Theme

Digital Transformation

Green Transformation

DYNA COMPRESSOR CO., LTD.

Product Description :

PM MOTOR

With powerful driving core, it is more energy-saving and energy-saving

The biggest advantage of permanent magnet variable frequency air compressor is energy saving by 10%~35% in average. It depends on the working condition of the air compressor and the setting of the frequency converter.

If the air consumption fluctuates, the energy-saving effect is better. Using a high-efficiency and energy-saving control system, the starting current is small and reduce the impact on the motor and electrical components; the life of the motor is extended, and the impact on the equipment and machinery is relatively reduced.

ZHAO YI HSIN INDUSTRIAL CO., LTD.

Product Description :

Providing clean compressed air without energy consumption

No power required

Applying characteristics of compressed air, hydromechanics and physical principles to design internal structure.

Consumable-free, maintenance-free

Exclusive patented structural design can separate moisture from compressed air without consumables.

Efficiency of air drying and moisture filtration: 99%

Patented high efficiency water-cooled heat exchanger and special air-water separation structure.

High quality, durable, and longevity up to 10 years

No compromise on quality, the product is made in Taiwan.

No electronic and other energy-driven device

Suitable for those who have special needs for compressed air.

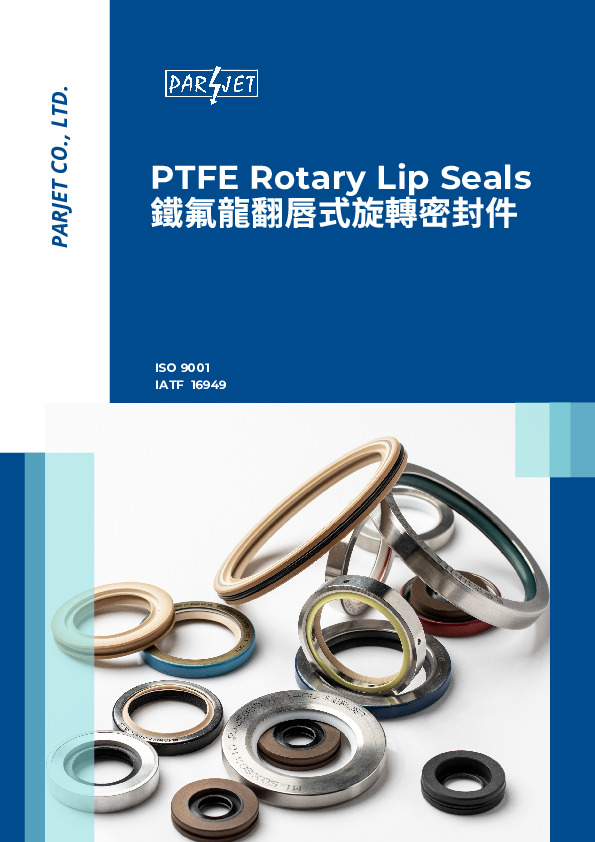

Parjet Co.,Ltd.

Product Description :

HiPerLip®, also known as PTFE Shaft Seal, is a rotary shaft seal with a PTFE sealing lip and metal casing. The rotary seal is ideal for sealing high-speed rotary applications with very low friction and minimal power draw to achieve better performance, higher response, and precision. Thanks to excellent PTFE compounds and the unique sealing lip construction, the PTFE rotary lip seal with metal case provides superior performance over conventional rotary oil seals, especially in high rotary, poorly lubricated, highly corrosive, high temperatures, and other extreme working environments. Typical temperatures range from -60°C to 200°C (-76°F to 390°F), and shaft speeds up to 30 m/s (5,905 fpm) for low pressure applications.