Theme

Digital Transformation

Green Transformation

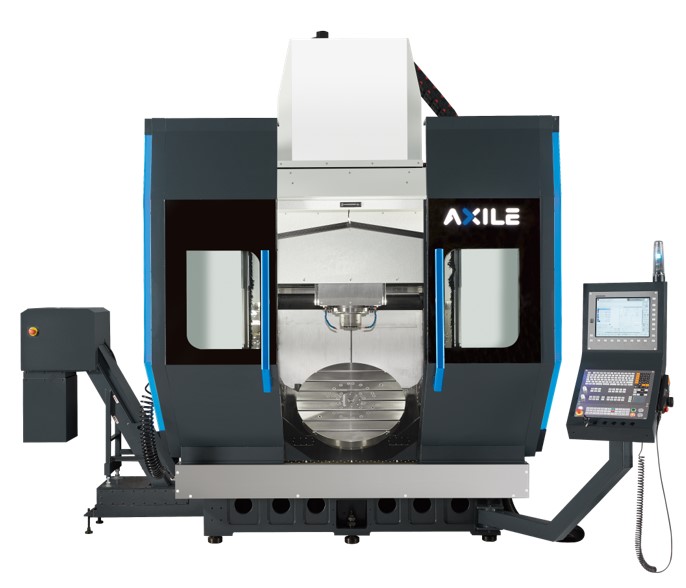

BUFFALO MACHINERY CO., LTD.

Product Description :

The AXILE G8’s powerful gantry design perfectly balances rigidity and precision, ideal for the machining of complex workpieces.

With a maximum loading capacity up to 1,300 kg on a swiveling, rotary table, complemented by high-performance built-in spindles, the G8's agility enables production of a wide range of large parts and tools.

The G8 MT option offers both milling and turning in one machine, greatly increasing operational flexibility. By reducing set-up times and potential clamping errors, the G8 MT can efficiently machine a wider variety of parts, including cylindrical components.

CHIEN CHENS MACHINERY CO., LTD.

Product Description :

Specification

Table size: 2600 x 650 mm

Longitudinal travel: 2400 mm

Cross travel: 800 mm

Y slide way width: 1980 mm

Z Slide high: MAX 800 mm

Z Slide way width: 500 mm

Spindle taper: NT#50(BT)

Spindle motor: 7.5HP / 4P

Spindle speed: 70~1200 RPM

Feeding speed: 10~6000 mm/min

Ballscrew: Ø40 mm P=8 C3

Net weight: 6800 kgs

YEONG CHIN MACHINERY INDUSTRIES CO., LTD.

Product Description :

NFX400A is designed especially for small, complex high-quality parts mainly for aerospace, automotive, medical, job shop and die & mold applications

■ Extra wide column and base design to ensure best support and cutting rigidity.

■ Increased tool life by cutting with belly and edge of the tool

■ Reduce fixture error and improve workpiece loading and uploading time

■ Greatly reduced non-cutting or setup waiting time

■ Saves manufacturing cost with reduced fixture and electrode costs.

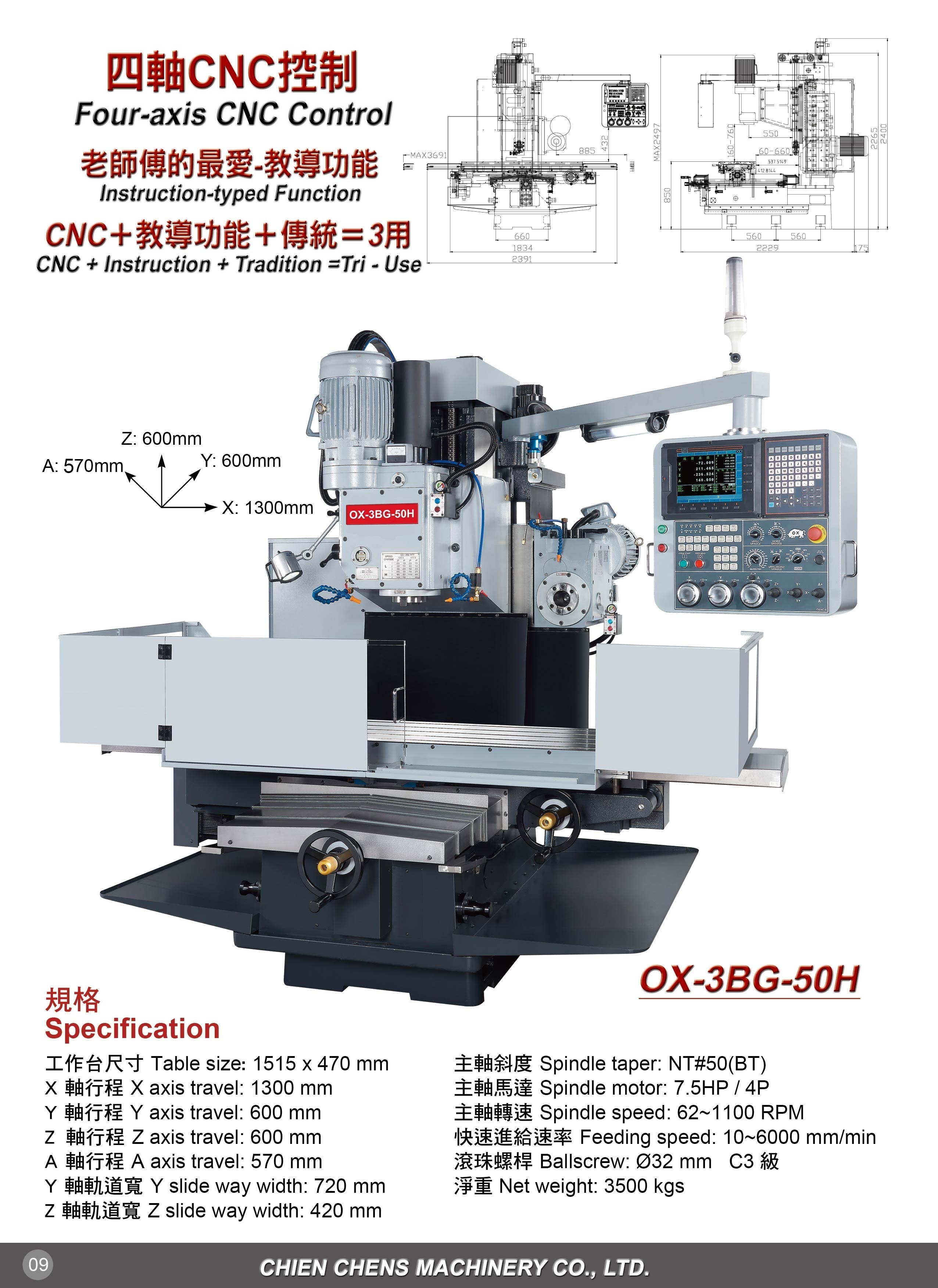

CHIEN CHENS MACHINERY CO., LTD.

Product Description :

Specification

Table size: 1515 x 470 mm

Longitudinal travel: 1300 mm

Cross travel: 600 mm

Y slide way width: 720 mm

Z Slide high: MAX 760 mm

Z Slide way width: 420 mm

Spindle taper: NT#50(BT)

Spindle motor: 7.5HP / 2P

Spindle speed: 62~1100 RPM

Feeding speed: 10~6000 mm/min

Ballscrew: Ø32 mm C5

Net weight: 3200 kgs

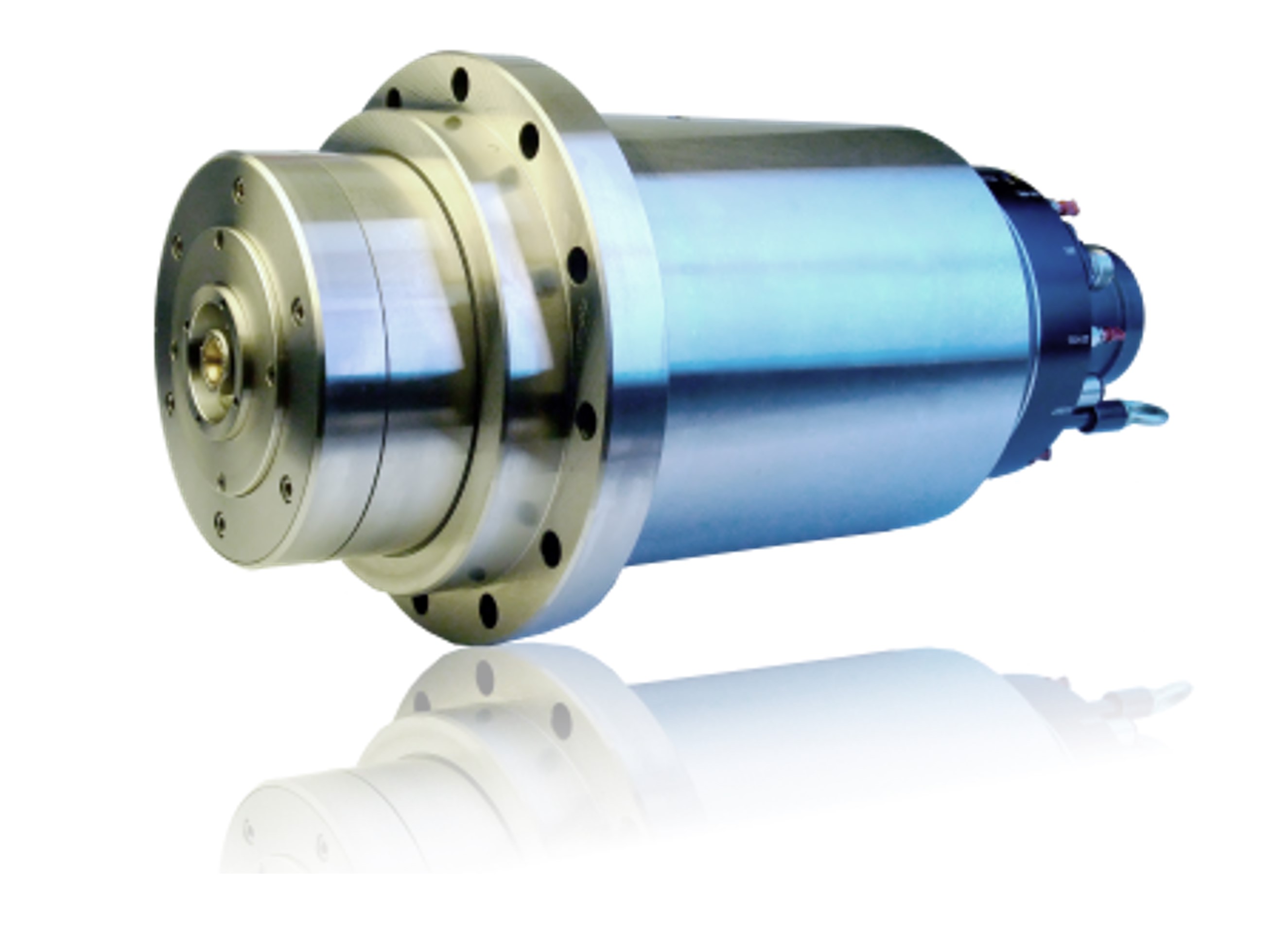

HEIDENHAIN CO., LTD. (TAIWAN)

Product Description :

In addition to milling operations, the TNC 640 also combines operations from milling, turning, and grinding processes. This sets the TNC 640 apart as a high-end control within its field of application. It is particularly well suited to HSC and 5-axis simultaneous machining, including on fully automated machining centers. The TNC 640 stands for perfect surface quality, exceptional accuracy, and very short machining times combined with shop-friendly operation and programming. On a milling/ turning machine with TNC 640, you machine the complete work piece on one machine in whatever sequence is needed. You can switch back and forth regardless of the machine and its axis configuration. The TNC 640 makes all necessary adjustments, e.g. switching to diameter display and setting the datum in the rotary table center. Batch Process Manager allows you to optimally plan and execute production jobs with great ease. With Batch Process Manager you can flexibly define the sequence of your jobs and, prior to machining, check to ensure that all of the required tools are available and that the NC program will run without errors.

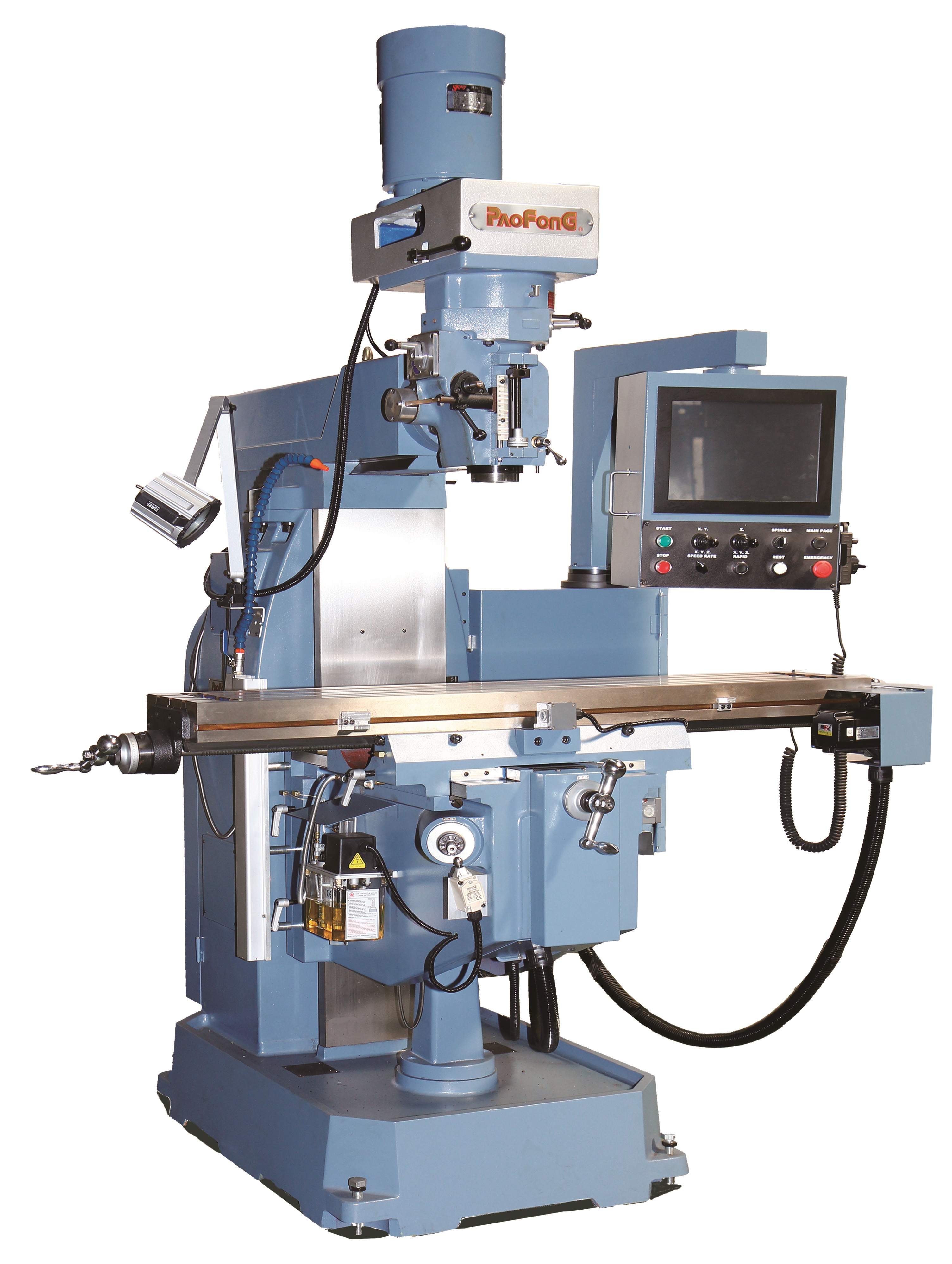

YEONG CHIN MACHINERY INDUSTRIES CO., LTD.

Product Description :

Most Popular High Performance NSV106AS is well suited for superior surface finishing works, specially in automotive, job shop and electronics industries. ■ Large delta machine column and base ensure the highest stability during high speed movement■ High precision roller type guideways on all 3 axes■ High precision linear guideway with 6 slide blocks on X-axis■ High performance YCM in-house designed spindle with low vibration to achieve excellent finish

FUI JET TECH CO., LTD

Product Description :

The zero-point positioning system is a normal clamping mechanism, which is opened during ventilation and the air pressure is cut off. When the zero-point positioning system is ventilated, the pressure will pass through the compressed spring inside the piston, causing the piston to rise, and the steel balls can retreat toward the water pump. When the air source is turned off, the spring will push back the piston, and the piston handle will The steel ball is pushed toward the middle, causing the ladder bolt to

ASIA PACIFIC ELITE CORP.

Product Description :

G800T,a single machine completes all cutting processing.

The APEC 5-axis mill-turn machining center G800T is built with a vertical structure to tackle the limitations faced by traditional lathe machining. After turning, it seamlessly transitions into milling without having to move the workpiece, cutting down on time and human errors. This means you can complete the job in one go without switching processes, leading to a more efficient and modern machining experience.