Theme

Digital Transformation

Green Transformation

HC FENG CO., LTD.

Product Description :

The combination of centrifugal device and magnetic separator is perfect for processing water-and oil-based cutting fluids and sludge containing magnetic dusts and shavings. The shaving removal is quick and effective, which saves a lot of time waiting and minimizes the costs to replace consumables.

PROTH INDUSTRIAL CO., LTD.

Product Description :

1.A : Auto-cross H : Hydraulic longitudinal R : Rapid up/down.

2.Overall architecture (horizontal module) : Overall structural design optimization /lightweight/stiffness strengthen.

3.Built-in spindle (15HP) with 20 inches grinding wheel.

4.Workpiece shape : flat grinding/step/plunge grinding.

5.Machine drive : Cross and vertical liner guide way, longitudinal double V guide way.

HC FENG CO., LTD.

Product Description :

4 in 1 Coolant Purification System

1. Filtering floating debris and dirty particles

2. Oil/Water Separation, removes tramp oil down to 5% water content

3. Ozone Disinfection, eliminates bacteria and cleaned fluid backflow

4. Automatic control panel and pH detect device

Fulson Industrial Co., Ltd

Product Description :

This high precision surface and form grinder has been specially developed and improved in recent years.

The tool cabinet in machine base is specially designed for operator’s convenience (618m).

The interlock between electrical cabinet door and power supply is established to ensure safe operation.

The maximum distance from table surface to spindle centerline is 18" (450mm) which provides more clearance for grinding.

The sping loaded type table travel stops will dampen theovertravel caused by abnormal operations (618m).

The optimum span of double V crossfeed guideways is designedbased on bending moment, kinematics supporting force.

All essential castings are mode of high grade of meehanite castiron that is stress relieved through annealing to eliminateinternal stress.

With the greatest stiffness and stability of the castings, this machine is suitable for both precision surface grinding and formgrinding .

This grinder is offered with one-full-year limited warranty formechanical and electrical parts .

FALCON MACHINE TOOLS CO., LTD.

Product Description :

These words describe the driving forces behind the design of our SMART-IV CNC surface grinding machines. They’re the standards required by the medical, automotive, mining, semiconductor, aerospace, injection mold making and job shop industries in order to meet current and future market needs and pave the way to factory automation.

This series is capable of producing complicated shapes for highly accurate workpieces along with finer finishes. The heavy-duty slide rails, one-piece base casting and hardened wheelhead guideways create a solid, rigid machine structure that minimizes vibration, movement and displacement.

Chevalier’s user-friendly grinding machines include our exclusive PC-based SMART iControl featuring conversational programming.

Combined with TaskLink, it allows operators to create their own programs for generating complex grinding tasks in a single cycle—without an engineering degree.

FALCON MACHINE TOOLS CO., LTD.

Product Description :

Improved grinding performance, precision and stability

Chevalier's FSG-20/24ADIV Series of surface grinders now includes four new machine sizes, along with several newly designed features: a traveling column structure to further reduce vibration and achieve higher accuracy; a spindle that can withstand heavy load grinding; and a double-V guideway for smooth, stable longitudinal movements. Fully supported worktable design. Maximum table speed: 30 m/min (98.4 fpm), increases processing efficiency. Integrated machine-body temperature control system greatly improves accuracy and stability.

These four larger sizes, along with the entire FSG-20/24ADIV Series, offer several design features to shorten processing and non-processing preparation while delivering high-precision workpieces: iSurface control, variable speed spindle, constant surface speed, smart grinding path and in-machine manual dynamic balancing.

The driving forces behind this series pave the way to smart manufacturing by meeting the current grinding demands and standards required by the automotive, electric vehicle, mining, aerospace and job shop industries.

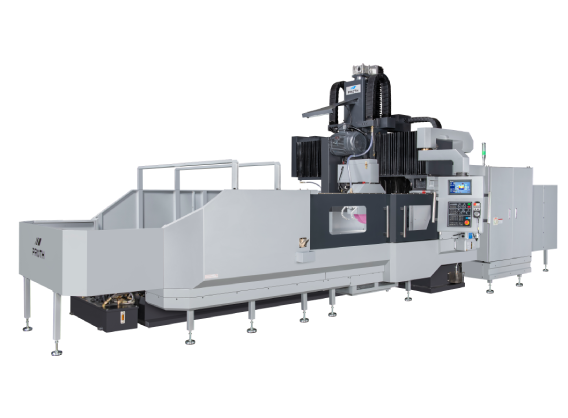

PROTH INDUSTRIAL CO., LTD.

Product Description :

1.Cross feed and vertical feed are driven by servo motors.

2.Horizontal spindle head,vertical spindle head(optional).

3.Double column construction and extra large diameter of rotary table.

4.The rotary table running is driven by a powerful motor and controlled by frequency inverter.

5.Two axes are servo controlled.

Fulson Industrial Co., Ltd

Product Description :

These high precision surface grinders have been specially developed and improved in recent years. The optimum span of double V crossfeed guideways is designed based on bending moment, Kinematics and supporting force. All essential castings are made of high grade of cast iron that is stress relieved through annealing to eliminate internal stress. With the greatest stiffness and stability of the castings, these machines are suitable for precision surface grinding. These grinders are offered with one-full-year limited warranty for mechanical and electrical parts.

BENIGN ENTERPRISE CO., LTD.

Product Description :

• Hydraulic longitudinal feed. Direction changed by sensor & solenoid valve.

• Automatic cross feed. Direction changed by stopping dog and limit switch.

• Manual vertical feed

• Saddle type

• Automatic lubrication

• Longitudinal: one flat and one V way

• Cross: 2 V way

• Optional AD5 automatic down feed and magnetic chuck

PROTH INDUSTRIAL CO., LTD.

Product Description :

PSGC-50100E Features :

1. E - Environmentally friendly, Belt-driven and quiet.

2. The controller adopts graphic display, and the operation is simple and easy to learn.

3. Dressing on the table for efficient circumferential and face dressing.

4.Machine drive : Three-axis servo.

PROTH INDUSTRIAL CO., LTD.

Product Description :

1.A : Auto-cross H : Hydraulic longitudinal R : Rapid up/down.

2.Hydraulic System : Two single-acting hydraulic cylinders are used with their piston rods anchored at very specific positions.This enhances rigidity and creates a very stable table motion; table float is eliminated.

3. Grinding spindle : The precision high rigidity spindle is of a cartridge type design. This provides for easier accessibility and service when maintain is needed.

4. Upgradable CNC numerical control.