Theme

Digital Transformation

Green Transformation

Fulson Industrial Co., Ltd

Product Description :

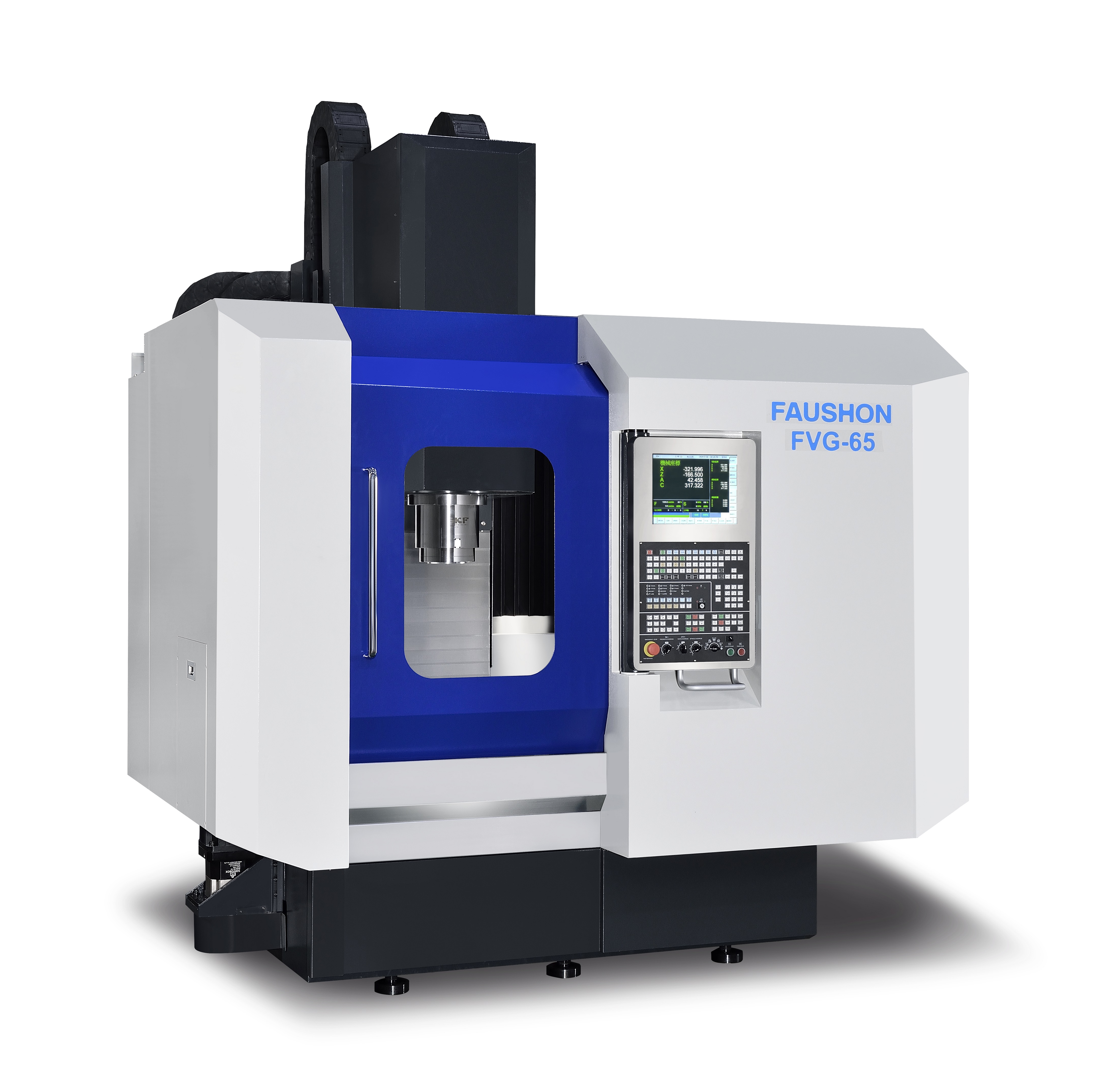

This model is the culmination of years of careful research and development by Faushon. It boasts a sturdy exterior and robust structure, with all operating handles and active control panels designed to be within the operator's optimal range and most comfortable operating position. This design adheres to ergonomic principles, providing you with higher work efficiency.

With our extensive experience in professional grinder manufacturing, we never compromise on accuracy. We can assure you that our machines offer high precision and reliability. We provide a variety of options and solutions to help address on-site challenges. Our machines are capable of multitasking and offer a high cost-performance ratio in terms of accuracy. The main structure design of the machine undergoes thorough finite element analysis and rigorous review of key components to achieve high precision and reliability.

Fulson Industrial Co., Ltd

Product Description :

This machine is the crystallization of the technology that Fushun has carefully researched for many years. It has a stable appearance and a strong structure. Various operating handles and movable operating panels are within the operator's best line of sight and the most comfortable operating position. This is in line with the ergonomic design. Excellent models, providing you with higher work efficiency.

Spindle mechanism: The spindle is supported by five ultra-precision beveled ball bearings. Stable and strong main shaft structure, can withstand heavy load grinding.

AC servo motor lift drive: C3-level drive screw, driven by AC servo motor, with large torque, fast speed, and high positioning accuracy. With the full CNC system, the feed accuracy can reach 0.0001mm or 0.001mm.

Two lines and one hard track: Z-axis and Y-axis purchase high-precision line rails, and cooperate with high-precision ball screws, which can make the action smooth without lag; , maintaining accuracy without distortion.

Front and rear transmission speed control: The continuous movement speed of the saddle is driven by AC servo motor to obtain good surface grinding accuracy.

FALCON MACHINE TOOLS CO., LTD.

Product Description :

Easy Setup, Flexible and Sealed for Grinding

The FVGC Series of vertical grinding machines is another prime example of Chevalier's position as the global leader in grinding technology. The series seamlessly increases efficiency and productivity for such industries as semiconductor, punch and aerospace, as well as other sectors for which these machines can be equipped. Workpieces in these fields primarily are a composite, single crystal silicon or brittle, along with other materials that present process challenges.

HC FENG CO., LTD.

Product Description :

The combination of centrifugal device and magnetic separator is perfect for processing water-and oil-based cutting fluids and sludge containing magnetic dusts and shavings. The shaving removal is quick and effective, which saves a lot of time waiting and minimizes the costs to replace consumables.

USYNC INC.

Product Description :

a. Through UE80CG, easy to operate.

b. It's flexibility.Not only use UE80CG but also use original G code on Mitsubishi controller.

c. Quickly set coordinate on "Easy set" function, it can reduce error form human operation.

d. It doesn't use G code to edit wheel's sharp,use drawing type to edit wheel's sharp.

FALCON MACHINE TOOLS CO., LTD.

Product Description :

These words describe the driving forces behind the design of our SMART-IV CNC surface grinding machines. They’re the standards required by the medical, automotive, mining, semiconductor, aerospace, injection mold making and job shop industries in order to meet current and future market needs and pave the way to factory automation.

This series is capable of producing complicated shapes for highly accurate workpieces along with finer finishes. The heavy-duty slide rails, one-piece base casting and hardened wheelhead guideways create a solid, rigid machine structure that minimizes vibration, movement and displacement.

Chevalier’s user-friendly grinding machines include our exclusive PC-based SMART iControl featuring conversational programming.

Combined with TaskLink, it allows operators to create their own programs for generating complex grinding tasks in a single cycle—without an engineering degree.

HC FENG CO., LTD.

Product Description :

4 in 1 Coolant Purification System

1. Filtering floating debris and dirty particles

2. Oil/Water Separation, removes tramp oil down to 5% water content

3. Ozone Disinfection, eliminates bacteria and cleaned fluid backflow

4. Automatic control panel and pH detect device

JAINNHER MACHINE CO., LTD.

Product Description :

JHD-3205CNC is for internal/external grinding. The Maximum grinding O.D. is 320mm and grinding O.D. length is 200mm. The range of I.D.grinding is 2~200mm and maximum grinding depth is 150mm. One piece fabricated base, high rigidity box type structure.3Axes feeding system adopts high precision roller linear guide-way and double pre-tensioned ball screws.All sliding and rotating parts use automatic forced lubrication to ensure accuracy and longer use life of machine. The work head can do manual swing. The B and X axis are also applicable for taper grinding.

JHD-3205CNC is suitable for the parts which need high precision and complicated grinding requirements. The application such as:automobile/motor /energy & machine tool components/ Air & hydraulic components/measuring instruments/electronic parts and optical instruments.

KO-YAN PRECISE MACHINERY CO.,LTD

Product Description :

GJ-400 series from COMIRK combines internal grinding and cylindrical grinding in a single machine. Multiple face grinding can be accomplished with one setup for the work-piece. This machine not only saves considerable amount on machine investment costs and labor costs, but it also features dramatically upgrade for better machining efficiency and machining accuracy.

Machine Features

-Various speed of spindles selection allows for the highest grinding efficiency

-Double wheel spindles exhibit high efficiency internal and external grinding

-Internal, external, end face and tapered face can all be ground in one process

-Highly rigid machine structure ensures the best possible stability during grinding

-X, Y, Z axes are all mounted with high precision linear guide-ways.

-This machine is equipped with a FANUC CNC controller

-Multi-face grinding requires only one setup for the work-piece.

-Non-circular grinding function is available (Optional)

-Fully enclosed splash-guard

PALMARY MACHINERY CO., LTD.

Product Description :

The new CNC internal Grinding Machine from PALMARY features optimal structural design, and an elegant appearance combined with advanced CNC control. The all new series will bring internal grinding technology into a new era. The structural parts of the machine are manufactured from high quality cast iron for deformation-free performance year after year. The entire machine is precision built throughout to guarantee the best possible grinding accuracy you can find anywhere.

PROTH INDUSTRIAL CO., LTD.

Product Description :

1.A : Auto-cross H : Hydraulic longitudinal R : Rapid up/down.

2.Overall architecture (horizontal module) : Overall structural design optimization /lightweight/stiffness strengthen.

3.Built-in spindle (15HP) with 20 inches grinding wheel.

4.Workpiece shape : flat grinding/step/plunge grinding.

5.Machine drive : Cross and vertical liner guide way, longitudinal double V guide way.