Theme

Digital Transformation

Green Transformation

LNC TECHNOLOGY CO., LTD.

Product Description :

• 7” touch screen

‧EtherCAT protocol provides high flexibility of peripheral equipment connection control

• All-in-one design: pendant integrated with control unit

• IP65 waterproof and dustproof protection

• Magnetic back fixing bracket

• Electronic hand-wheel design to machine tuning, facilitate adjustment and program dry run

• Support multiple types of robots: Six-axis, Delta SCARA or customized special type robots.

• Axis control: six-axis(for robot itself) and additional three axes (for external accessories)

• Application: Polishing robot, spraying robot, welding robot, handling/palletizing robot

G-TECH INSTRUMENTS INC.

Product Description :

A rotor that does not perform dynamic balance correction may produce unnecessary vibrations and thus reduce the productivity of the machine, as well as damage to the bearings. At the same time, it may cause damage to the outer frame or supporting device and foundation during severe movement.

G-Tech HJ-4250S-A Hard Bearing Balancing Machine is applicable for tool machine spindles, high-speed built-in spindles, motor rotors / motors, rollers, fans, centerless grinding wheels.

A maximum rotor weight of 500kg, a maximum rotor diameter of 1 meter, and measurement accuracy at low speed dynamic balance is 0.5gram-mm(max), and the can be 0.05gram-mm(max) at high-speed dynamic balance.

G-TECH INSTRUMENTS INC.

Product Description :

★Multi-Channel Dynamic Measurement: 4-CH simultaneous analog input, compatible to accelerometer, microphone, etc.

★Digital Data Processing: Local real-time computing, data storage, and transmit to data center via ethernet.

★Test & Measurement : Remote Mode--FFT Analyzer;Standalone Mode--Data Recorder & Transmitter.

★Condition Monitoring: Programable multiple I/O interface, connect to controller for intelligent manufacture.

SHENG FENG TECHNOLOGY CO.,LTD

Product Description :

Cross roller bearings consist of inner rings, outer rings, spacer retainers and cylindrical rollers cross arranged on the V-shaped 90° groove between the inner and outer rings. This structure can withstand radial, axial and moment loads in all directions because the rollers'line contact with raceway surfaces achieve a large load-bearing area despite the minimum dimensions. Therefore these bearings are widely used on the rotating parts of industrial robots, machine tools, precision rotary tables, measuring instruments and IC manufacturing machines.

Cross Roller Bearing Features:

High rigidity

Large load capacity

High rotation accuracy

Compactness

Easy to install and handle

G-TECH INSTRUMENTS INC.

Product Description :

The performance of the spindle is an important key to processing quality. When you understand the performance of the spindle, you can predict and control the quality of the processed parts. The shape accuracy, roundness, and surface roughness of the workpieces are all related to the performance of the spindle. Only when the spindle is real measuring the accuracy of the spindle at the processing speed of the machine has meaning to the control of the quality of the processed parts, so measuring and understanding the performance of the machine tool, finding the best working speed, determining the warm-up time, even confirm the accuracy of the spindle after the collision.

LION provided this SEA analysis system as early as 1993 to help spindle manufacturers, machine tool factories and processing plants to reduce workpiece defect rate and improve product quality.

★The SEA system complies with the following international standards:

✓ ANSI / ASME B5.54-2005: "Methods for Performance Evaluation of CNC Machining Centers"

✓ ISO230: Test Code for Machine Tools, 3: "Determination of Thermal Effects" 7: "Geometric Accuracy of Axes of Rotation"

✓ ANSI / ASME B5.57-1998: "Methods for Performance Evaluation of CNC Turning Centers"

✓ ANSI / ASME B89.3.4: "Axes of Rotation, Methods for Specifying and Testing"

COMETECH TESTING MACHINES CO., LTD.

Product Description :

If you are looking for a low-cost but with great function performance motor driver, then the C2A series will be a great bargain. This series is suitable for motors below 150W, and the small size occupies no space. Besides adjusting the motor speed, users can set up detailed motor-related data settings with our C2 series driver. Its multifunctional integrated design is the main feature and advantage for saving costs and reducing external components.

Users can connect directly to the dedicated software for easy parameter tuning and configuration with the built-in Wi-Fi module. An over-the-air firmware update without assembling the driver from devices can improve maintenance efficiency and convenience.

Moreover, the driver features a modular expansion design that allows flexible extensions of communication formats, wireless screen modules, and more to meet various user needs.

※Specification

-Rated Voltage: DC 12~48V

-Rated Output: 150W

-Rated Current: 7.5A

-Applicable Motor: BDC, BLDC

-Motor Feedback: Hall Sensor, Sensorless; Encoder input signal is available

-Communication Interface: Built-in Wi-Fi module and RS-485

-Speed Control: Analog input, Command sources

-Display: 2.8" wireless color touch screen for options

-Software: Equipped with dedicated motor monitoring software which is available to connect with mobile devices (smart phone, pad, notebook, etc.) through Wi-Fi.

※Features

-Compact size

-Integrate multiple functions to reduce the external components' cost

-Monitor the motor's status such as voltage, current, speed, etc. through dedicated software

-Data setting and devices' status monitoring by dedicated software through Wi-Fi connection

-Support different motor control modes (revolutions, distance, operation speed, etc.) and multi-step programmable settings

-Modbus-compatible driver for various host controllers.

-Over-the-air firmware update

-Multiple I/O (open collector) for flexible expansion of different applications

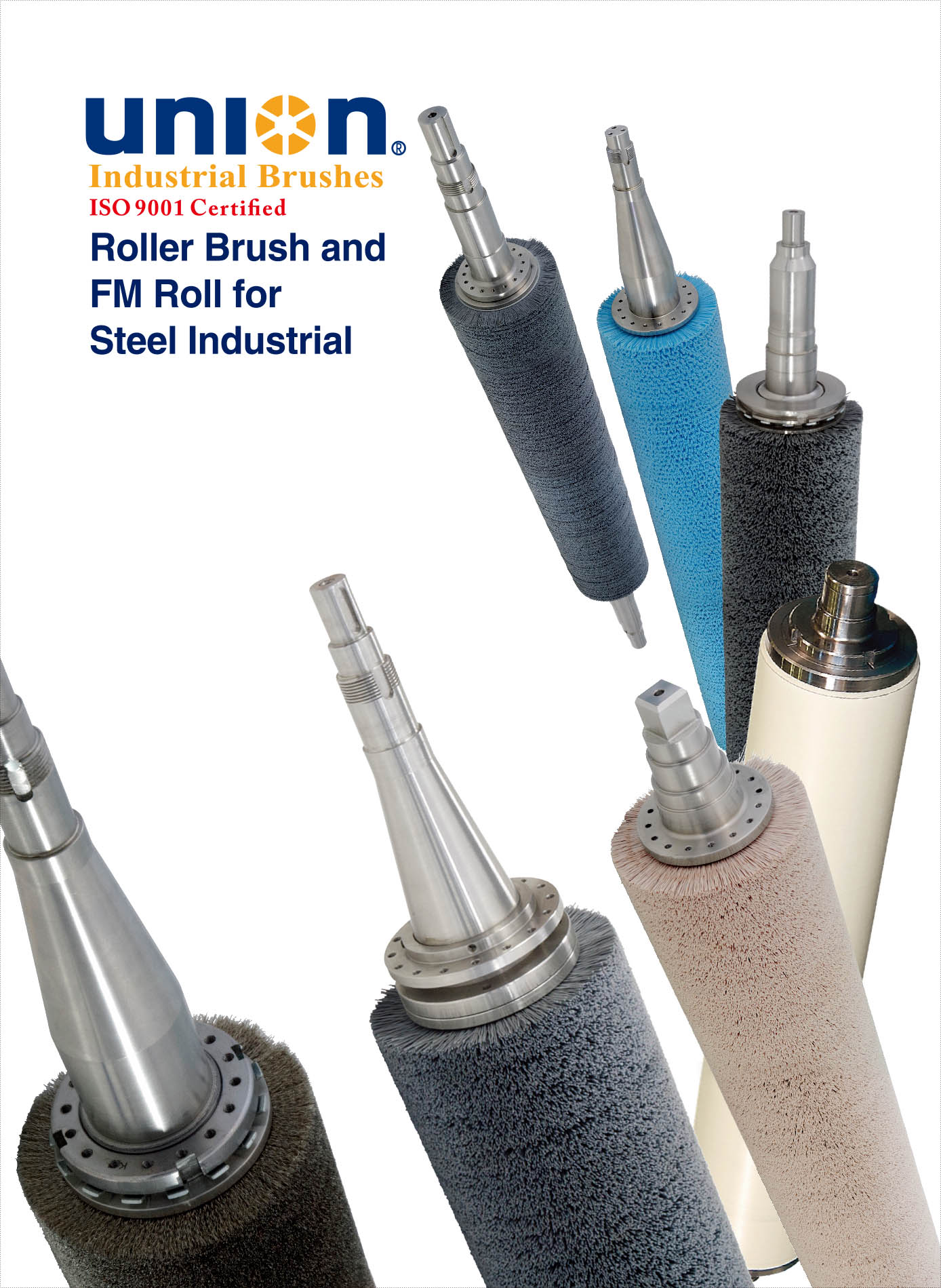

EANG LIAN CORPORATION

Product Description :

Steel industry, metal plates rolling production line, wire drawing production line and in processes such as acid pickling, degreasing and cleaning after annealing. Surface treatment such as brushing, grime removal, cleaning, etc. as part of large-scale equipment manufacturing processes for various types of automated production lines.

BORE AUTOMATION TECH. CO., LTD.

Product Description :

24V DC 16 Channels Relay Module, equipped with high qaulity OMRON G3DZ-DZ02P-DC24 SSR power relay, high quality WAGO PUSH-IN Type PCB terminal block, easy to replace pluggable relays, fully compatible with variety PLC /CNC controller, muti-functional protection , optimized installation effort

SESAME MOTOR CORP.

Product Description :

Sesame Motor has engaged in offering excellent quality planetary gearboxes, gearheads and gear reducers to our valuable clients for almost 30 years. Multiple designs, models, performance levels and customized motor brackets to offer different ranges of power transmission solutions. Precision gear design and processing incorporate one-piece planet gear carrier and output shaft to provide higher radial load, increased service life and low backlash.

Visit https://www.sesamemotor.com/products/en/

USYNC INC.

Product Description :

"VM25" is a high-performance application of a fully modular system designed for grinding machines, including automatic balancing on the 1 and 2 sides of the grinding wheel spindle, the use of audio detection to control the contact of the grinding wheel to the workpiece or sand, online Measurement and off-line measurement (absolute or relative) and other functions.

"B-Safe" can provide vibration and temperature information of the main shaft to detect and monitor the status analysis of the main shaft and machine. It is a new thinking product for intelligent monitoring. Its miniaturized volume design helps to install directly on the main shaft, ensuring that it can provide immediate monitoring of abnormal operating conditions, further predicting the timing of maintenance and failures, protecting your machine and reducing downtime.