Theme

Digital Transformation

Green Transformation

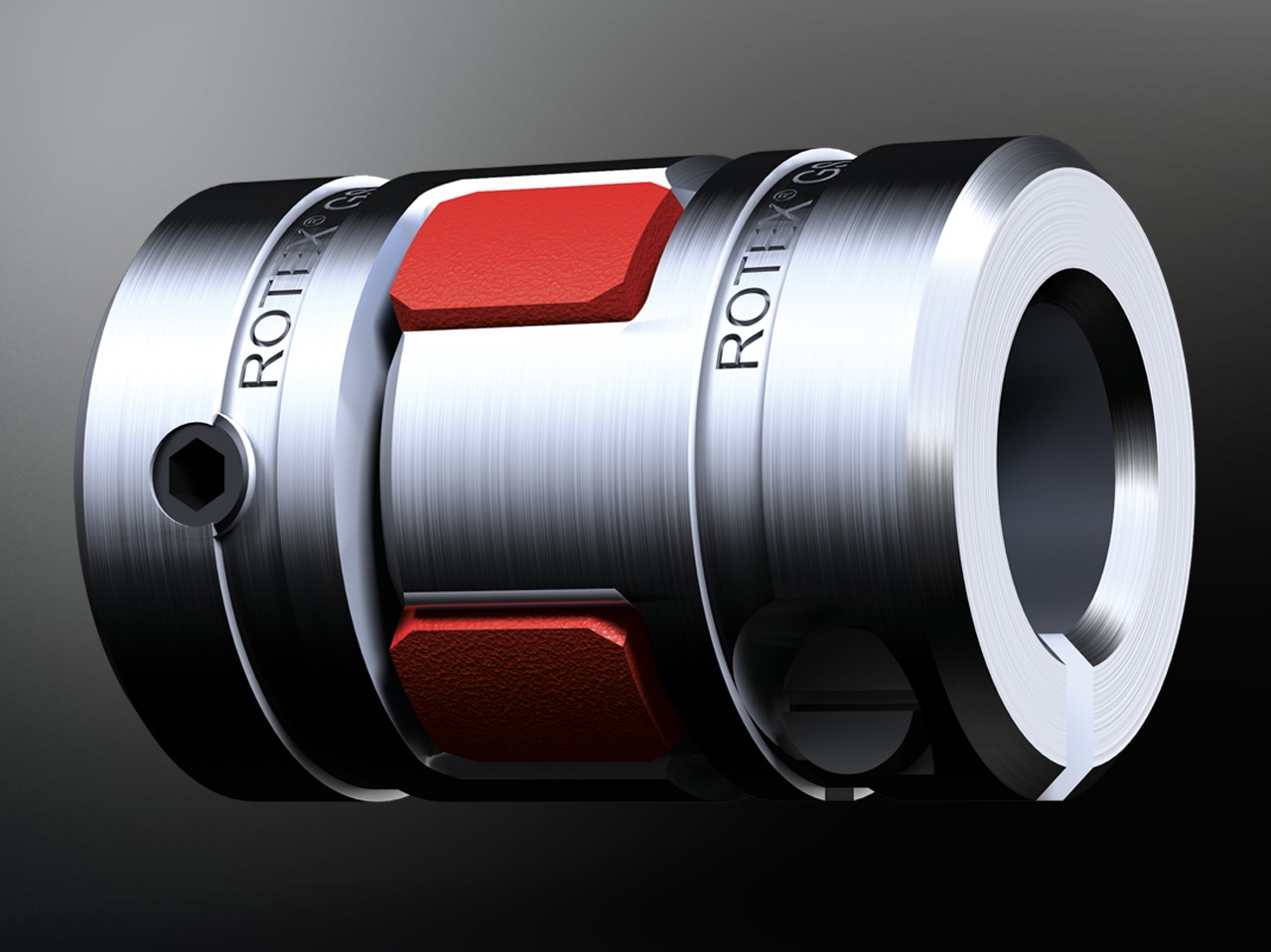

KTR TAIWAN LTD.

Product Description :

ROTEX® GS is a three-part coupling, backlash-free under pre-stress. The different hub designs and the different Shore hardnesses offer the optimal coupling for each application in automation engineering. In spite of its vibration-damping characteristics it is torsionally stiff so that it is not necessary to make any concessions to accuracy even with highly dynamic servo drives. The ROTEX GS works with the modular system; a high variety of different hub designs is available which can be combined within one coupling size.

G-TECH INSTRUMENTS INC.

Product Description :

A rotor that does not perform dynamic balance correction may produce unnecessary vibrations and thus reduce the productivity of the machine, as well as damage to the bearings. At the same time, it may cause damage to the outer frame or supporting device and foundation during severe movement.

G-Tech HJ-4250S-A Hard Bearing Balancing Machine is applicable for tool machine spindles, high-speed built-in spindles, motor rotors / motors, rollers, fans, centerless grinding wheels.

A maximum rotor weight of 500kg, a maximum rotor diameter of 1 meter, and measurement accuracy at low speed dynamic balance is 0.5gram-mm(max), and the can be 0.05gram-mm(max) at high-speed dynamic balance.

TES ELECTRICAL ELECTRONIC CORP.

Product Description :

FEATURE:

Six particle size channels : 0.3m, 0.5m, 1.0m, 2.0m, 5.0m, 10m

Integrated temperature / humidity sensor (no need for external add-on).

Flow rate 2.83 L/minute (0.1 CF / minute).

Rechargeable battery provides up to 4 hours of continuous operation (charge time 2.5 hours).

Buffer function allows storing and redisplay of up to 500 measurement data sets.

SD storage device.

APPLICATIONS:

Monitoring clean-rooms, manufacturing processes and pharmaceutical production.

Indoor Air Quality (IAQ) monitoring.

Monitoring gowning rooms.

Testing filter seals.

Locating particle contamination sources.

Monitoring particle size distributions.

ACROW MACHINERY MFG. CO., LTD.

Product Description :

Rotating Coolant Union / Grippers (Clamping unit)/ Pallet Clamping Systems / Test Bar / Force Gauge

TES ELECTRICAL ELECTRONIC CORP.

Product Description :

FEATURES

Automatic ferrous or non-ferrous substrate

material measurement

Non-magnetic coating on ferrous metal

substrate and insulating coating on

non-ferrous metal substrate measurement

Audible and visual warning when tolerance

limits are exceeded

Statistical display of significant values such as

mean value, standard deviation, min, max values

Units of measurement μm/mils select

LCD display with backlight

Auto power off

RAISE PRECISION CO., LTD.

Product Description :

CAPTRON is an experienced measuring technology manufacturer for the industry and the market leader in fill level measurement in the field of dispensing technology. Capacitive CAPTRON probes accurately and reliable measure the fill levels of liquids, bulky goods, pastes, adhesives and chemically aggressive materials.

With the CAPselect system for level sensors, you are able to freely configure the probe of your choice depending on the application, container type and sensor properties. CAPTRON produces these with millimetre accuracy to ensure full flexibility.

There are two systems to choose from: Compact probes, in which the electronics and probe form a single unit. Probes with external amplifiers that are suitable for applications with high temperatures and pressures.

Thanks to their wear-free electronics combined with high-quality material such as stainless steel, Teflon and Peek, CAPTRON level sensors are reliable, robust and long-lasting.

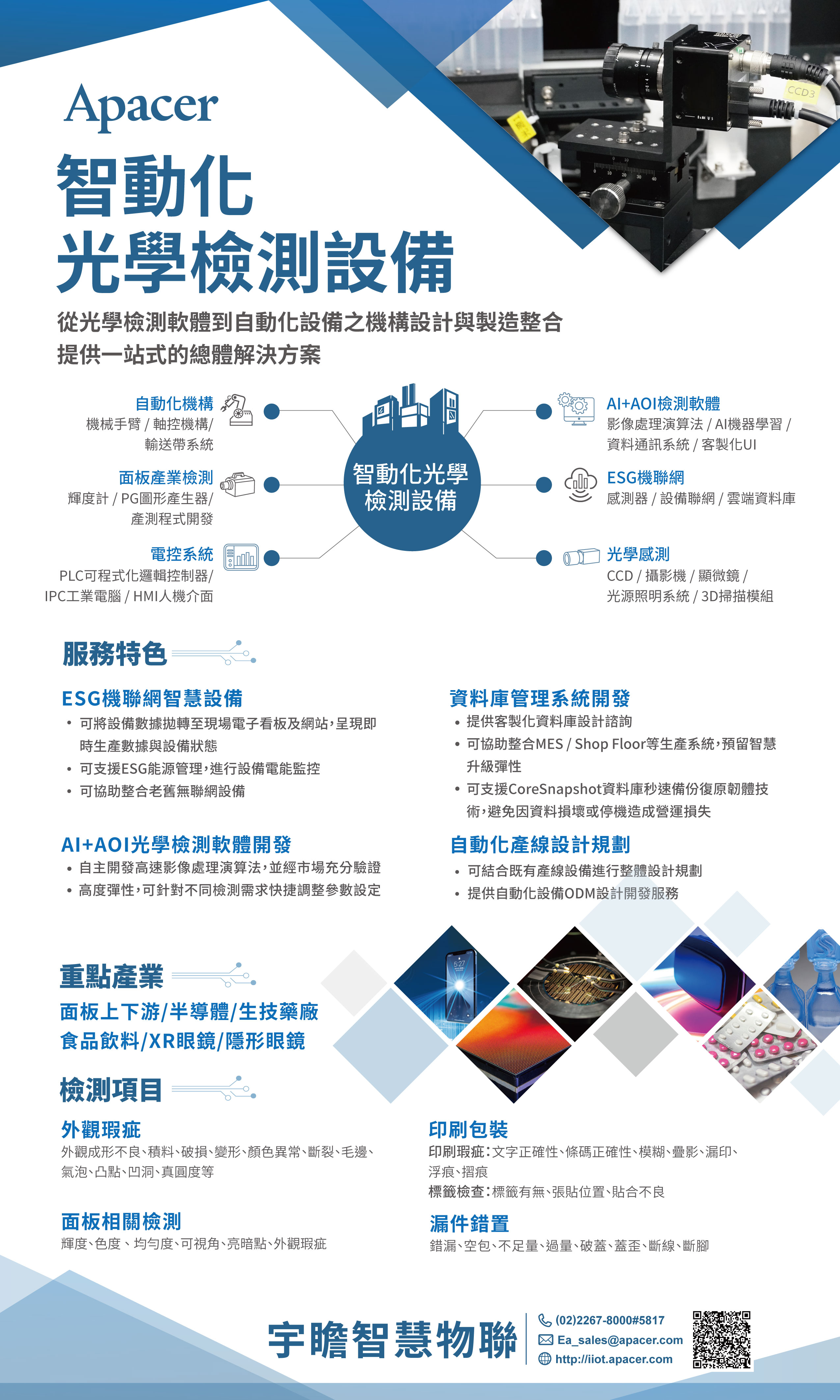

APACER TECHNOLOGY INC.

Product Description :

從光學檢測軟體到自動化設備之機構設計與製造整合

提供一站式的總體解決方案。

客製化規劃,專業設計開發AI+AOI光學檢測機台,可串連現有機台,設計全新自動化流程,提升瑕疵檢測的效率、降低人力成本。適用於面板業、生技藥廠、半導體、食品飲料等產業的各式瑕疵檢測應用。

瞭解更多:https://iiot.apacer.com/tw/optical-inspection/ai-aoi-automation/

更多實績案例,歡迎參考Apacer宇瞻智慧物聯官網:https://iiot.apacer.com/tw/case-studies/

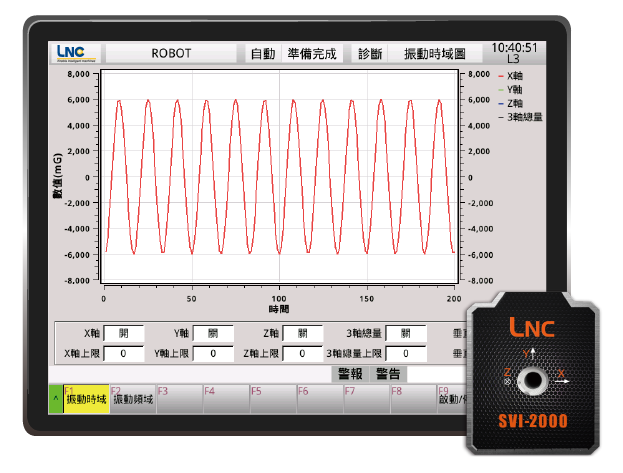

LNC TECHNOLOGY CO., LTD.

Product Description :

‧Low profile, high performance, easy installation, high applicability

‧High sensitivity, high precision

‧measurement:±16G, extremely low signal /noise ratio

‧XYZ three-axis vibration detection

‧Measuring frequency 3.32kHz(max.)

‧EtherCAT protocol

‧Water and oil proof, great anti-interference ability

‧Support time domain graph, frequency domain graph, abnormal vibration section marking of program function

‧Support smart function development: Broken tool detection, abnormal vibration detection, spindle protection, tool wear, adjustment assistance, equipment health inspection, etc.

BLUM PRODUCTION METROLOGY CO., LTD.

Product Description :

– THOUSANDS OF MEASURING VALUES OF ALL TOOL CUTTING EDGES PER SECOND

– UP TO 60% LESS MEASURING AND CHECKING TIME

– MEASUREMENT AND MONITORING OF ALL KINDS OF TOOLS, TOOL FORMS AND CUTTING MATERIALS

– COMPENSATION OF SPINDLE DRIFT AND TOOL CUTTING EDGE RUN-OUT ERRORS

LASER APPLICATION TECHNOLOGY CO., LTD.

Product Description :

◎ Tool Length Measurement

◎ Tool Radius Measurement

◎ Tool Breakage Detection

◎ Spindle Runout Analysis

◎ Three Axes Backlash Analysis

◎ Spindle Inclination Analysis

◎ Online Thermal Displacement Automatic Modeling and Compensation

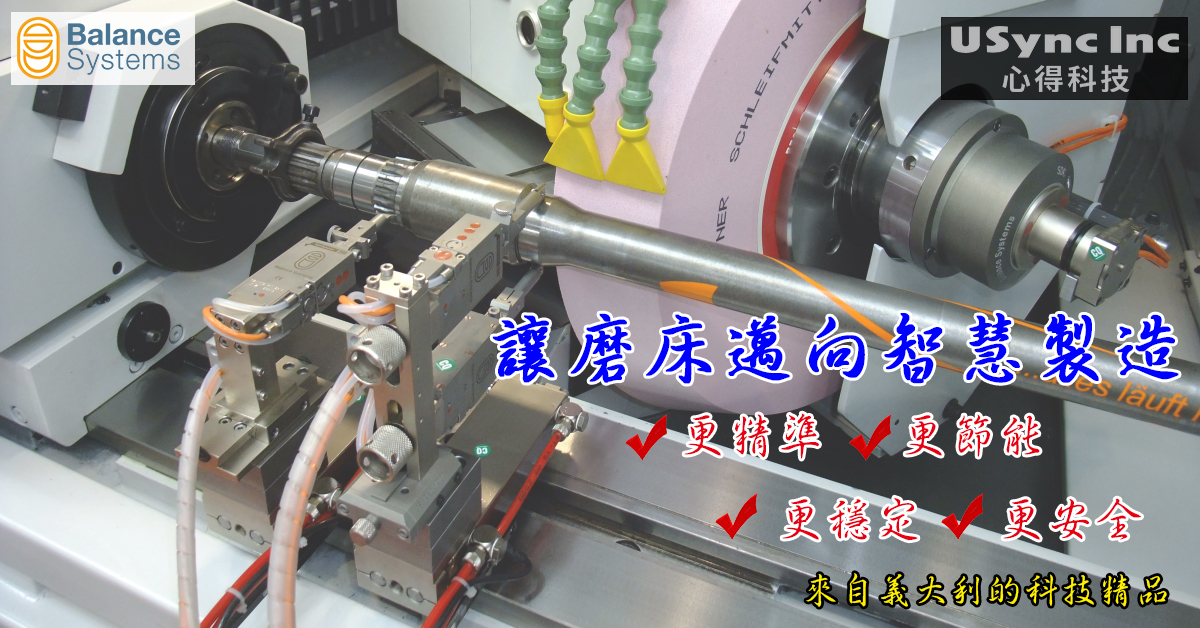

USYNC INC.

Product Description :

"VM25" is a high-performance application of a fully modular system designed for grinding machines, including automatic balancing on the 1 and 2 sides of the grinding wheel spindle, the use of audio detection to control the contact of the grinding wheel to the workpiece or sand, online Measurement and off-line measurement (absolute or relative) and other functions.

"B-Safe" can provide vibration and temperature information of the main shaft to detect and monitor the status analysis of the main shaft and machine. It is a new thinking product for intelligent monitoring. Its miniaturized volume design helps to install directly on the main shaft, ensuring that it can provide immediate monitoring of abnormal operating conditions, further predicting the timing of maintenance and failures, protecting your machine and reducing downtime.