Theme

Digital Transformation

Green Transformation

KO-YAN PRECISE MACHINERY CO.,LTD

Product Description :

GO-356 CNC Cylindrical Grinding machine combines plunge feed grinding angular feed grinding in one with high investment efficiency. The GO-356 exhibits extraordinary machining accuracy with circularity reaching 0.8 um. It is compactly constructed, occupying a small floor area. Outstanding machine features also include high efficiency, high precision and high productivity.

Machine Features

-Plunge and angular feed grinding.

-Highly rigid machine structure ensures the best possible stability during grinding.

-X, Z-axis are designed with ¡¨V¡¨ and flat slideways.

-Equipped with DITTEL audio sensor for monitoring the grinding quality.

-The tailstock has air floating function.

-Helical grinding and non-circular grinding (optional).

-Grinding speed can reach 50

m/min.

-Circularity accuracy: 0.8 um.

-This machine is equipped with a FANUC Oi-TF CNC controller.

-Selection of various parts loading / unloading devices (optional).

-Measurement system on machine (optional).

-Automatic balancing system can display the unbalanced condition of grinding wheel (optional).

PALMARY MACHINERY CO., LTD.

Product Description :

Based on PALMARY's tradition of "Pursuing Quality Perfection", combined with human engineering design and peak performance concepts, each machine fully reflects PALMARY's unmatched design and technique.

Honeycomb type machine structure assures the best possible rigidity and stability. The machine bed is manufactured from high-quality Meehanite cast iron, heat treated and stress relieved for outstanding stability and without deformaiton.

FALCON MACHINE TOOLS CO., LTD.

Product Description :

Easy Setup, Flexible and Sealed for Grinding

The FVGC Series of vertical grinding machines is another prime example of Chevalier's position as the global leader in grinding technology. The series seamlessly increases efficiency and productivity for such industries as semiconductor, punch and aerospace, as well as other sectors for which these machines can be equipped. Workpieces in these fields primarily are a composite, single crystal silicon or brittle, along with other materials that present process challenges.

HC FENG CO., LTD.

Product Description :

Replenishing Fluid automatically, accurate cutting fluid concentration. One equipment to multiple CNC machining centers. The supply line can be as long as 20 meters.

#Filtration by 3 filters #Sterilization by ozone # Oil-water mixer to precise mixing 0-10% cutting fluid #Stirring device avoid cutting fluid become stagnant water. #oil tank level meter for 50 gallon barrel low level detection.

JEFFER MACHINERY CO., LTD.

Product Description :

JF-1600 Automatic Knife Grinder (wheel moveable version) is for grinding long and straight knives. For example, paper cutting knife, single side cutting knife, veneer cutting knife, planer knife and etc. Standard machine is for grinding straight knife length up to 1600mm. We could also extend this machine to grind straight knife length up to 2100mm. With user-friendly electronic control, it lets the operator as using it as enjoying it.

JF-1600 Feature :

1. Can obtain good, sharp knives by using a fine grinding wheel after a rough one.

2. Force cooling system gets knives neither heated, transfigured nor annealed.

3. Grinding wheel back-front movement with ball screw sets which obtain accurate and best result.

4. With magnetic chuck parallelism ± 0.02mm and high accuracy.

5. Equipped with variable speed motor for fine grinding wheel to grind high speed steel knives and carbide knives.

6. Splash guard and coolant tank are stainless steel.

7. Grinding capacity (LxWxT):1600x153x19mm

8. Fixed cutter by Magnetic Chuck.

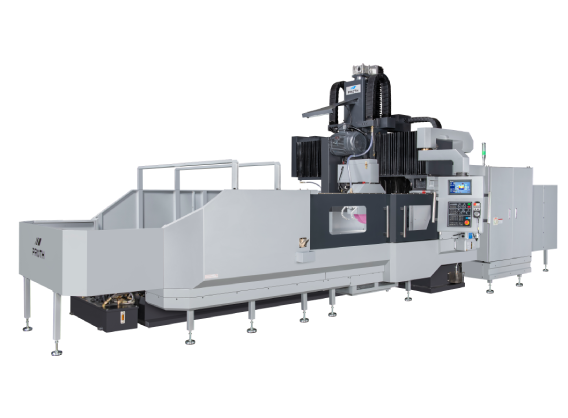

PROTH INDUSTRIAL CO., LTD.

Product Description :

1.A : Auto-cross H : Hydraulic longitudinal R : Rapid up/down.

2.Hydraulic System : Two single-acting hydraulic cylinders are used with their piston rods anchored at very specific positions.This enhances rigidity and creates a very stable table motion; table float is eliminated.

3. Grinding spindle : The precision high rigidity spindle is of a cartridge type design. This provides for easier accessibility and service when maintain is needed.

4. Upgradable CNC numerical control.

YOUN JIN ENTERPRISE CO., LTD.

Product Description :

DRILL GRINDING MACHINE

YD313 GRINDING RANGE 3~13 /

YD1226 GRINDING RANGE 12~26 /

YD0832 GRINDING RANGE 8~32 /

Standard accessories :

CBN WHEEL,Collets. Collets Holder .Cleaning Knob . Front Angle adjusting screw.

Optional Accessories:

Diamond Grinding Wheel SDC

PALMARY MACHINERY CO., LTD.

Product Description :

High grinding accuracy and high rigidity design for 4 axes CNC Centerless Grinder bearing spindle type.

Double-side slides design allows to equip the infeed grinding type device, also could arrange the optional high speed auto loading & unloading attachment.

The best configuration for machine bed and structural support ribs makes the grinding accuracies has high stability.

The customs design loading device and outer diameter measuring device are also possible as optional for best functional performance.

The grinding wheel spindle single bearing holding type equipped with super precision cylindrical roller bearings for the highest rigidity requirement.

The two slides design centerless grinder is suitable for long bar outer diameter grinding application.

The advantages include the work rest fixed in the machine which enable better grinding accuracies for its stability.