Theme

Digital Transformation

Green Transformation

HC FENG CO., LTD.

Product Description :

4 in 1 Coolant Purification System

1. Filtering floating debris and dirty particles

2. Oil/Water Separation, removes tramp oil down to 5% water content

3. Ozone Disinfection, eliminates bacteria and cleaned fluid backflow

4. Automatic control panel and pH detect device

YEONG CHIN MACHINERY INDUSTRIES CO., LTD.

Product Description :

Most Popular High Performance NSV106AS is well suited for superior surface finishing works, specially in automotive, job shop and electronics industries. ■ Large delta machine column and base ensure the highest stability during high speed movement■ High precision roller type guideways on all 3 axes■ High precision linear guideway with 6 slide blocks on X-axis■ High performance YCM in-house designed spindle with low vibration to achieve excellent finish

YIDA PRECISION MACHINERY CO., LTD.

Product Description :

1. T structure bed with high-quality cast-iron frame for enhanced rigidity and stability.

2. Extremely rigid mobile column with linear guide ways ensures stability and cutting accuracy while allowing rapid traverse of the X, Y and Z axes.

3. High rigidity roller type linear guideways, rugged massive linear guideways on X, Y and Z axes maintain precision and ensure a rapid traverse rate.

MANFORD MACHINERY CO., LTD.

Product Description :

The casting body with high rigid structure and industrial aesthetics adopts angular shape, and the three-color corporate identity of red, black, and white.

The side door is used to observe the workpiece processing and calibrate the workpiece.

The handle of the operation box is conveniently designed for front and rear and 180° rotation.

Table size: 850 x 500 mm

Pallet changing time: 11 ~ 13 sec

Table positioning accuracy: 0.01 mm

KAO FONG MACHINERY CO., LTD.

Product Description :

5-axis synchronous machining of the KMU series can be used for multi-faceted processing of workpiece clamping positioning at one time or processing deep hole mold and inverted hook area.

Three-axis structure using box-type construction design, which can effectively improve the rigidity of the machine.

X / Y / Z axis with high rigidity roller type linear guideway, with high rigidity, fast moving, low wear and other characteristics, which can greatly enhance the processing dynamic precision and stability and effectively increase production efficiency.

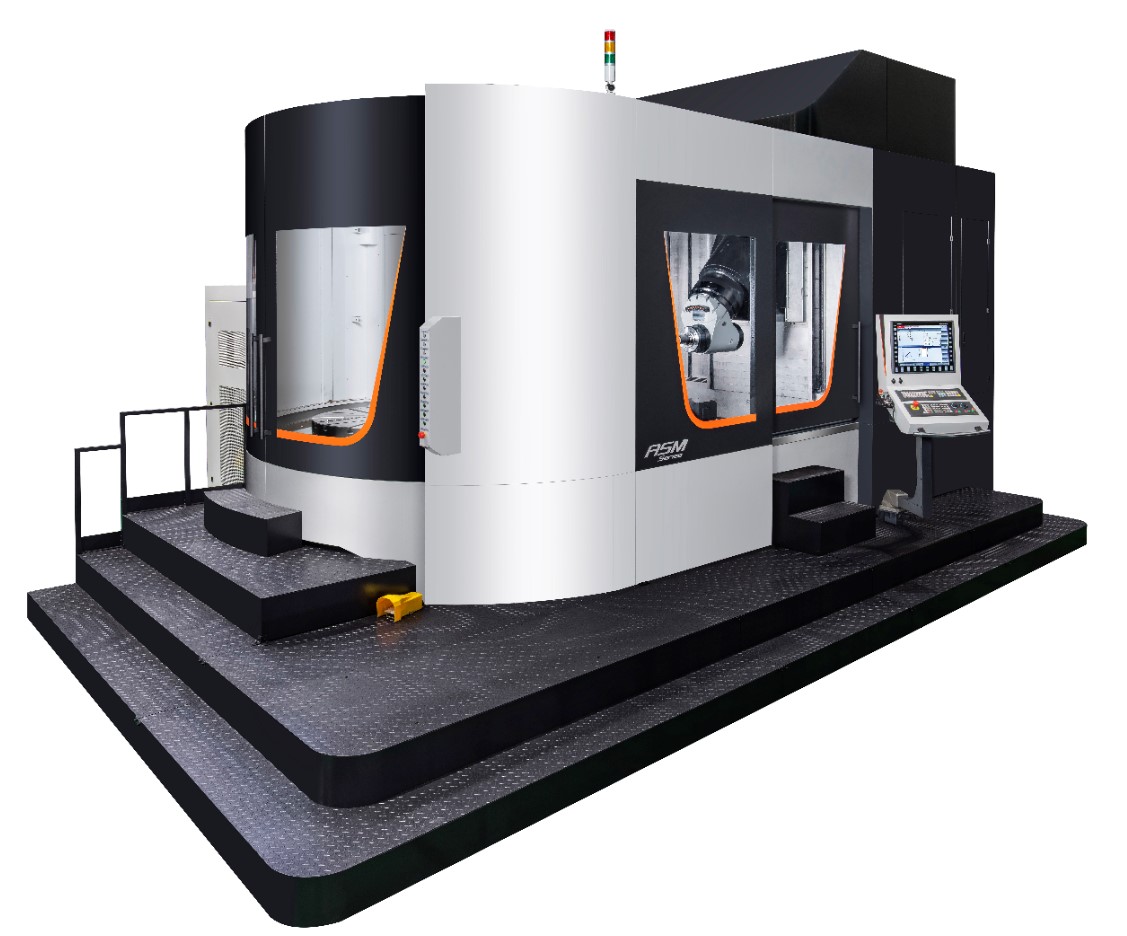

VISION WIDE TECH CO., LTD.

Product Description :

• ASM is the first 5-axis CNC turning and milling machining center of Vision Wide, and it is particularly designed for delicate cylindrical components machining featuring high acceleration, rapid feed-rate and synchronized axes machining, especially for aerospace components, tire molds, turbine blades and aluminum parts.

ASM accessorizes with 5-axis universal head and rotary shafts built-in D.D motor. Through topology analysis, ASM realizes the best distance between tool center point and B-axis transmission

• Positioning P0.006mm

• Repeatability Ps0.0055mm

• Spindle thermal compensation 0.02 mm

• Rapid Traverse 40m/min

• Acceleration 0.3G

• Cutting Feed rate 24 m/min

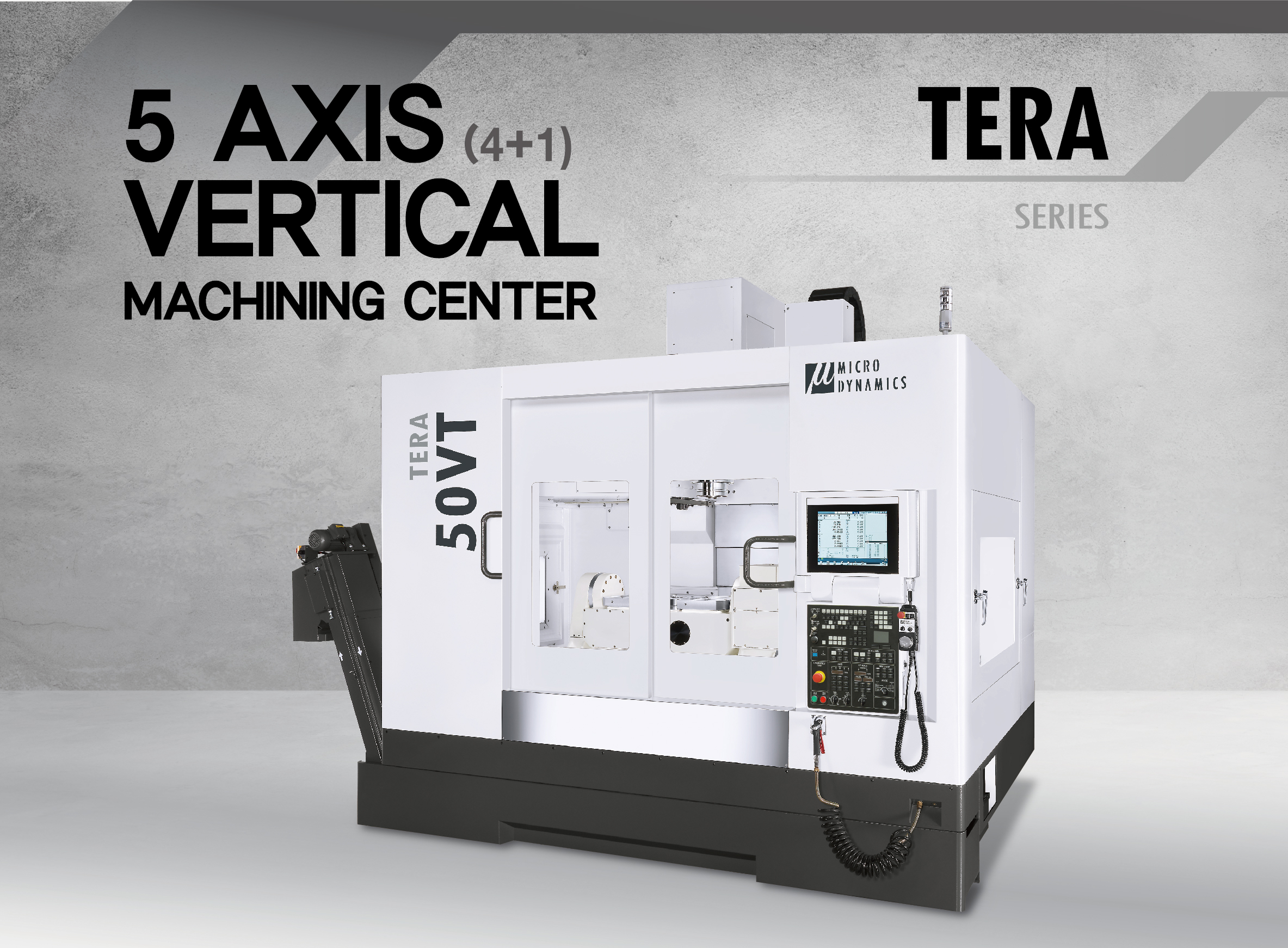

INNOSERV FA INC. TAIWAN BRANCH (BVI)

Product Description :

Micro Dynamics Vertical Machining Center Line opens a new era in multi-purpose and versatile machining centers. Compact, durable, powerful, strong and accurate, the MEGA/TERA Series starts a revolution in the market: the smallest C-frame machines provide powerful and precise results for manufacturers of dies and molds, aerospace, automotive, semi-conductor, job shops and general machine sectors.

The MEGA/TERA Series has been designed with the latest in technology being utilized throughout the machine with productivity in mind. From its EtherNet/IP architecture for easy automation and integration into systems and cells, to its Motion Control for fast and smooth operations used in all industries, the MEGA/TERA Series has quickly become one of the industries leading machine tool lines of Vertical Machining Centers.

The MEGA/TERA Series has been refined through years of research and development of new technologies that greatly enhance the machines for the rigors of the Mold and Die industry.

All series are equipped with

■ 15,000 rpm Built-In Spindle

■ Thermal Compensation (DYPEC)

■ Micro Dynamics HMI

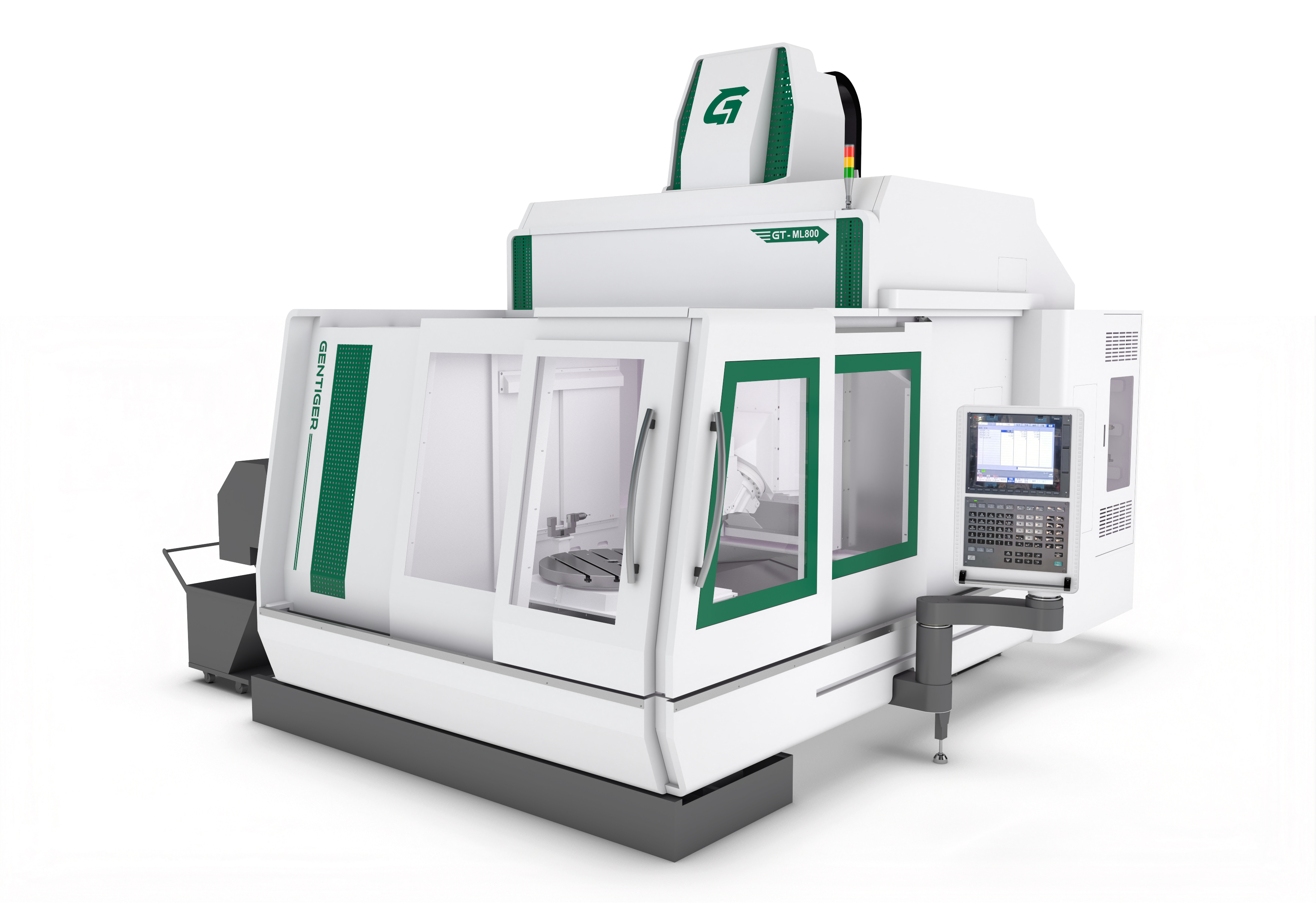

GENTIGER MACHINERY INDUSTRIAL CO., LTD.

Product Description :

• Closed-type double-column structure, it increases structure dramatically increases the structural rigidity of the machine and maintains extraordinary stability at all times.

• Roller-type linear guideway on three axes, it achieves high loading resistance, high rigidity, long service life, low thermal growth, and low noise.

• Three linear guideways on the Y axis, it provides more stable support for the spindle head, which contributes to upgraded stability in machining.

• The 45° vertical horizontal swiveling head is applicable for both vertical and horizontal machining, increasing flexibility in machining applications.

NUMEN MACHINERY CO., LTD.

Product Description :

* Double column structure and high rigidity design can

provide mold processing industry with high precision

and high efficiency of the performance.

* The superior cutting rigidity, more user-friendly

operation mode and machine stability can improve

the efficiency of operators.

CAMPRO PRECISION MACHINERY CO., LTD.

Product Description :

NV series provide more Y-axis and more working area to meet various demands.

Heavy-duty roller type linear guideways on 3 axes which provide integration of heavy cutting ability from box way and fast movement ability from linear guide way.

Z-axis servo motor with brake replaces counter-balance to provide optimal surface accuracy on 3D machining.

Pretensioned class C3 precision ballscrews on 3 axes help to eliminate blacklash.

Bearings with dust-protection device are assembled by 3 sets both in the front and rear.

One-piece column which designed with shoulder to support tool magazine to decrease vibration and increase the machine stability while tool changes.

Optional max. 4/5-axis table diameter allows more working area and less interference between cutting tools and workpieces.