Theme

Digital Transformation

Green Transformation

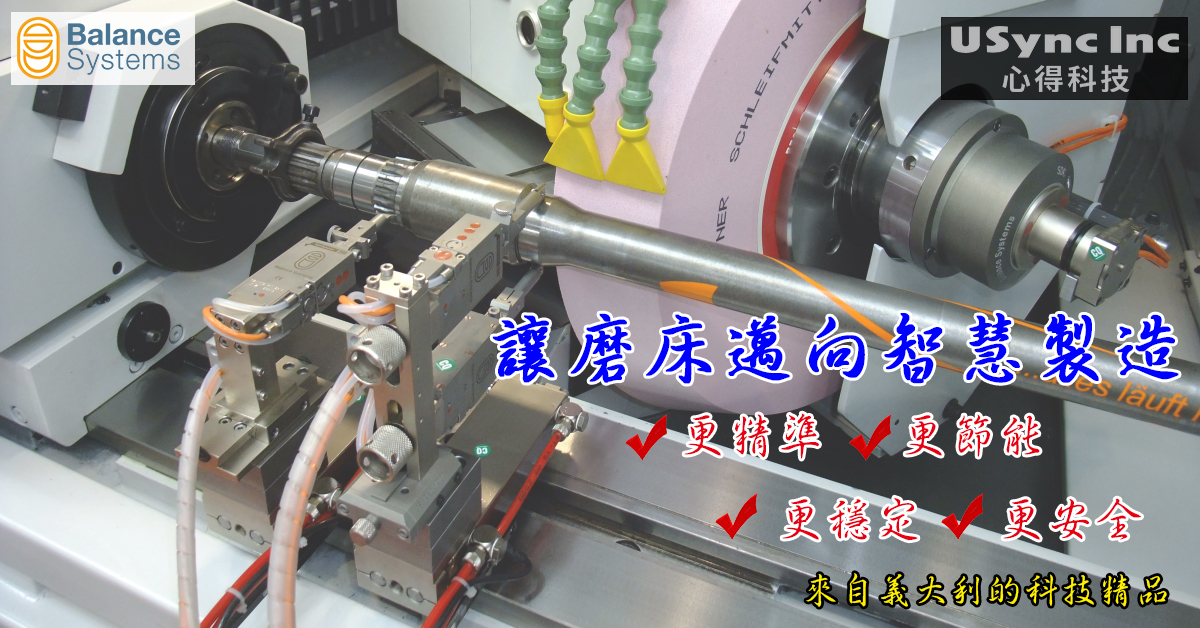

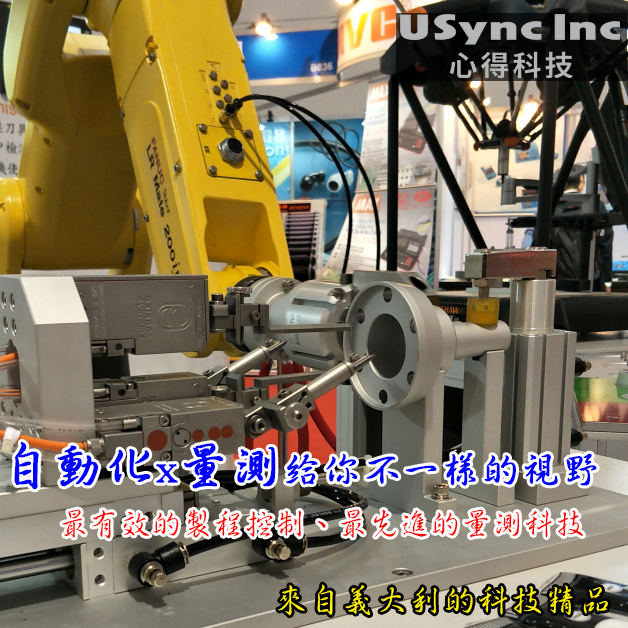

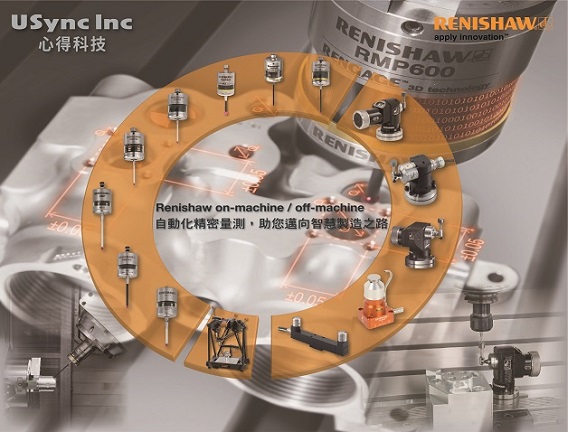

USYNC INC.

Product Description :

"VM25" is a high-performance application of a fully modular system designed for grinding machines, including automatic balancing on the 1 and 2 sides of the grinding wheel spindle, the use of audio detection to control the contact of the grinding wheel to the workpiece or sand, online Measurement and off-line measurement (absolute or relative) and other functions.

"B-Safe" can provide vibration and temperature information of the main shaft to detect and monitor the status analysis of the main shaft and machine. It is a new thinking product for intelligent monitoring. Its miniaturized volume design helps to install directly on the main shaft, ensuring that it can provide immediate monitoring of abnormal operating conditions, further predicting the timing of maintenance and failures, protecting your machine and reducing downtime.

EQP SERIES CO., LTD

Product Description :

Voltage Sensitivity: 10mV/(m/s²)±10%

Power Supply: DC15~36V

Constant Current: 0.5~10mA

Resonant Frequency: Approximately 40kHz

Frequency Response: 5~10kHz (±3dB)

Maximum Acceleration: 220m/s²

Shock Resistance: 49,000m/s²

Noise Level: Below 100μVRMS

Operating Temperature Range: -50~110℃

Detection Structure: Shear Type

Case Material: Titanium

Mass: Approximately 10g

EQP SERIES CO., LTD

Product Description :

This system is versatile and can be used not only for general vibration monitoring but also for measurements in challenging environments and is compatible with intrinsic safety and explosion-proof requirements. The Vibrating Converter MODEL-2503 is a system that can accommodate various sensors and specifications.

A vibration monitoring system using the Intrinsic Safety Explosion-proof Detector MODEL-2450EX is composed of detectors, barriers (safety retainers), and MODEL-2503 installed in hazardous locations.

The output includes not only DC4-20mA but also two systems of vibrating waveform AC±2V. This allows not only observation on digital monitors but also connectivity to various PLCs, contributing to the IoT compatibility of facilities.

Can be used in conjunction with the high-sensitivity piezoelectric accelerometer MODEL2430.

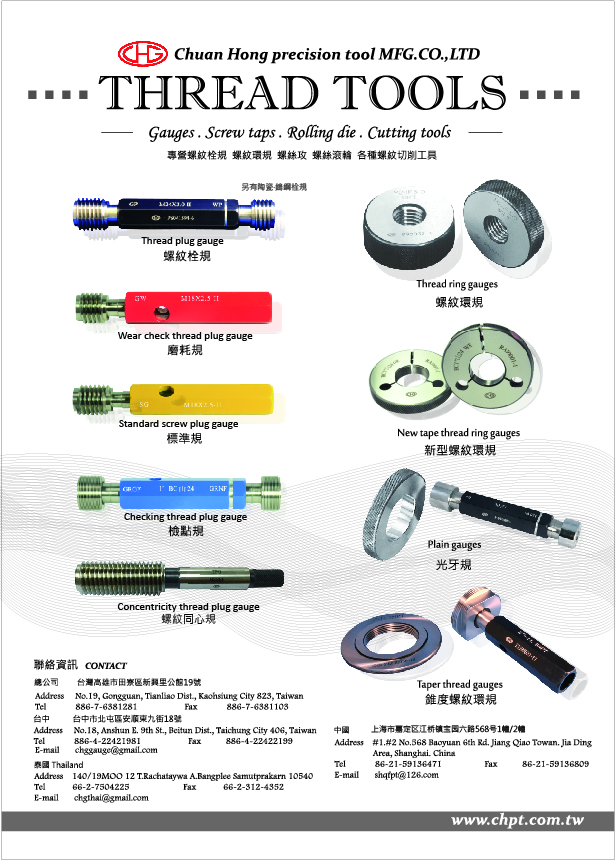

CHUAN HONG PRECISION TOOL MFG. CO., LTD.

Product Description :

<<栓規‧螺紋栓規>>

"栓規":專門檢查產品是否符合標準之量規。

"螺紋栓規":專門量測產品(母螺紋)是否符合廠內、國家或國際標準。

<<錐度栓規‧錐度螺紋栓規>>

"錐度栓規":專門檢查錐度產品(管用)是否符合標準之量規。

"錐度螺紋栓規":專門量測錐度產品(母螺紋)是否符合廠內、國家或國際標準。

<<環規‧螺紋環規>>

"環規":專門檢查產品是否符合標準之量規。

"螺紋環規":專門量測產品(公螺紋)是否符合廠內、國家或國際標準。

<<錐度栓規‧錐度螺紋栓規>>

"錐度栓規":專門檢查錐度產品(管用)是否符合標準之量規。

"錐度螺紋栓規":專門量測錐度產品(母螺紋)是否符合廠內、國家或國際標準。