Theme

Digital Transformation

Green Transformation

DOWELL CO.,LTD.

Product Description :

ESPRIT® is a high-performance CAM system for CNC programming, optimization and simulation — supporting any class of CNC machine via one common user interface and workflow. Using a digital twin of the CNC to simplify the programming process, ESPRIT delivers edit-free G-code. Combined with ESPRIT's ability to solve workflow challenges with individually tailored automation solutions, ESPRIT is the smart manufacturing solution for any machining application.

With world-class technical support, ESPRIT empowers you to get started quickly and keep your shop running at top efficiency. ESPRIT is the only CAM system you’ll ever need.

REN AN INFORMATION TECHNOLOGY CO., LTD.

Product Description :

RenAn's operation simulation workstation is a physical simulation with 3D graphic, showing the cutting and machining process.

[Save consumable cost]: There is no need to worry about the expenditure of consumables, and it will not be affected by pollutants such as waste materials and oil and gas.

[Safety]: Advanced 3D simulation and CNC virtual machine make high risk CNC operation without any danger.

[Smart learning]: Like training the pilot using flight simulators, we use CNC simulator to train the students or operators to be the machinist. Its industrial panel remains the same functionality as real machine that students can practice constantly to accumulate hands-on operation skills.

The controller series of simulator: Fanuc, Siemens, Heidenhain and Mitsubishi.

Turning, Milling, TurnMill, 4 axis, 5 axis.

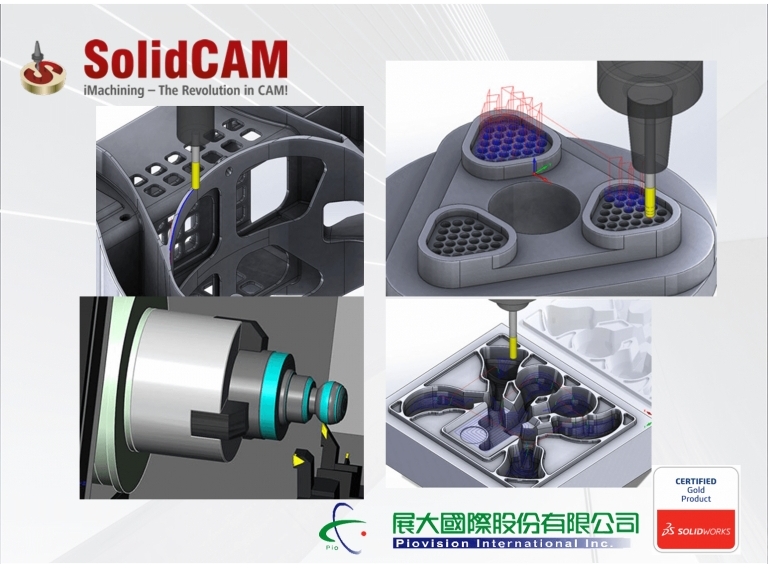

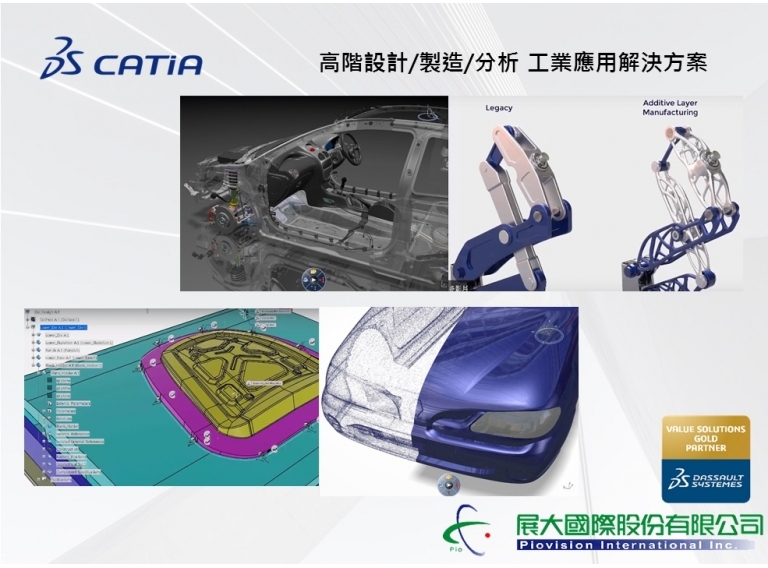

PIOVISION INTERNATIONAL INC.

Product Description :

CATIA強化您的開發與設計工作以全面符合客戶的高度要求,並提供3DEXPERIENCE平台,讓使用者可以簡易<br />

<br />

完成圖檔管理的工作。根據不同的產業別與需求,分別提供適合不同的模組套裝,例如:機械設計套組、逆向工程套<br />

<br />

組、模具設計套組、外型設計與自由曲面造型套組、工程分析套組...等。<br />

<br />

CATIA擁有強大曲面設計、逆向工程等功能,強化企業開發與設計工作效能,廣泛適用於航太、汽車、機械、電子等<br />

<br />

產業,可支援OEM到供應鏈製造商等。具備直觀的3D建模和模擬功能,同時深具包容性的產品開發平台,讓現有<br />

<br />

流程和工具輕鬆集成,採用一體化思路,讓您從設計到製造整合於一平台完成。

REN AN INFORMATION TECHNOLOGY CO., LTD.

Product Description :

Just like the real CNC machine, equipped with exactly same overall appearance, actual handwheel and real machine operation panel as numerical control machine.

Solving the difficulties of real machine: precise, complicated and very expensive.

With CNC Simulator, everyone can learn CNC machine operation and accumulate hands-on operation skills.

CNC training machine is equipped with exactly same overall appearance, actual handwheel and real machine

operation panel as numerical control machine. Its purpose is to train students for accumulating CNC machine operation skills (program transmission, programming, tool selection, tool compensation and alarm clear )

Overall design is more attractive, and it emphasizes on interaction to make students less mistakes happened.

Not only decreasing learning cost but also letting students work and learn in the safe environment.