Theme

Digital Transformation

Green Transformation

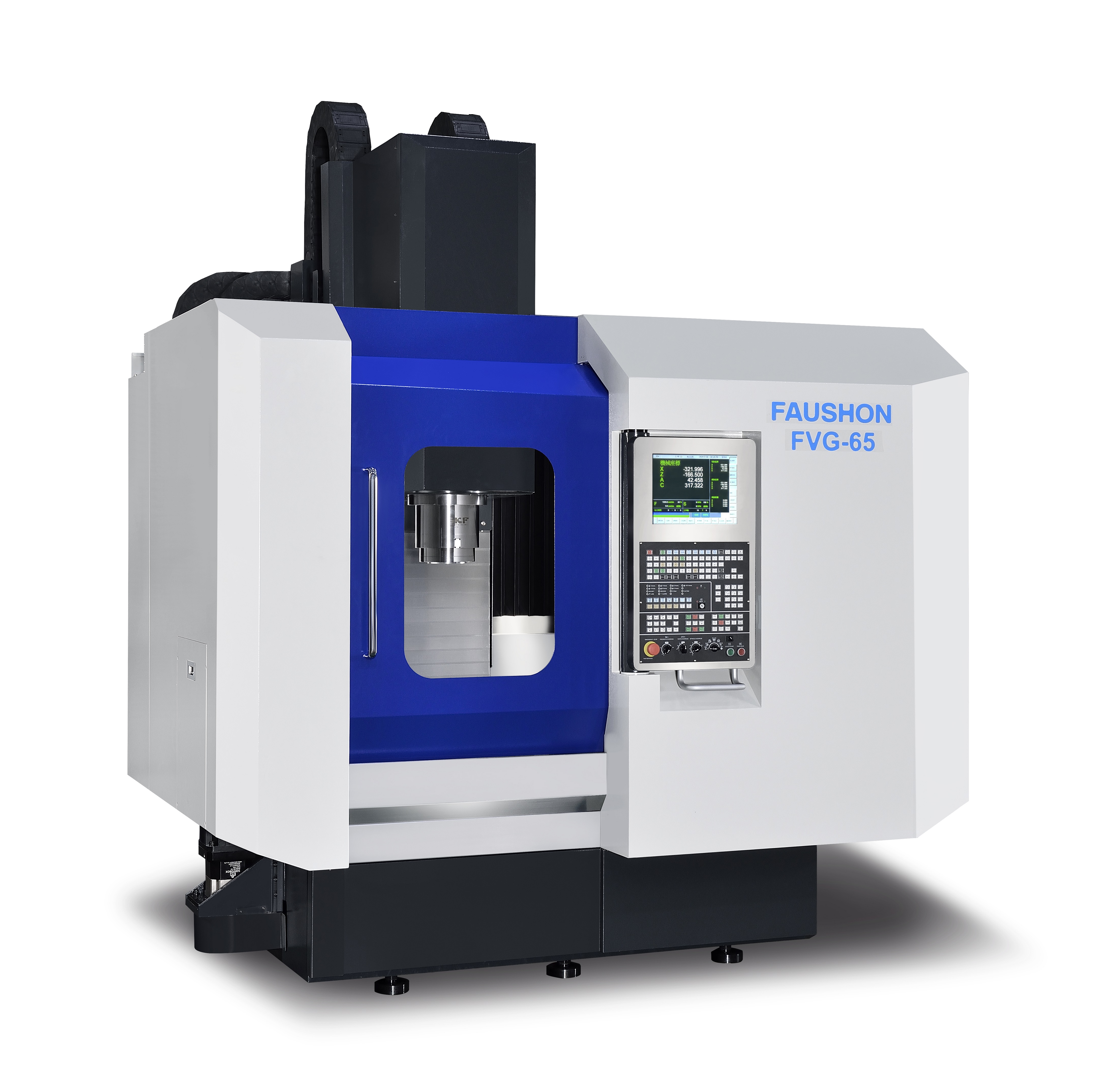

Fulson Industrial Co., Ltd

Product Description :

This model is the culmination of years of careful research and development by Faushon. It boasts a sturdy exterior and robust structure, with all operating handles and active control panels designed to be within the operator's optimal range and most comfortable operating position. This design adheres to ergonomic principles, providing you with higher work efficiency.

With our extensive experience in professional grinder manufacturing, we never compromise on accuracy. We can assure you that our machines offer high precision and reliability. We provide a variety of options and solutions to help address on-site challenges. Our machines are capable of multitasking and offer a high cost-performance ratio in terms of accuracy. The main structure design of the machine undergoes thorough finite element analysis and rigorous review of key components to achieve high precision and reliability.

PROTH INDUSTRIAL CO., LTD.

Product Description :

1.A : Auto-cross H : Hydraulic longitudinal R : Rapid up/down.

2.Overall architecture (horizontal module) : Overall structural design optimization /lightweight/stiffness strengthen.

3.Built-in spindle (15HP) with 20 inches grinding wheel.

4.Workpiece shape : flat grinding/step/plunge grinding.

5.Machine drive : Cross and vertical liner guide way, longitudinal double V guide way.

PROTH INDUSTRIAL CO., LTD.

Product Description :

1.Cross feed and vertical feed are driven by servo motors.

2.Horizontal spindle head,vertical spindle head(optional).

3.Double column construction and extra large diameter of rotary table.

4.The rotary table running is driven by a powerful motor and controlled by frequency inverter.

5.Two axes are servo controlled.

HYPERMAX MACHINERY CO., LTD.

Product Description :

1μ control-setting system and a design of high-rigidity roller rail track enhance the precision of locating axis. Also, JG1 integrates multiple processes, one chucking then inner face, bore and end face, into full grinding processes. Its powerful working capability completes a serial of 8 procedures at one time.

JEFFER MACHINERY CO., LTD.

Product Description :

JF-40S is a universal grinder with accuracy grinding technology. It can grind variety of woodworking knife tools, such as woodworking grooving cutter, shank router bit, finger jointer cutter and so on.

On the other hand, 40S is the most important metalworking machining machine tool which can grind knife tools used by Lathe and milling machine, if you need grind variety of machining metalworking knife tools, 40S is the best choice. JF-40S is a precise grinder with multifunction capability and also owns attractive pricing. Besides, JF-40S owns unique function that it is indispensable for broaching machine knife tools.

In addition to JF-40S, we do have JF-60S, JF-150S that is adjusted available on request.

GRINTIMATE PRECISION INDUSTRY CO., LTD.

Product Description :

a.Equipped with the exclusive hydrostatic spindle.

b.Equipped with the exclusive hydrostatic guideway .

c.The grinding wheel can be widened to 300mm with one-feeding grinding.

d.Headstock and tailstock both work with double sided synchronous.

e.Our products are on hundred percent designed and manufactured in Taiwan. To guarantee the stability of machine, all of the cast components go through a pressure relieve process

FALCON MACHINE TOOLS CO., LTD.

Product Description :

These words describe the driving forces behind the design of our SMART-IV CNC surface grinding machines. They’re the standards required by the medical, automotive, mining, semiconductor, aerospace, injection mold making and job shop industries in order to meet current and future market needs and pave the way to factory automation.

This series is capable of producing complicated shapes for highly accurate workpieces along with finer finishes. The heavy-duty slide rails, one-piece base casting and hardened wheelhead guideways create a solid, rigid machine structure that minimizes vibration, movement and displacement.

Chevalier’s user-friendly grinding machines include our exclusive PC-based SMART iControl featuring conversational programming.

Combined with TaskLink, it allows operators to create their own programs for generating complex grinding tasks in a single cycle—without an engineering degree.

TAIWAN MORE-CASH VILLAGE CORP.

Product Description :

For 2mm-13mm Twist Drill Re-sharpening , Angle 90°-140°

For 3mm-12mm End Mill Re-sharpening

Twist Drill:

1. Precise Grinding Results , Precision Assurance within 0.02mm

2. Easy to Operate , grinding a drill within 10 seconds.

End Mill

1. Adjustable Cutting Face Angle and Width

2. Easy to Operate , grinding a End Mill within 60 seconds.

Special Design High Accuracy Alloy Steel Collets

Accurate Grinding consumption 0.2mm

High Efficiency DC motor

Stable Quality Diamond Dust Grinding Wheel

Considerable Design, Invisible Tool Box, Delicate & Friendly Use

Portable Design with only weight 14.2 kgs.

FALCON MACHINE TOOLS CO., LTD.

Product Description :

Easy Setup, Flexible and Sealed for Grinding

The FVGC Series of vertical grinding machines is another prime example of Chevalier's position as the global leader in grinding technology. The series seamlessly increases efficiency and productivity for such industries as semiconductor, punch and aerospace, as well as other sectors for which these machines can be equipped. Workpieces in these fields primarily are a composite, single crystal silicon or brittle, along with other materials that present process challenges.