Theme

Digital Transformation

Green Transformation

GRINTIMATE PRECISION INDUSTRY CO., LTD.

Product Description :

a.Equipped with exclusive high rigidity hydrostatic rotary table, static rigidity greater than 400kgf/μm, Φ600/800table with a load capacity of >10000KG.

b.Mitsubishi/Fanuc controller available, with human-machine interface(HMI) which features fast communication and convenient for user-friendly operation.

c.The high rigidity of our hydrostatic spindle both radially and axially enables our spindles to produce a wide range of finishes-from speedy heavy cutting of >0.3mm to mirror-like finish.

d.To maximize stability and load capacity, the Y-axis(up/down) and the Z-axis (forward/backward) of the grinding wheel spindle are equipped with SCHNEEBERGER/THK/NSK lineal guideway.

e.Equipped with THK/NSK high precision ballscrews, ensuring the zero backlash feeding.

f.Our products are on hundred percent designed and manufactured in Taiwan. To guarantee the stability of machine, all of the cast components go through a pressure relieve process

KO-YAN PRECISE MACHINERY CO.,LTD

Product Description :

GO-354 CNC Cylindrical Grinding machine combines plunge feed grinding angular feed grinding in one with high investment efficiency. The GO-354 exhibits extraordinary machining accuracy with circularity reaching 0.8 um. It is compactly constructed, occupying a small floor area. Outstanding machine features also include high efficiency, high precision and high productivity.

Machine Features

-Plunge and angular feed grinding.

-Highly rigid machine structure ensures the best possible stability during grinding.

-X, Z-axis are designed with ¡¨V¡¨ and flat slideways.

-Equipped with DITTEL audio sensor for monitoring the grinding quality.

-The tailstock has air floating function.

-Helical grinding and non-circular grinding (optional).

-Grinding speed can reach 50

m/min.

-Circularity accuracy: 0.8 um.

-This machine is equipped with a FANUC Oi-TF CNC controller.

-Selection of various parts loading / unloading devices (optional).

-Measurement system on machine (optional).

-Automatic balancing system can display the unbalanced condition of grinding wheel (optional).

E-TECH MACHINERY INC.

Product Description :

EGM series is a combinations of grinding operations for internal, external, end-face, groove, radius, internal and external step, and taper grinding can be executed in one chucking. Thus, it greatly increases grinding efficiency and also ensures better concentricity and accuracy of the ground parts.

KO-YAN PRECISE MACHINERY CO.,LTD

Product Description :

Turret wheelhead G1(OD), G2(OD), G3(ID), for complex workpiece, simplify processing program, once and for all, improve the utility of equipment.Workhead : Use FANUC servo motor, high torque and high stability .Power Transmission : precision ballscrew with servo motor drive and HEIDENHAIN linear encoder,improve axial motion’s positioning accuracy.Grinding wheel:use built-in spindle which is high rigidity and high torque.Also, can according to customer needs to choose the degree of wheelhead under the range of -10〫~ 240

E-TECH MACHINERY INC.

Product Description :

ECG series high precision centerless grinder is different from other competitors, we use spectrum analyzer to precisely the machine base inner ribs and casting thickness for greater rigidity. We offer hydrodynamic alloy bearing spindle with best rotation accuracy, suitable for heavy duty jobs, and drastically increase the spindle longevity.

E-TECH MACHINERY INC.

Product Description :

EGP-2520CNC is a high-efficiency cylindrical grinding machine with ultimate reduction in footprint. With a floor space requirement of less than 1.8m2 and 500mm diameter grinding wheel, it is suitable for small workpieces machining. Distance between center is designed to be 200mm, the center height is 125mm, and the maximum weight of workpiece can be processed is 5 kilogram.

GRINTIMATE PRECISION INDUSTRY CO., LTD.

Product Description :

a.Equipped with the exclusive hydrostatic spindle.

b.Equipped with the exclusive hydrostatic guideway .

c.The grinding wheel can be widened to 300mm with one-feeding grinding.

d.Headstock and tailstock both work with double sided synchronous.

e.Our products are on hundred percent designed and manufactured in Taiwan. To guarantee the stability of machine, all of the cast components go through a pressure relieve process

PALMARY MACHINERY CO., LTD.

Product Description :

For various eccentric circle or non-round shape workpieces grinding purpose, PALMARY develop CNC Cylindrical Grinder Cam Type with CAD/CAM software for easily transfer from workpiece drawing to grinding program. The workhead could offer precise angle control upto 0.1 micron resolution due to the C axis has accurate angle encoder. The infeed axis is driven by linear motor with linear guideway & close loop linear scale, it could avoid the backlash in order to reach high machining precision. Also, it could prevent the reaction force causing by linear motor under the large acceleration and deceleration motion, it could stabilize the grinding process.

KO-YAN PRECISE MACHINERY CO.,LTD

Product Description :

GO-356 CNC Cylindrical Grinding machine combines plunge feed grinding angular feed grinding in one with high investment efficiency. The GO-356 exhibits extraordinary machining accuracy with circularity reaching 0.8 um. It is compactly constructed, occupying a small floor area. Outstanding machine features also include high efficiency, high precision and high productivity.

Machine Features

-Plunge and angular feed grinding.

-Highly rigid machine structure ensures the best possible stability during grinding.

-X, Z-axis are designed with ¡¨V¡¨ and flat slideways.

-Equipped with DITTEL audio sensor for monitoring the grinding quality.

-The tailstock has air floating function.

-Helical grinding and non-circular grinding (optional).

-Grinding speed can reach 50

m/min.

-Circularity accuracy: 0.8 um.

-This machine is equipped with a FANUC Oi-TF CNC controller.

-Selection of various parts loading / unloading devices (optional).

-Measurement system on machine (optional).

-Automatic balancing system can display the unbalanced condition of grinding wheel (optional).

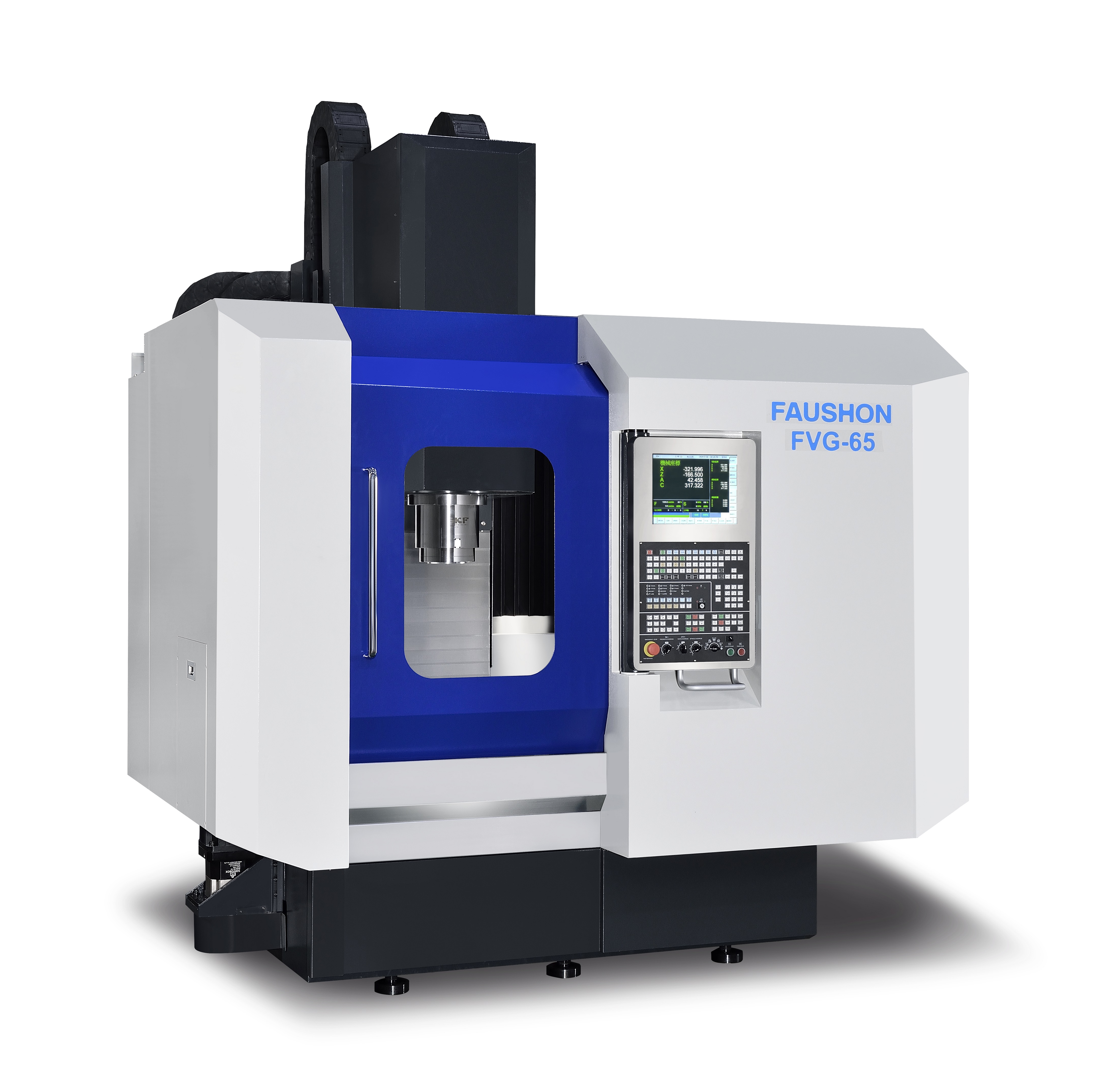

Fulson Industrial Co., Ltd

Product Description :

This model is the culmination of years of careful research and development by Faushon. It boasts a sturdy exterior and robust structure, with all operating handles and active control panels designed to be within the operator's optimal range and most comfortable operating position. This design adheres to ergonomic principles, providing you with higher work efficiency.

With our extensive experience in professional grinder manufacturing, we never compromise on accuracy. We can assure you that our machines offer high precision and reliability. We provide a variety of options and solutions to help address on-site challenges. Our machines are capable of multitasking and offer a high cost-performance ratio in terms of accuracy. The main structure design of the machine undergoes thorough finite element analysis and rigorous review of key components to achieve high precision and reliability.