Theme

Digital Transformation

Green Transformation

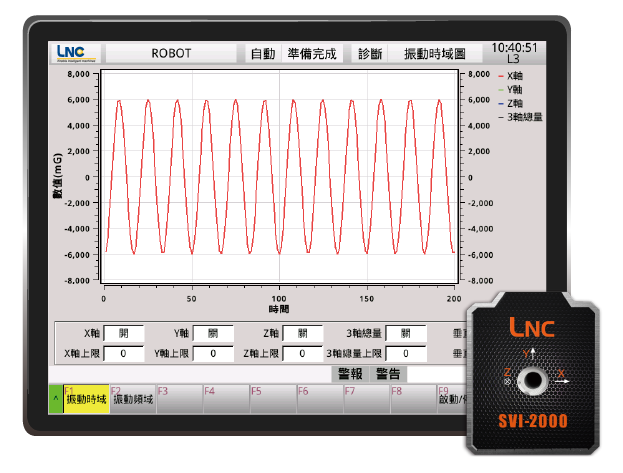

LNC TECHNOLOGY CO., LTD.

Product Description :

‧Low profile, high performance, easy installation, high applicability

‧High sensitivity, high precision

‧measurement:±16G, extremely low signal /noise ratio

‧XYZ three-axis vibration detection

‧Measuring frequency 3.32kHz(max.)

‧EtherCAT protocol

‧Water and oil proof, great anti-interference ability

‧Support time domain graph, frequency domain graph, abnormal vibration section marking of program function

‧Support smart function development: Broken tool detection, abnormal vibration detection, spindle protection, tool wear, adjustment assistance, equipment health inspection, etc.

RAISE PRECISION CO., LTD.

Product Description :

CAPTRON, pioneer of the first capacitive two-hand control system, ensure the highest safety category according to (Cat. 4) and PL e (DIN EN ISO 13849-1). The capacitive "safeCAP" two-hand control allows heavy machinery and systems in automated production plants, such as presses and punches, to be controlled safely and without pressure.

To start the machine the user simultaneously presses two capacitive buttons which are connected to a safety relay. Incorrect or inattentive control using just one hand or with another part of the body is detected by the system and the machine is not started.

CAPTRON supplies the safeCAP two-hand control with additional safety elements such as the Protector or the control desk for tabletop installation. These combinations enhance protection and are certified to DIN EN 574. The dynamically switching SENSORswitches detect interference factors such as dirt, dust or foreign bodies. The switches can be actuated using disposable or work gloves, however.

EQP SERIES CO., LTD

Product Description :

This system is versatile and can be used not only for general vibration monitoring but also for measurements in challenging environments and is compatible with intrinsic safety and explosion-proof requirements. The Vibrating Converter MODEL-2503 is a system that can accommodate various sensors and specifications.

A vibration monitoring system using the Intrinsic Safety Explosion-proof Detector MODEL-2450EX is composed of detectors, barriers (safety retainers), and MODEL-2503 installed in hazardous locations.

The output includes not only DC4-20mA but also two systems of vibrating waveform AC±2V. This allows not only observation on digital monitors but also connectivity to various PLCs, contributing to the IoT compatibility of facilities.

Can be used in conjunction with the high-sensitivity piezoelectric accelerometer MODEL2430.

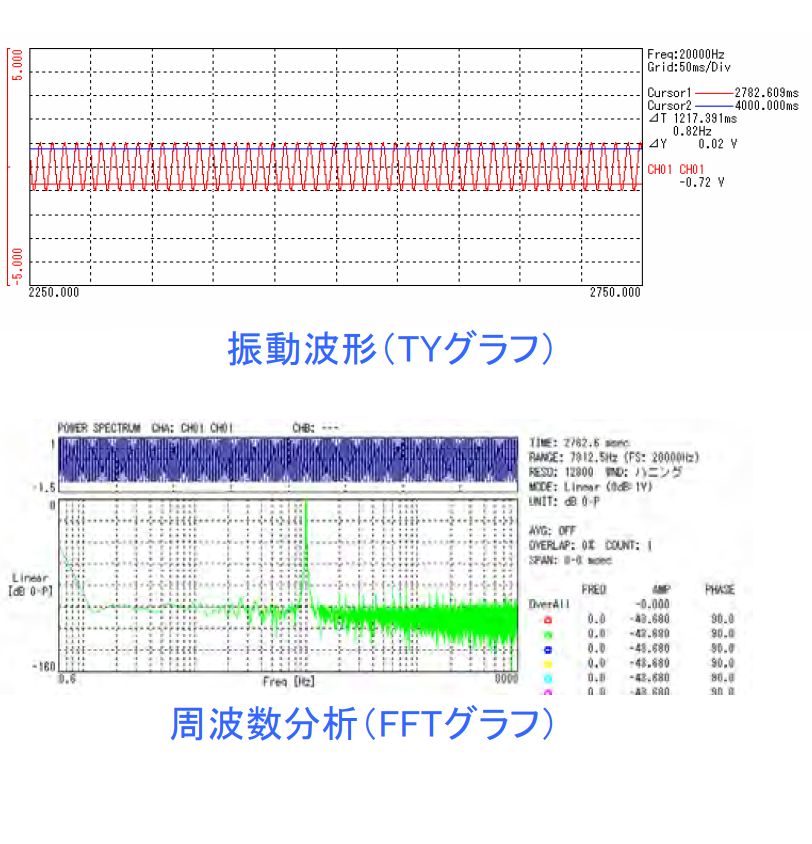

EQP SERIES CO., LTD

Product Description :

Connect various vibration meters for vibration analysis.

It is a waveform acquisition and analysis software capable of handling up to 32 channels.

It provides waveform (TY) graphs, FFT graphs, XY graphs.

Real-time or post-processing waveform analysis is possible.

You can add any filters or perform recalculations in post-processing.

It also allows for audio playback of waveform data.

Compatible with various types of vibration meters.

EQP SERIES CO., LTD

Product Description :

General-purpose, low-cost vibration sensor with an integrated sensor and amplifier, and an output current ranging from 4 to 20 mA. This low-cost and straightforward vibration monitoring sensor is ideal for controlling and monitoring rotating machinery. It offers three measurement modes: displacement measurement, velocity measurement, and acceleration measurement.

Due to the 4-20 mA DC output, it can be directly connected to recorders, displays, timing circuits, and other equipment. The integrated design of the sensor and amplifier eliminates the need for a separate vibration meter amplifier. It operates on a 2-wire system, comprising power and signal lines, with no polarity considerations during connection.

By connecting to a dedicated monitor or instrument relay, it can be used as a vibration meter or vibration measuring instrument. It is also compatible with Fuji Electric's MVM series.

※Can be used in conjunction with the Model-2590C display.

TES ELECTRICAL ELECTRONIC CORP.

Product Description :

FEATURES :

• 10 Display Easy - to - View LCD Screen.

• Connectors for 4 Current Sensing Clamps.

• 1P2W, 1P3W, 3P3W2M, 3P3W3M & 3P4W Power Measurement.

• True RMS Sensing.

• Power KW, KVAR, KVA, PF,θ,Hz, &

Energy KWh, KVARh & KVAh Measurement.

• Phase sequency indicator function.

• Backlight display function.

• Manual Data Memory and Read (50 sets).

• Data Logging

• USB Optical Interface with three phase voltage /

current Waveform display and Harmonic analysis.

• Easy - to - use Push - Button Operation.

• Light Weight, Portable Design.

EQP SERIES CO., LTD

Product Description :

Voltage Sensitivity: 10mV/(m/s²)±10%

Power Supply: DC15~36V

Constant Current: 0.5~10mA

Resonant Frequency: Approximately 40kHz

Frequency Response: 5~10kHz (±3dB)

Maximum Acceleration: 220m/s²

Shock Resistance: 49,000m/s²

Noise Level: Below 100μVRMS

Operating Temperature Range: -50~110℃

Detection Structure: Shear Type

Case Material: Titanium

Mass: Approximately 10g

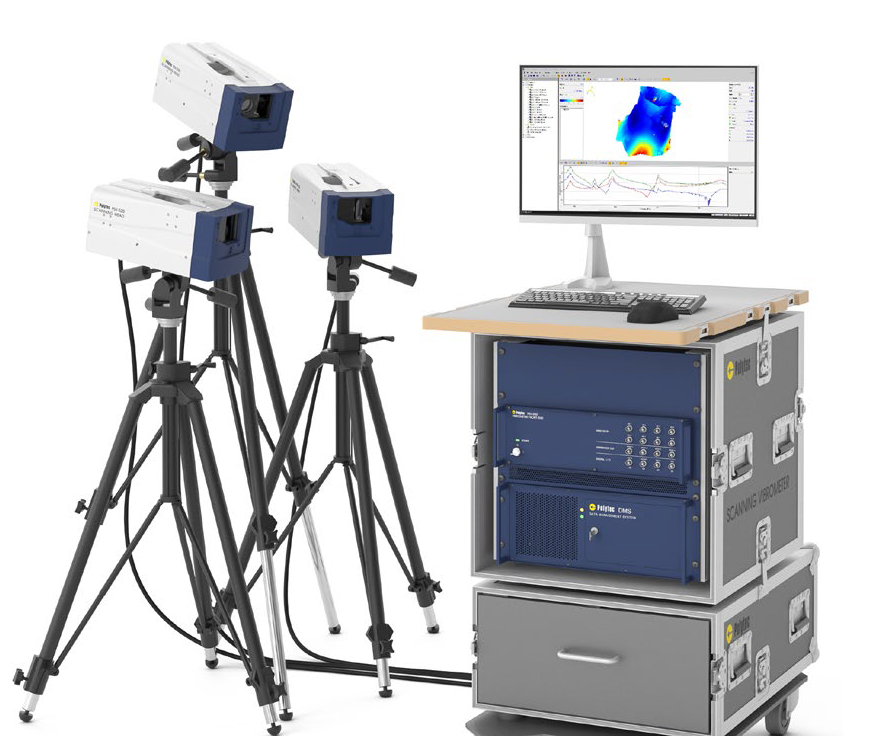

Taiwan Auto-Design Co.

Product Description :

Polytec 3D Scanning Vibrometers are state-of-the-art

for noise and vibration measurement in research and

development. Using three independent scanning

heads they deliver the full information on all vibrational

directions. The PSV-500-3D determines operational

deflection shapes and Eigenmodes for NVH, acoustics,

structural dynamics, ultrasonics, and FEM validation.

The high frequency version up to 25 MHz extends the

application range to non-destructive evaluation (NDE)

research. Every PSV-500-3D integrates perfectly into the CAE world providing interfaces to 3D geometries,

modal analysis and automation. The scanning heads

based on helium-neon laser allow measurements

even on tiny structures due to their especially small

laser spot.

PSV Scanning Vibrometers are available as

a compact laptop version or as a practical rack-type

workstation.

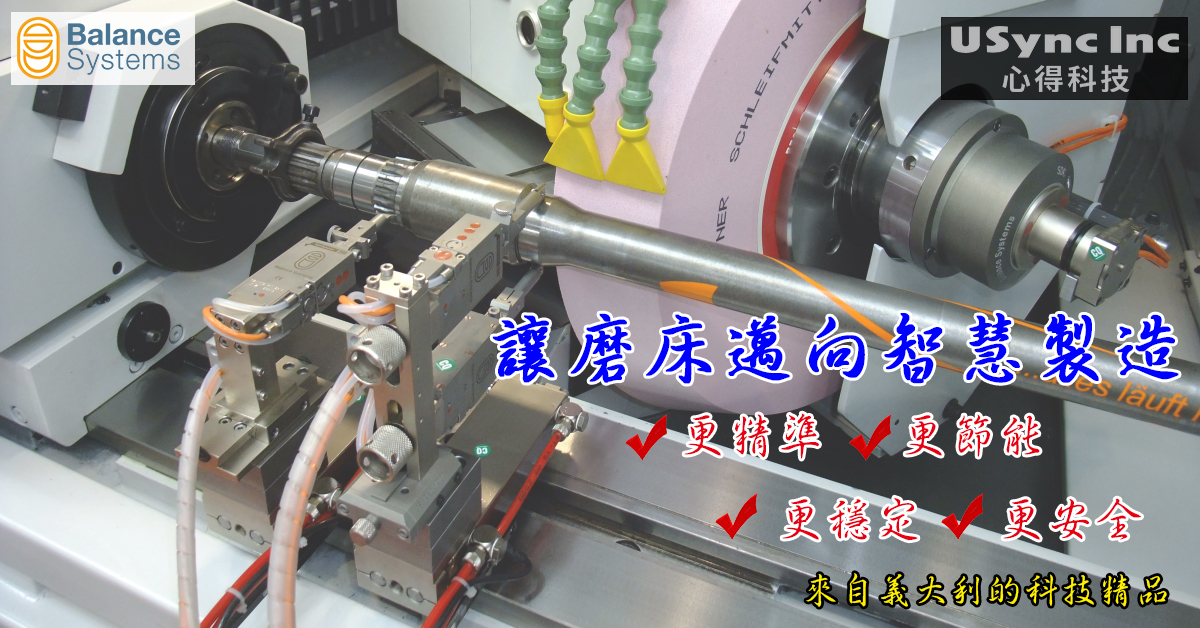

USYNC INC.

Product Description :

"VM25" is a high-performance application of a fully modular system designed for grinding machines, including automatic balancing on the 1 and 2 sides of the grinding wheel spindle, the use of audio detection to control the contact of the grinding wheel to the workpiece or sand, online Measurement and off-line measurement (absolute or relative) and other functions.

"B-Safe" can provide vibration and temperature information of the main shaft to detect and monitor the status analysis of the main shaft and machine. It is a new thinking product for intelligent monitoring. Its miniaturized volume design helps to install directly on the main shaft, ensuring that it can provide immediate monitoring of abnormal operating conditions, further predicting the timing of maintenance and failures, protecting your machine and reducing downtime.

KTR TAIWAN LTD.

Product Description :

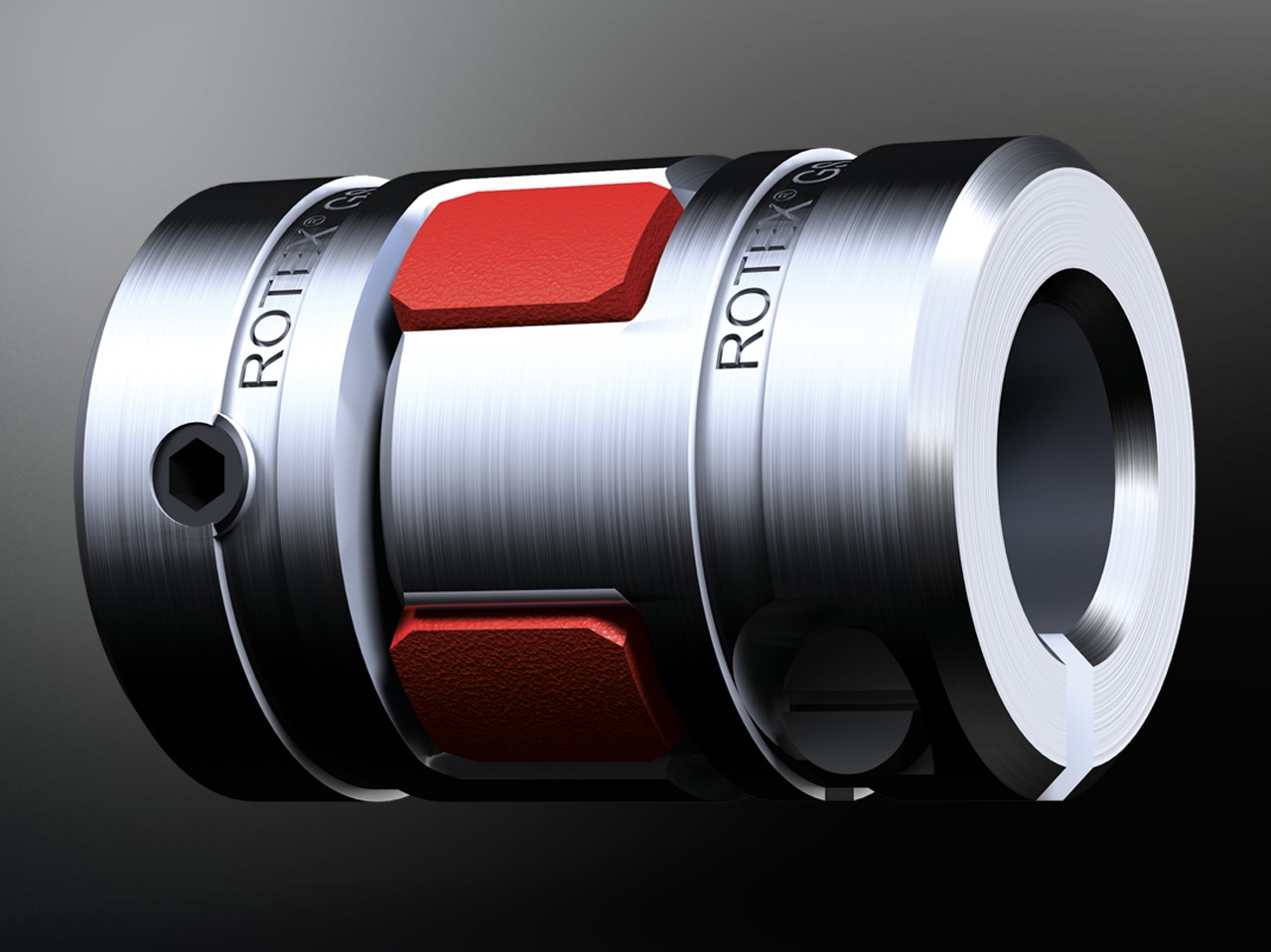

ROTEX® GS is a three-part coupling, backlash-free under pre-stress. The different hub designs and the different Shore hardnesses offer the optimal coupling for each application in automation engineering. In spite of its vibration-damping characteristics it is torsionally stiff so that it is not necessary to make any concessions to accuracy even with highly dynamic servo drives. The ROTEX GS works with the modular system; a high variety of different hub designs is available which can be combined within one coupling size.

G-TECH INSTRUMENTS INC.

Product Description :

The performance of the spindle is an important key to processing quality. When you understand the performance of the spindle, you can predict and control the quality of the processed parts. The shape accuracy, roundness, and surface roughness of the workpieces are all related to the performance of the spindle. Only when the spindle is real measuring the accuracy of the spindle at the processing speed of the machine has meaning to the control of the quality of the processed parts, so measuring and understanding the performance of the machine tool, finding the best working speed, determining the warm-up time, even confirm the accuracy of the spindle after the collision.

LION provided this SEA analysis system as early as 1993 to help spindle manufacturers, machine tool factories and processing plants to reduce workpiece defect rate and improve product quality.

★The SEA system complies with the following international standards:

✓ ANSI / ASME B5.54-2005: "Methods for Performance Evaluation of CNC Machining Centers"

✓ ISO230: Test Code for Machine Tools, 3: "Determination of Thermal Effects" 7: "Geometric Accuracy of Axes of Rotation"

✓ ANSI / ASME B5.57-1998: "Methods for Performance Evaluation of CNC Turning Centers"

✓ ANSI / ASME B89.3.4: "Axes of Rotation, Methods for Specifying and Testing"