description :

Delta 6 is designed for new dimensions in precision, contour accuracy, surface quality and productivity. Maximum dynamics, precision performance milling and HSC machining are accurately executed. Offering wide range of applications including electronic watch, optical, medical and die mold.

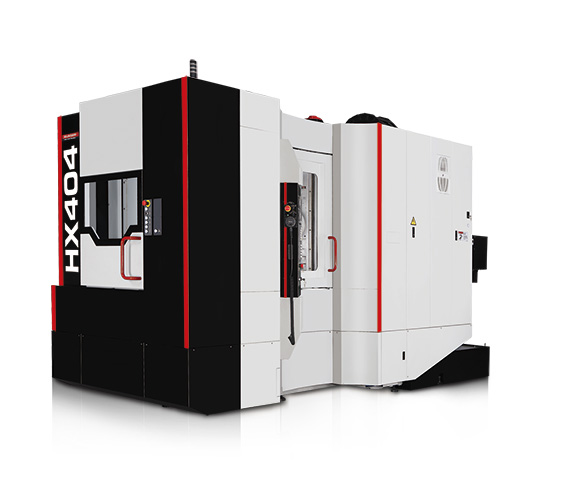

QUASER MACHINE TOOLS, INC.

Product Description :

The large Z axis span of HX404 allows the machine to deal with high work pieces and to strengthen machining stability with high rigidity.

The HX404 utilizes W-shaped Z axis telescopic covers to deal with stacked chips, combined with the integrated coolant wash, internal chip augers and external lift up chip conveyor, enhances the management of chip disposal.

In addition, the easy operation and ergonomic accessibility for HX404 allow s operator easily to reach machining work piece, spindle and load/unload station. The HX404 also features small floor space, which makes the best space utilization for clients.

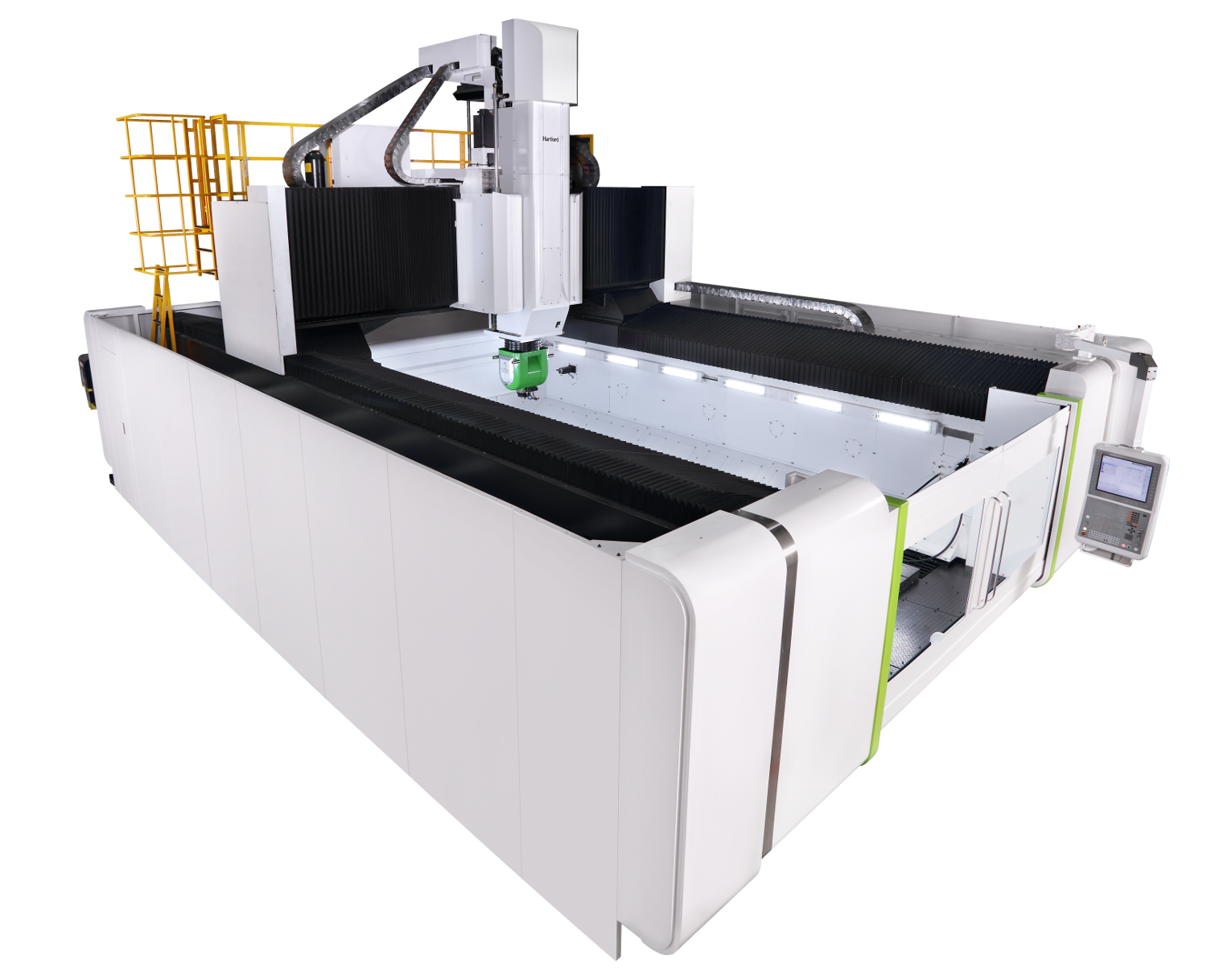

GUANDA INTERNATIONAL MACHINERY CO., LTD

Product Description :

Specifically designed for steel beam / structural steel processing. STD 105 equips with 3 spindles working simultaneously. Each spindle works with a BT-40 ATC, which increases the working efficiency and flexibility.

We apply MQL (minimum quantity lubrication) not only to improve the working environment but also to reduce the operation cost.

We provide various automation solutions to meet your needs.

YIDA PRECISION MACHINERY CO., LTD.

Product Description :

The MT-900 has a 5-axis milling head, two turrets, a tool magazine and twin spindles.

The design layout allows for maintaining a large work envelope for both lathe operations-turning and milling.

All six sides of a part can be machined without an operator having to manually resettle the workpiece, so nearly any parts can be machined in an automated manner.

NUMEN MACHINERY CO., LTD.

Product Description :

*High-rigidity structure design, using C3 precision ball

screw for axial feed and direct drive with servo motor.

* X/Y/Z axes installed with roller type of linear slide way

to ensure rigidity of axial movement and fast feed rate.

* Direct drive spindle.

* Suitable for various processing industries.

* 4th axis / 5th axis applications.

TONGTAI MACHINE & TOOL CO., LTD.

Product Description :

‧HTT-500, the 5-axis horizontal machining center, is Tongtai's new solution of process integration which will definitely meet the demands on high-mix low-volume manufacturing.

‧Excellent machine rigidity and stability to ensure high accuracy during precision machining.

‧Orthogonal mechanical coordinate system for easy programming and enhance the precision and efficiency of machining.

‧Central chip removal system effectively prevents the problem of internal temperature rise from accumulated cutting chips and reduces the environmental variables for higher precision.

‧Equipped with APC (auto pallet changer) system to shorten the machine idle time.

‧Built-in thermal compensation function to ensure ideal machining accuracy under different temperature conditions.