Theme

Digital Transformation

Green Transformation

Administration for Digital Industries, moda

Product Description :

The customer is very interested in the product and wants to further cooperate with the company, but is unable to produce a quotation on the first line. Even if a quotation is produced, it still takes a lot of time and cost to communicate with the customer and notify the manufacturer of the manufacturing plan, which ultimately results in Limited profits to be made? i+Simple assists enterprises to establish close relationships with customers. It combines accurate valuation mechanisms with CRM+SCM to quickly generate quotations based on various costs, record customer needs, and after receiving customer orders, it is connected to SCM for production operations. Assist customers in a systematic manner to deliver orders on schedule. Meet various flexible business strategies, reduce the company's operating process time, obtain more orders, master internal and outsourced production line information, and improve company satisfaction.

CAMPRO PRECISION MACHINERY CO., LTD.

Product Description :

Campro spares no effort to develop intelligent manufacturing; fully demonstrating its determination from Industry 3.0 to 4.0, Campro not only has successfully launched CAMPRO IIoT system in line with Industry 4.0 elements in 2016, but also developed its CAMPRO Smart FMS system in 2018. Through flexible manufacturing system, digital control and automated NC program and machine assignment that it can quickly react in case of changes and respond to market demand. In addition, CAMPRO also develops, CAMPRO TOOLING MANAGEMENT SYSTEM, a proprietary system combined with precision tooling/material cabinet to assist customers in managing and analyzing tooling/material usage, 24 hours to get tools or materials and early-warning or alert notifications. In some cases, the fact is increasing automation can improve worker safety and the flexible automation processing is sufficient enough to cope with complex manufacturing processes.

ICOP Technology Inc.

Product Description :

DMP Embedded Mini PC series helps companies improve product quality and reliability, lower manufacturing costs with affordable price. EBOX Mini PC Series in 100 x 100mm and 75 x 75mm VESA Standard and DIN Rail designed, perfect platform for IoT, M2M, Industry 4.0, Home Automation, Security, Public transportation, Medical, Industrial controls, Point-of-Sales, kiosk, Thin Client, telecommunication, mobile surveillance, environmental monitoring, intelligent transportation systems, automated parking control systems and many other more.

Administration for Digital Industries, moda

Product Description :

Robotiive, developed by IsCoolLab, is a Robotic process automation (RPA) solution that utilizes patented AI computer vision technology to achieve cross-platform, cross-system, cross-machine, and remote desktop data extraction, integration and automation. It is the only RPA system in the market that integrates both manufacturing and office settings.

Using Robotiive, corporations can enhance productivity and efficiency but also substantially reduce human resource and operational costs. Additionally, its high scalability allows businesses to customize settings according to their own needs, providing their departments with a 24/7 digital workforce.

LNC TECHNOLOGY CO., LTD.

Product Description :

‧Provide control and development flexibility, quickly upgrade equipment to smart machines

‧Fourth/fifth-axis control ;provide up to 32-axis control via EtherCAT protocol

‧Optional RFID function for personnel authority and data control

‧Optional robot control function module, integrated robot control with tool machine to complete automation processing.

‧Connect to LNC smart vibration sensor, SVI1000/2000 to develop various smart value-added functions

‧Connect with video devices to develop image-related application functions, such as processing monitoring or positioning.

CIMer Tech co.,Ltd.

Product Description :

Distributed data management

Store, protect and deliver your most important messages

CIMer is a system specially built for the period from product development to mass production. From business orders, CAD product design, material creation, process review, and project management, it can be tracked and searched through any device. As long as you have a browser, you can Can participate in inspection and review of product design and development work.

system structure

Each region establishes its own Vault Server, and files will be synchronized between Vault Servers. Users can access the local Vault Server when accessing files. Users do not need to obtain the original CAD drawing files. CIMer provides converted graphics viewing formats (3D HTML/2D PDF), which can reduce the consumption of web page resources during viewing and improve transmission efficiency....

project management

Provide dynamic information on multi-project management at each stage during product development, such as Gantt charts, to assist the product development team in focusing on product development and improvement, and provide relevant timetables, human resources, output overview and distribution development periods during the period. , achieve better planning and utilization.

Design data and graphics management

Multi-CAD integration platforms, including drawing configuration, properties, versions, version management, combined drawing structures, parts and specifications/file associations of AutoCAD, zwCAD, Creo, Solidworks, Solid EDGE, Inventor, ZW 3D, NX, CATIA, etc., such as Approving documents, document version management, HTML format model viewing, 2D PDF document viewing, sharing drawings, BOM information based on design combination drawings...

Material Management Parts BOM/EC

After the product drawing design is completed, it enters the engineering proofing stage and related material information collection and management. Drawing files, material number correspondence, material attribute management, version management, association and viewing of materials and files, material BOM, automatic generation of material numbers, shared materials, etc...

Sign-off process management

Provide process system customization, and allow multiple people to collaboratively review all work that requires mutual notification, recognition, and review during the product development process. It is used at the review and notification level of the process and can be flexibly applied to the work processes of different departments and personnel.

Network collaboration

CIMer Web provides data viewing in non-Windows environments and implements the basic principles of ESG. Any device with a browser can participate in online process progress, such as inspection and review of product design and development work, paperless factory, post-engineering EC design change management from direct access of design drawings to manufacturing cells...

Message Center

Similar to the Outlook mail management function, it provides a message management center to manage notification messages, quickly jump from messages to related project work, and at the same time send emails to the mail server...

Over 20 years of experience in CIMe system development.

Over 300 case studies.

Visited more than 1,000 customer needs.

More than 200 customer satisfaction cases.

The CIMer system helps shorten your product time to market and significantly saves production costs and hidden losses.

Administration for Digital Industries, moda

Product Description :

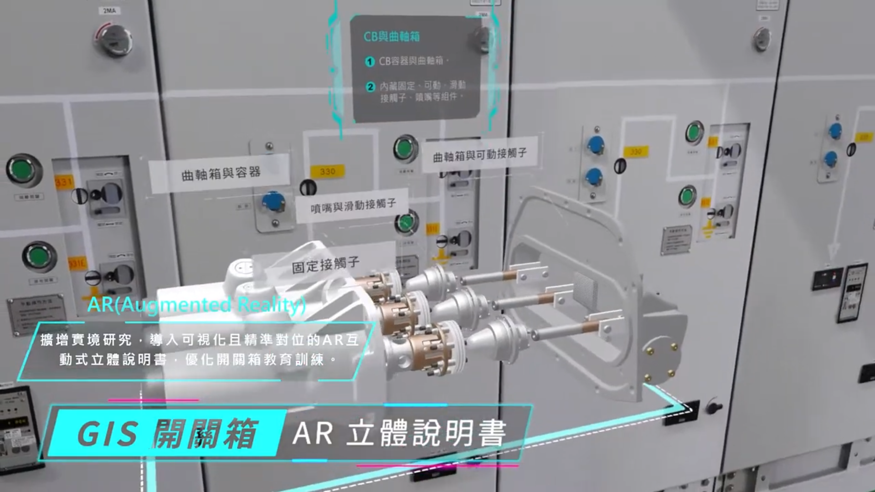

The Industrial XR SOP Solution""utilizes AR/VR/MR cross-platform integration technology to ensure seamless operation across various devices such as smartphones and head-mounted displays. It is specifically designed for the industrial sector as an XR intelligent carbon reduction integration platform service.

It's key features include support for ""cross-temporal"" information transmission and real-time monitoring, enabling precise and instant ""cross-span"" collaboration capabilities. Through the integration of virtual and augmented reality, information is transformed into a ""visualized"" presentation, allowing users to intuitively understand and operate, thereby assisting enterprises in effective resource management, reducing waste, and helping industrial production lines lower carbon footprints. This, in turn, improves energy efficiency and achieves a more environmentally friendly production model.

The application scope covers various stages of industrial production, including machine equipment, factory premises, vocational training, remote collaboration, maintenance and operation, and business showcases. Through comprehensive cross-platform integration technology, it provides intelligent, efficient, and eco-friendly solutions.

Administration for Digital Industries, moda

Product Description :

"Tukey is a No-Code AI platform designed to empower the manufacturing industry with AI solutions, assisting businesses in making optimal decisions in real-time. The key features of Tukey include user-friendly interfaces, easy scalability, and customizable development.

With a friendly operating interface, users can effortlessly create, adjust, and continuously manage AI models. Additionally, users can access custom dashboards through Tukey's extension modules.

Tukey excels in handling factory IoT data, ERP data, and CRM data. Through Tukey's drag-and-drop data extraction, automatic data preprocessing, and parameter adjustments, users can independently complete AI applications. After deploying their self-built artificial intelligence models, users can utilize Tukey's API to create their applications, such as integrating with BI tools or issuing anomaly notifications."