Theme

Digital Transformation

Green Transformation

RAISE PRECISION CO., LTD.

Product Description :

The compact, high-resolution MiniCODERs have proven their value for speed and position acquisition in highly dynamic applications. They use their full potential when installation situations with little space require a particularly compact, robust and reliable measuring system. The magnetic measuring systems consist of a ferromagnetic target wheel and a scanning unit. Without dedicated bearings, they are completely wear-free and maintenance-free. The optimised circuit and screening technique, and fully encapsulated electronics ensure reliable operation even in harsh environments.

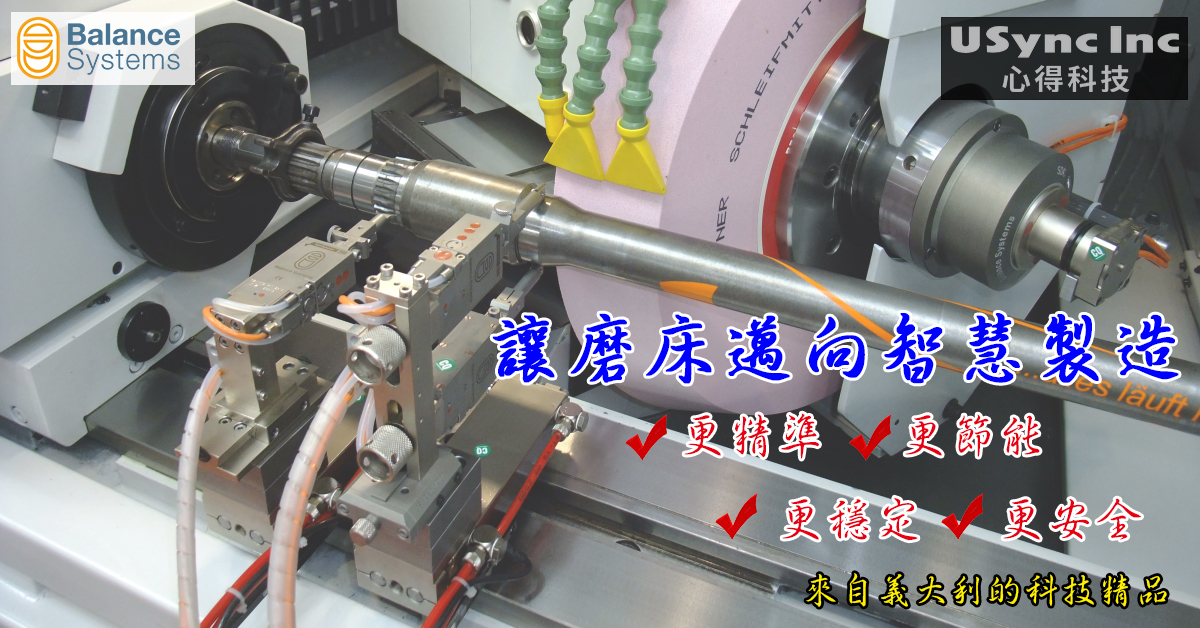

USYNC INC.

Product Description :

"VM25" is a high-performance application of a fully modular system designed for grinding machines, including automatic balancing on the 1 and 2 sides of the grinding wheel spindle, the use of audio detection to control the contact of the grinding wheel to the workpiece or sand, online Measurement and off-line measurement (absolute or relative) and other functions.

"B-Safe" can provide vibration and temperature information of the main shaft to detect and monitor the status analysis of the main shaft and machine. It is a new thinking product for intelligent monitoring. Its miniaturized volume design helps to install directly on the main shaft, ensuring that it can provide immediate monitoring of abnormal operating conditions, further predicting the timing of maintenance and failures, protecting your machine and reducing downtime.

BLUM PRODUCTION METROLOGY CO., LTD.

Product Description :

• Measuring speed up to 3 m/min

• Precise, non-lobing touch characteristics

• No-wear, optoelectronic measuring mechanism

• Use of two measuring systems with one IR receiver

• Extended battery life

• Precise measurement even with coolant

• Proven and robust design

Ametek Taiwan Corp., Ltd.

Product Description :

Autocollimator:The autocollimator is used for measuring angle, straightness, flatness, squareness and parallelism.

MAT:The micro alignment telescope is used for alignment inspection and adjustment in machine tool and ship industries.

Talyvel:The Talyvel electronic level is used for measurement and adjustment, such as: straightness of machine tool guideway, flatness of granite platform.

Clinometer:Precision in angular measurement, checking and setting with 360° range.

Prism Checker:Automatic Prism/Polygon measurement system.

G-TECH INSTRUMENTS INC.

Product Description :

The performance of the spindle is an important key to processing quality. When you understand the performance of the spindle, you can predict and control the quality of the processed parts. The shape accuracy, roundness, and surface roughness of the workpieces are all related to the performance of the spindle. Only when the spindle is real measuring the accuracy of the spindle at the processing speed of the machine has meaning to the control of the quality of the processed parts, so measuring and understanding the performance of the machine tool, finding the best working speed, determining the warm-up time, even confirm the accuracy of the spindle after the collision.

LION provided this SEA analysis system as early as 1993 to help spindle manufacturers, machine tool factories and processing plants to reduce workpiece defect rate and improve product quality.

★The SEA system complies with the following international standards:

✓ ANSI / ASME B5.54-2005: "Methods for Performance Evaluation of CNC Machining Centers"

✓ ISO230: Test Code for Machine Tools, 3: "Determination of Thermal Effects" 7: "Geometric Accuracy of Axes of Rotation"

✓ ANSI / ASME B5.57-1998: "Methods for Performance Evaluation of CNC Turning Centers"

✓ ANSI / ASME B89.3.4: "Axes of Rotation, Methods for Specifying and Testing"

G-TECH INSTRUMENTS INC.

Product Description :

★POSITION INSPECTOR: Quick health check of your machine tool linear axis

★POSITION ANALYZER: In-depth analysis & diagnostics of your machine tool linear axis

★ROTARY AXIS INSPECTOR: Quick health check of your machine tool rotary axis

★ROTARY AXIS ANALYZER: In-depth analysis & diagnostics of your machine tool rotary axis

★SPINDLE INSPECTOR: Quick health check of your spindle accuracy & performance

★SPINDLE ANALYZER: In-depth analysis & diagnostics of your spindle accuracy & performance

EQP SERIES CO., LTD

Product Description :

General-purpose, low-cost vibration sensor with an integrated sensor and amplifier, and an output current ranging from 4 to 20 mA. This low-cost and straightforward vibration monitoring sensor is ideal for controlling and monitoring rotating machinery. It offers three measurement modes: displacement measurement, velocity measurement, and acceleration measurement.

Due to the 4-20 mA DC output, it can be directly connected to recorders, displays, timing circuits, and other equipment. The integrated design of the sensor and amplifier eliminates the need for a separate vibration meter amplifier. It operates on a 2-wire system, comprising power and signal lines, with no polarity considerations during connection.

By connecting to a dedicated monitor or instrument relay, it can be used as a vibration meter or vibration measuring instrument. It is also compatible with Fuji Electric's MVM series.

※Can be used in conjunction with the Model-2590C display.

RAISE PRECISION CO., LTD.

Product Description :

CAPTRON is an experienced measuring technology manufacturer for the industry and the market leader in fill level measurement in the field of dispensing technology. Capacitive CAPTRON probes accurately and reliable measure the fill levels of liquids, bulky goods, pastes, adhesives and chemically aggressive materials.

With the CAPselect system for level sensors, you are able to freely configure the probe of your choice depending on the application, container type and sensor properties. CAPTRON produces these with millimetre accuracy to ensure full flexibility.

There are two systems to choose from: Compact probes, in which the electronics and probe form a single unit. Probes with external amplifiers that are suitable for applications with high temperatures and pressures.

Thanks to their wear-free electronics combined with high-quality material such as stainless steel, Teflon and Peek, CAPTRON level sensors are reliable, robust and long-lasting.