Theme

Digital Transformation

Green Transformation

HC FENG CO., LTD.

Product Description :

FOODIE (Chip/Sludge Removal Machine) works for :

Filtration/Removal of excess components

Chip/Sludge Removal

Fine Chip Removal

No downtime

No consumables

Backwater automatically & simultaneously

Air pressure drive w/o a plug

Vertically fast filter drying up to 90% efficiency

Precision filters effective up 20% for super filtration micro-fines

Easy to move

Filter accuracy can be adjusted

Extend cutting fluid life

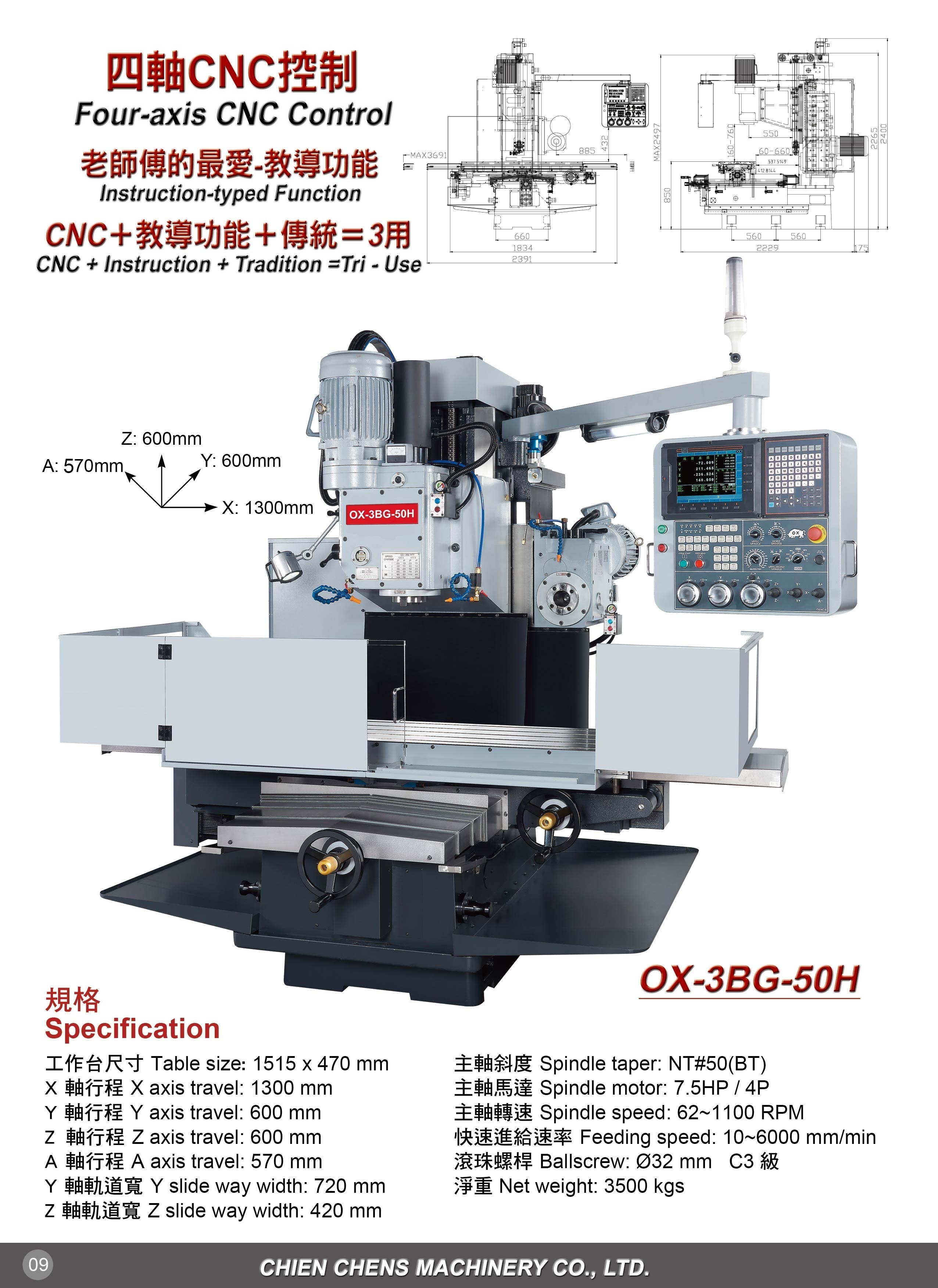

CHIEN CHENS MACHINERY CO., LTD.

Product Description :

Specification

Table size: 1515 x 470 mm

Longitudinal travel: 1300 mm

Cross travel: 600 mm

Y slide way width: 720 mm

Z Slide high: MAX 760 mm

Z Slide way width: 420 mm

Spindle taper: NT#50(BT)

Spindle motor: 7.5HP / 2P

Spindle speed: 62~1100 RPM

Feeding speed: 10~6000 mm/min

Ballscrew: Ø32 mm C5

Net weight: 3200 kgs

HC FENG CO., LTD.

Product Description :

4 in 1 Coolant Purification System

1. Filtering floating debris and dirty particles

2. Oil/Water Separation, removes tramp oil down to 5% water content

3. Ozone Disinfection, eliminates bacteria and cleaned fluid backflow

4. Automatic control panel and pH detect device

REN AN INFORMATION TECHNOLOGY CO., LTD.

Product Description :

Just like the real CNC machine, equipped with exactly same overall appearance, actual handwheel and real machine operation panel as numerical control machine.

Solving the difficulties of real machine: precise, complicated and very expensive.

With CNC Simulator, everyone can learn CNC machine operation and accumulate hands-on operation skills.

CNC training machine is equipped with exactly same overall appearance, actual handwheel and real machine

operation panel as numerical control machine. Its purpose is to train students for accumulating CNC machine operation skills (program transmission, programming, tool selection, tool compensation and alarm clear )

Overall design is more attractive, and it emphasizes on interaction to make students less mistakes happened.

Not only decreasing learning cost but also letting students work and learn in the safe environment.

CHIEN CHENS MACHINERY CO., LTD.

Product Description :

Specification

Table size: 1850 x 650 mm

Longitudinal travel: 1500 mm

Cross travel: 800 mm

Y slide way width: 1000 mm

Z Slide high: MAX 800 mm

Z Slide way width: 500 mm

Spindle taper: NT#50(BT)

Spindle motor: 7.5HP / 4P

Spindle speed: 40~3000 RPM

Feeding speed: 10~6000 mm/min

Ballscrew: Ø40 mm P=8 C3

Net weight: 5500 kgs

REN AN INFORMATION TECHNOLOGY CO., LTD.

Product Description :

RenAn's operation simulation workstation is a physical simulation with 3D graphic, showing the cutting and machining process.

[Save consumable cost]: There is no need to worry about the expenditure of consumables, and it will not be affected by pollutants such as waste materials and oil and gas.

[Safety]: Advanced 3D simulation and CNC virtual machine make high risk CNC operation without any danger.

[Smart learning]: Like training the pilot using flight simulators, we use CNC simulator to train the students or operators to be the machinist. Its industrial panel remains the same functionality as real machine that students can practice constantly to accumulate hands-on operation skills.

The controller series of simulator: Fanuc, Siemens, Heidenhain and Mitsubishi.

Turning, Milling, TurnMill, 4 axis, 5 axis.

HEIDENHAIN CO., LTD. (TAIWAN)

Product Description :

Angle encoders for rotary and tilting axes are indispensable for machine tools on which high positioning accuracy and a high machining rate are essential. Because angle encoder measure angular motion of the axis directly and immediately. Mechanical transfer elements therefore have no influence on position measurement, both kinematics errors and the influences of forces are measured by the angle encoder and considered in the position control loop. This can eliminate a number of potential error sources: Gear errors, reversal error, errors due to deformation of the drive mechanics by machining forces.

CHIEN CHENS MACHINERY CO., LTD.

Product Description :

Specification

Table size: 2600 x 650 mm

Longitudinal travel: 2400 mm

Cross travel: 800 mm

Y slide way width: 1980 mm

Z Slide high: MAX 800 mm

Z Slide way width: 500 mm

Spindle taper: NT#50(BT)

Spindle motor: 7.5HP / 4P

Spindle speed: 70~1200 RPM

Feeding speed: 10~6000 mm/min

Ballscrew: Ø40 mm P=8 C3

Net weight: 6800 kgs

FALCON MACHINE TOOLS CO., LTD.

Product Description :

Easy Setup, Flexible and Sealed for Grinding

The FVGC Series of vertical grinding machines is another prime example of Chevalier's position as the global leader in grinding technology. The series seamlessly increases efficiency and productivity for such industries as semiconductor, punch and aerospace, as well as other sectors for which these machines can be equipped. Workpieces in these fields primarily are a composite, single crystal silicon or brittle, along with other materials that present process challenges.

HEIDENHAIN CO., LTD. (TAIWAN)

Product Description :

Collision protection is a major topic at HEIDENHAIN. The touch probes feature a large deflection path and offer additional safety with rated breaking points in the stylus or the connecting pin to the probe contact.

The TS 460 and TT 460 touch probes feature intelligent battery management in order to minimize current consumption. The touch probe switches in steps to the stand by condition: The longer a touch probe has been switched off, the less current it consumes. Activating a touch probe from a low standby level takes only a split second longer. This ensures high, application oriented availability.

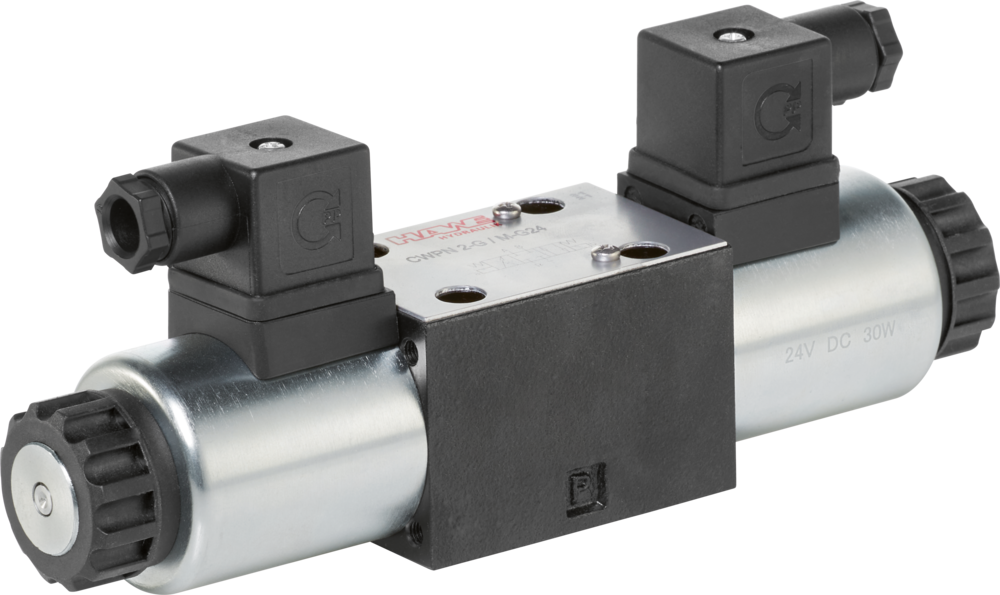

HAWE Hydraulik Singapore Pte. Ltd. Taiwan Branch

Product Description :

Directional spool valves are a type of directional valve. They control the direction of

movement and the velocity of single and double-acting hydraulic consumers.

The directional spool valve type CWPN is a 4/3- or 4/2-way directional valve with standard connection pattern NG 6 (CETOP 03). It is directly actuated and a binary

valve.

The directional spool valve type CWPN can be flexibly combined with the common HAWE valve banks and compact hydraulic power packs. It can also be mounted on customer-specific manifolds or sub-plates.

Features and benefits

■ Universally usable thanks to standard connection pattern NG 6 (CETOP 3) according to ISO 4401-03 or DIN 24 340-A6

■ Modular system with various circuit symbols and actuation variants

■ Optionally also available with additional valves in port P

Intended applications

■ Machine tools

■ Wind turbines

■ Solar power plants

■ Industrial hydraulics