Theme

Digital Transformation

Green Transformation

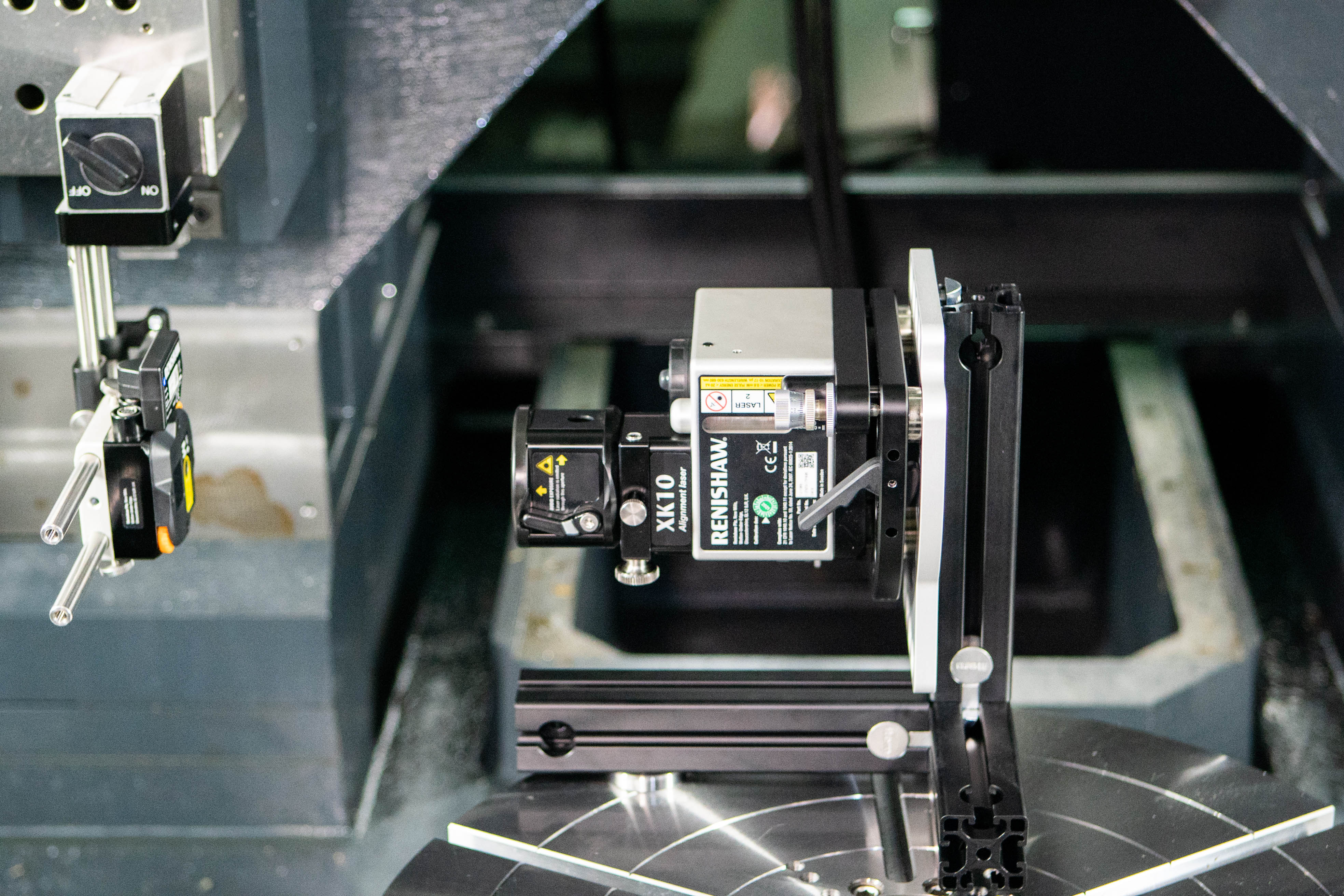

RENISHAW (TAIWAN) INC.

Product Description :

XK10 校準雷射系統是為了量測工具機的幾何和旋轉誤差而開發。與 XK10 工具機夾具套件搭配使用,能以比量錶、自動視準儀、量測治具等傳統方法更快、更簡單的方式進行量測。此系統可用於線性導軌,以確保導軌筆直、方正、平整、平行及水平,並可用於評估旋轉機器的主軸方向及同軸度。

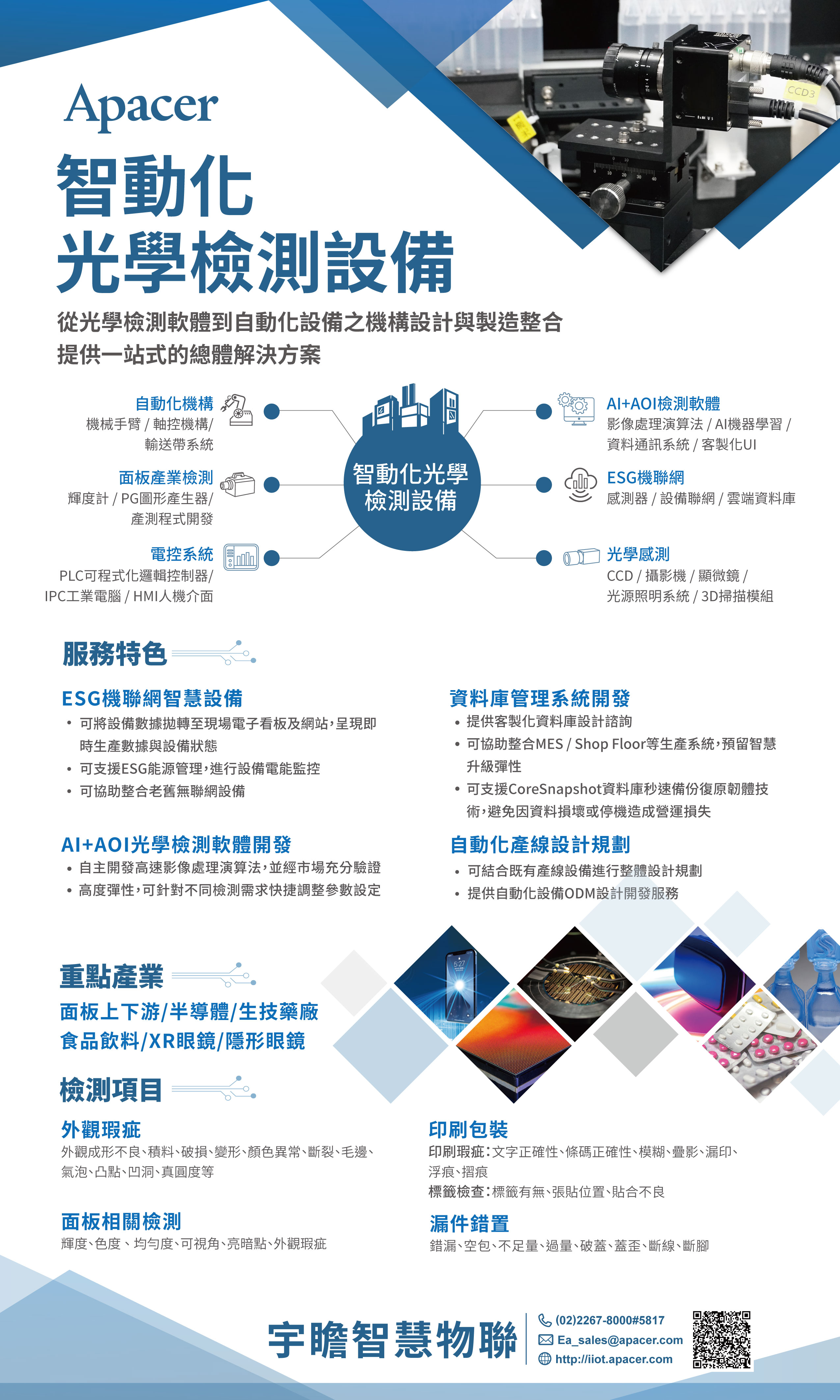

APACER TECHNOLOGY INC.

Product Description :

從光學檢測軟體到自動化設備之機構設計與製造整合

提供一站式的總體解決方案。

客製化規劃,專業設計開發AI+AOI光學檢測機台,可串連現有機台,設計全新自動化流程,提升瑕疵檢測的效率、降低人力成本。適用於面板業、生技藥廠、半導體、食品飲料等產業的各式瑕疵檢測應用。

瞭解更多:https://iiot.apacer.com/tw/optical-inspection/ai-aoi-automation/

更多實績案例,歡迎參考Apacer宇瞻智慧物聯官網:https://iiot.apacer.com/tw/case-studies/

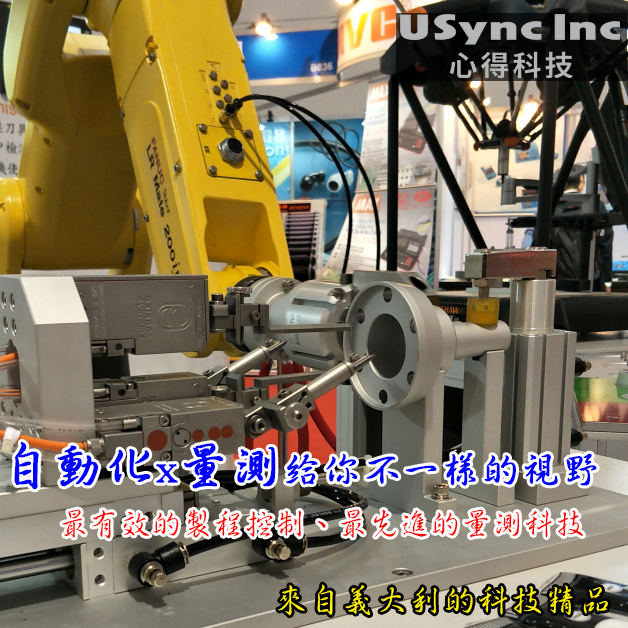

USYNC INC.

Product Description :

心得科技整合機械手臂、客製化料台、量測站與量測軟體,打造自動化機台,解決人力工時、工件品質保障、加工產能等製程問題,大幅提升加工機附加價值和競爭力。

量測站提高工件品質,並有效控制良率,不受外部環境與人員失誤影響,是自動化產線不可或缺的環節。

LASER APPLICATION TECHNOLOGY CO., LTD.

Product Description :

◎ Tool Length Measurement

◎ Tool Radius Measurement

◎ Tool Breakage Detection

◎ Spindle Runout Analysis *

◎ Two Axes Backlash Analysis *

◎ Ultrasonic Amplitude Measurement and Feedback

SOLIDWIZARD TECHNOLOGY

Product Description :

精度更高 視野更大,以小巧身材可以毫不費力地進行專業逆向工程和品質檢測。針對小型物件的3D掃描機能精準達到5微米精度,為工業零件、牙科和珠寶領域創造高精度全彩3D模型。也可以結合掃描與攝影測量數據,直接在您面前打造出更高水準的逼真效果。

KTR TAIWAN LTD.

Product Description :

ROTEX® torsional flexible couplings are characterized by small dimensions, low weight and low mass moments of inertia yet transmit high torques. Running quality and service life of the coupling are improved by accurate all-over machining. Their application is ideal for transmitting torque while damping torsional vibrations and absorbing shocks produced by the uneven operation of certain prime movers.

ROTEX® torsional flexible couplings are equipped with the new temperature resistant T-PUR® spider which is available in three different degrees of Shore hardness.

BLUM PRODUCTION METROLOGY CO., LTD.

Product Description :

– THOUSANDS OF MEASURING VALUES OF ALL TOOL CUTTING EDGES PER SECOND

– UP TO 60% LESS MEASURING AND CHECKING TIME

– MEASUREMENT AND MONITORING OF ALL KINDS OF TOOLS, TOOL FORMS AND CUTTING MATERIALS

– COMPENSATION OF SPINDLE DRIFT AND TOOL CUTTING EDGE RUN-OUT ERRORS

YINSH PRECISION INDUSTRIAL CO., LTD.

Product Description :

『軸向力感測器』,是由其研發設計中心暨精密螺帽檢測實驗室所設計開發測試,為目前市面上專屬為主軸用精密螺帽設計之預壓感測器,其功能正是用以測量精密螺帽在鎖緊時,施予扭力後會有多少軸向力施壓在被鎖物上,除此之外,還可自行檢查主軸在組裝時的品質是否穩定,進行預壓值數據之比對,目前產品提供三種規格,並配合實驗級別之上下墊圈,可測量M40至M170之螺帽軸向預壓,其可量測之最大預壓力為4000kgf,且已申請相關國內外專利

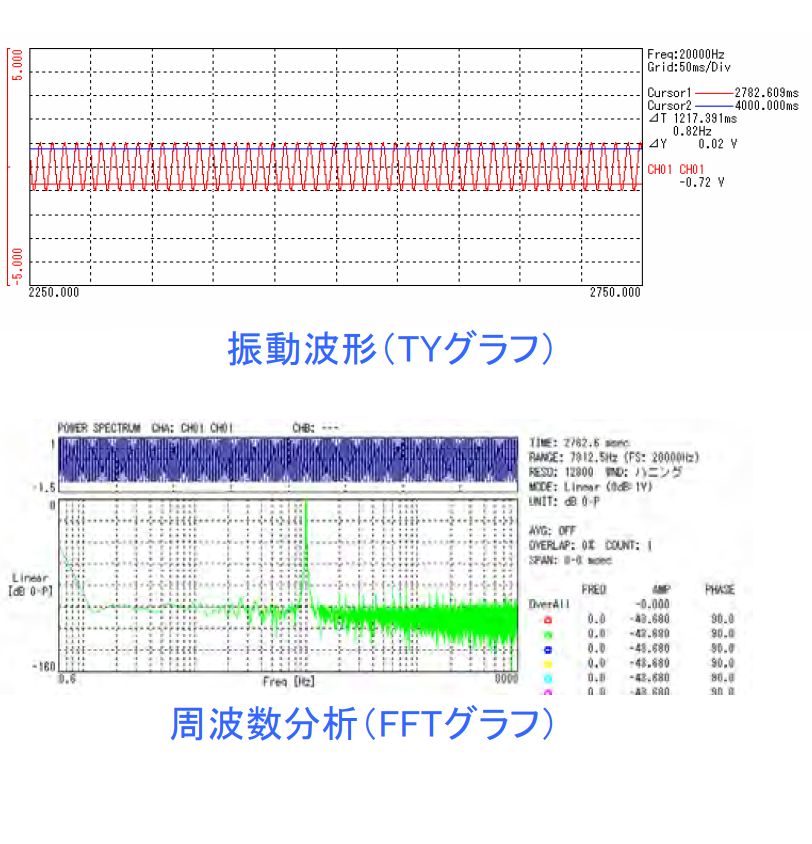

EQP SERIES CO., LTD

Product Description :

Connect various vibration meters for vibration analysis.

It is a waveform acquisition and analysis software capable of handling up to 32 channels.

It provides waveform (TY) graphs, FFT graphs, XY graphs.

Real-time or post-processing waveform analysis is possible.

You can add any filters or perform recalculations in post-processing.

It also allows for audio playback of waveform data.

Compatible with various types of vibration meters.

FARSIGHT PRECISION CO., LTD.

Product Description :

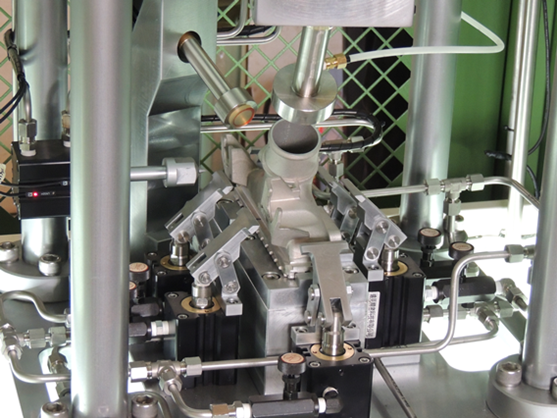

Finished leaking testing just only 1 minute !!!

Leaking Testing Machine (Pressure testing machine)

◎ Our company could according to products request of

condition of client, design and manufacturing dry type,

wet type or dry-wet 2 ways in one leaking testing

machine.

◎ 2 workpiece finished at the same time.

◎ The client can select the "COSMO", "FUKUDA" or other

leaking testing instrument, and install user-interface

system.

◎ Attach computer storage, calculation and network output

etc...

◎ The equipment could exchange the workpiece quickly.

◎ The equipment could exchange fixtures for other

workpiece.

◎ It can set the water tank in time.

◎ The client can option to mark on workpiece with laser or

punching.

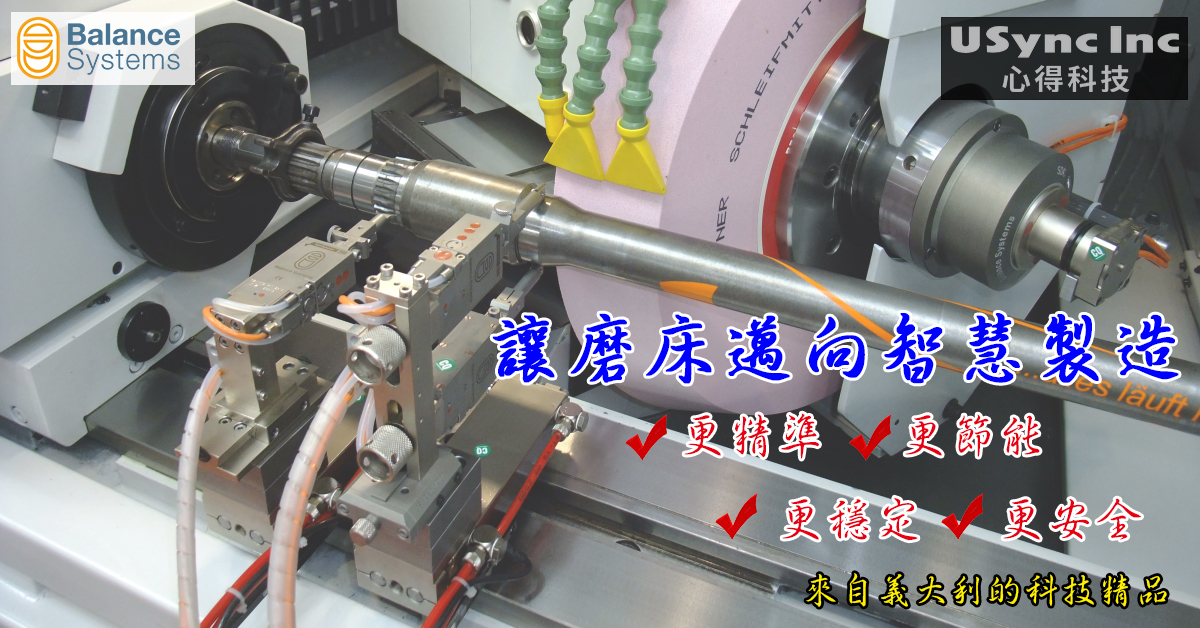

USYNC INC.

Product Description :

"VM25" is a high-performance application of a fully modular system designed for grinding machines, including automatic balancing on the 1 and 2 sides of the grinding wheel spindle, the use of audio detection to control the contact of the grinding wheel to the workpiece or sand, online Measurement and off-line measurement (absolute or relative) and other functions.

"B-Safe" can provide vibration and temperature information of the main shaft to detect and monitor the status analysis of the main shaft and machine. It is a new thinking product for intelligent monitoring. Its miniaturized volume design helps to install directly on the main shaft, ensuring that it can provide immediate monitoring of abnormal operating conditions, further predicting the timing of maintenance and failures, protecting your machine and reducing downtime.