Theme

Digital Transformation

Green Transformation

EQP SERIES CO., LTD

Product Description :

General-purpose, low-cost vibration sensor with an integrated sensor and amplifier, and an output current ranging from 4 to 20 mA. This low-cost and straightforward vibration monitoring sensor is ideal for controlling and monitoring rotating machinery. It offers three measurement modes: displacement measurement, velocity measurement, and acceleration measurement.

Due to the 4-20 mA DC output, it can be directly connected to recorders, displays, timing circuits, and other equipment. The integrated design of the sensor and amplifier eliminates the need for a separate vibration meter amplifier. It operates on a 2-wire system, comprising power and signal lines, with no polarity considerations during connection.

By connecting to a dedicated monitor or instrument relay, it can be used as a vibration meter or vibration measuring instrument. It is also compatible with Fuji Electric's MVM series.

※Can be used in conjunction with the Model-2590C display.

BLUM PRODUCTION METROLOGY CO., LTD.

Product Description :

• Measuring speed up to 3 m/min

• Precise non-lobing touch characteristics

• No-wear, optoelectronic measuring mechanism

• Easy pairing procedure between probe and receiver

• Use of up to 6 measuring systems with one receiver

• Extended battery life

• Precise measurement even with coolant

EQP SERIES CO., LTD

Product Description :

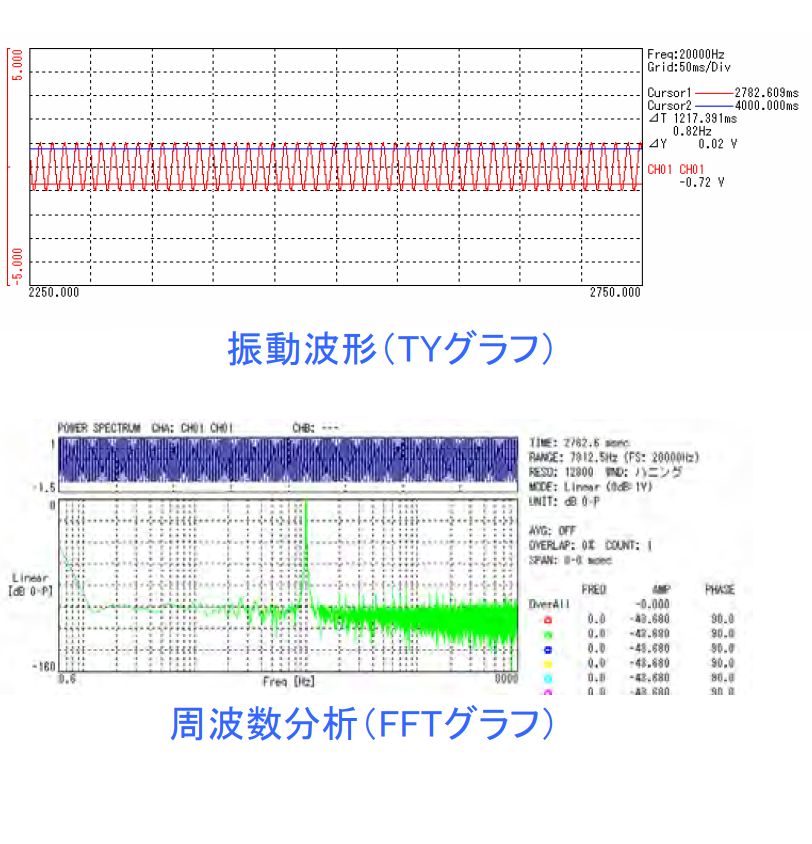

Connect various vibration meters for vibration analysis.

It is a waveform acquisition and analysis software capable of handling up to 32 channels.

It provides waveform (TY) graphs, FFT graphs, XY graphs.

Real-time or post-processing waveform analysis is possible.

You can add any filters or perform recalculations in post-processing.

It also allows for audio playback of waveform data.

Compatible with various types of vibration meters.

BLUM PRODUCTION METROLOGY CO., LTD.

Product Description :

• Measuring speed up to 3 m/min

• Precise, non-lobing touch characteristics

• No-wear, optoelectronic measuring mechanism

• Use of two measuring systems with one IR receiver

• Extended battery life

• Precise measurement even with coolant

• Proven and robust design

KTR TAIWAN LTD.

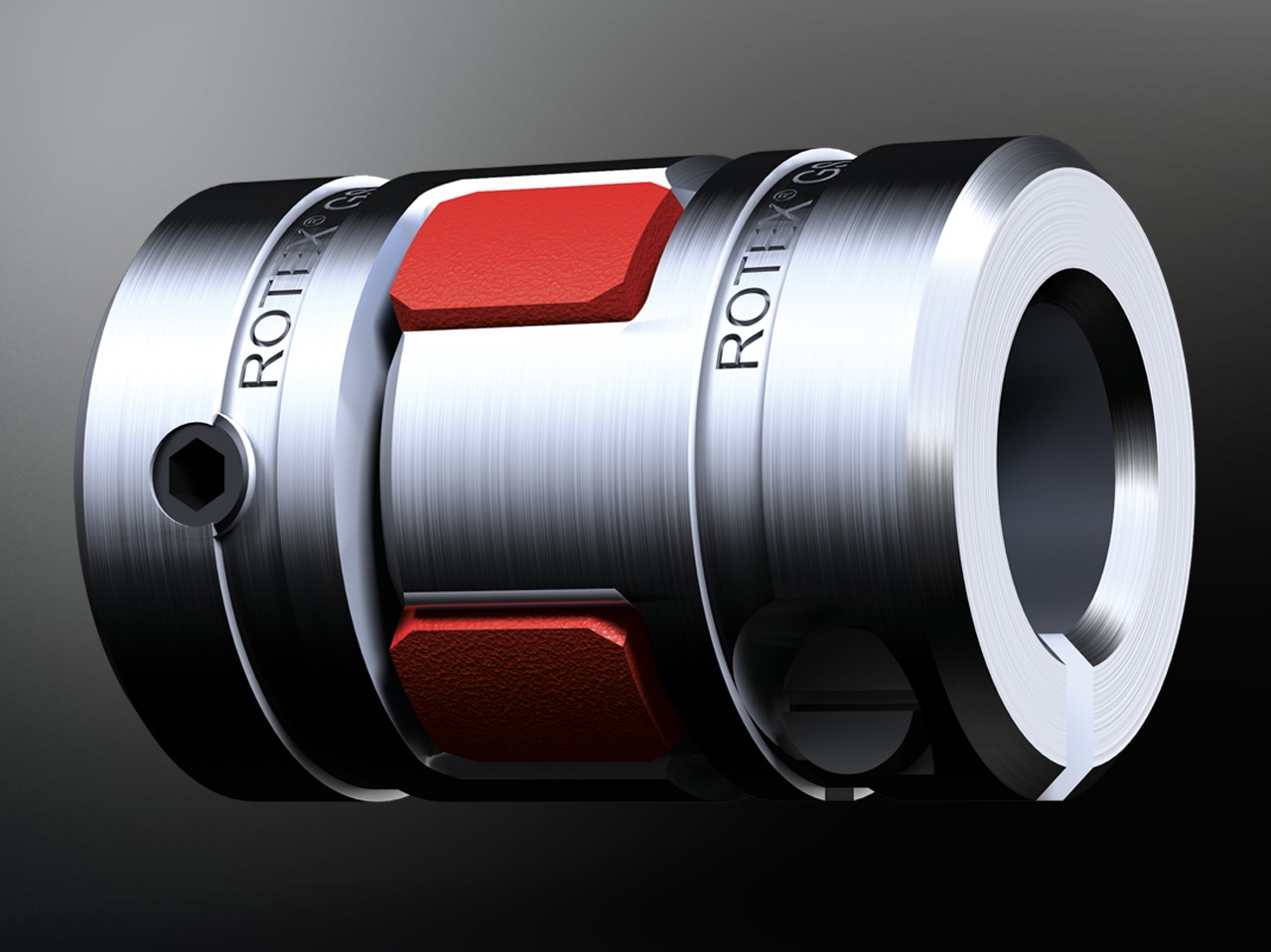

Product Description :

ROTEX® GS is a three-part coupling, backlash-free under pre-stress. The different hub designs and the different Shore hardnesses offer the optimal coupling for each application in automation engineering. In spite of its vibration-damping characteristics it is torsionally stiff so that it is not necessary to make any concessions to accuracy even with highly dynamic servo drives. The ROTEX GS works with the modular system; a high variety of different hub designs is available which can be combined within one coupling size.

BLUM PRODUCTION METROLOGY CO., LTD.

Product Description :

– THOUSANDS OF MEASURING VALUES OF ALL TOOL CUTTING EDGES PER SECOND

– UP TO 60% LESS MEASURING AND CHECKING TIME

– MEASUREMENT AND MONITORING OF ALL KINDS OF TOOLS, TOOL FORMS AND CUTTING MATERIALS

– COMPENSATION OF SPINDLE DRIFT AND TOOL CUTTING EDGE RUN-OUT ERRORS

RAISE PRECISION CO., LTD.

Product Description :

The compact, high-resolution MiniCODERs have proven their value for speed and position acquisition in highly dynamic applications. They use their full potential when installation situations with little space require a particularly compact, robust and reliable measuring system. The magnetic measuring systems consist of a ferromagnetic target wheel and a scanning unit. Without dedicated bearings, they are completely wear-free and maintenance-free. The optimised circuit and screening technique, and fully encapsulated electronics ensure reliable operation even in harsh environments.

EQP SERIES CO., LTD

Product Description :

This system is versatile and can be used not only for general vibration monitoring but also for measurements in challenging environments and is compatible with intrinsic safety and explosion-proof requirements. The Vibrating Converter MODEL-2503 is a system that can accommodate various sensors and specifications.

A vibration monitoring system using the Intrinsic Safety Explosion-proof Detector MODEL-2450EX is composed of detectors, barriers (safety retainers), and MODEL-2503 installed in hazardous locations.

The output includes not only DC4-20mA but also two systems of vibrating waveform AC±2V. This allows not only observation on digital monitors but also connectivity to various PLCs, contributing to the IoT compatibility of facilities.

Can be used in conjunction with the high-sensitivity piezoelectric accelerometer MODEL2430.

TES ELECTRICAL ELECTRONIC CORP.

Product Description :

■ Measures acceleration, Velocity and displacement

■ Maximum/Minimum record function

■ Earphone output for detecting noise in machine components

■ Manual memory stores up to 99 data

■ RMS, EQ PEAK and EQ P-P measurement

■ Wide range of vibration measurement by using different sensitivity of accelerometers

■ Excellent accelerometer for harsh environments