Theme

Digital Transformation

Green Transformation

CLAMPTEK ENTERPRISE CO., LTD.

Product Description :

Clamptek’s CLF5H series designed with connecting rod structure which can operate conveniently. CLF5H series can also reduce the interference with loading and unloading operation, because when CLF5H series is in the unclamping state, it’s clamping arm can be put lower than holding position.

Clamptek’s CLF5H series’ clamping arm is very flexible. By reducing the interference of the surrounding equipment, CLF5H series can save lots of working space.

Clamptek’s CLF5H series equipped with special dust proof design and high sealing, which can prevent the cutting chips and coolant to infiltration. Therefore, CLF5H series can be used in more severe conditions.

Please kindly check the suggested operating pressure as below,

Max. operating pressure: 70 kgf/cm2

Min. operating pressure: 10 kgf/cm2

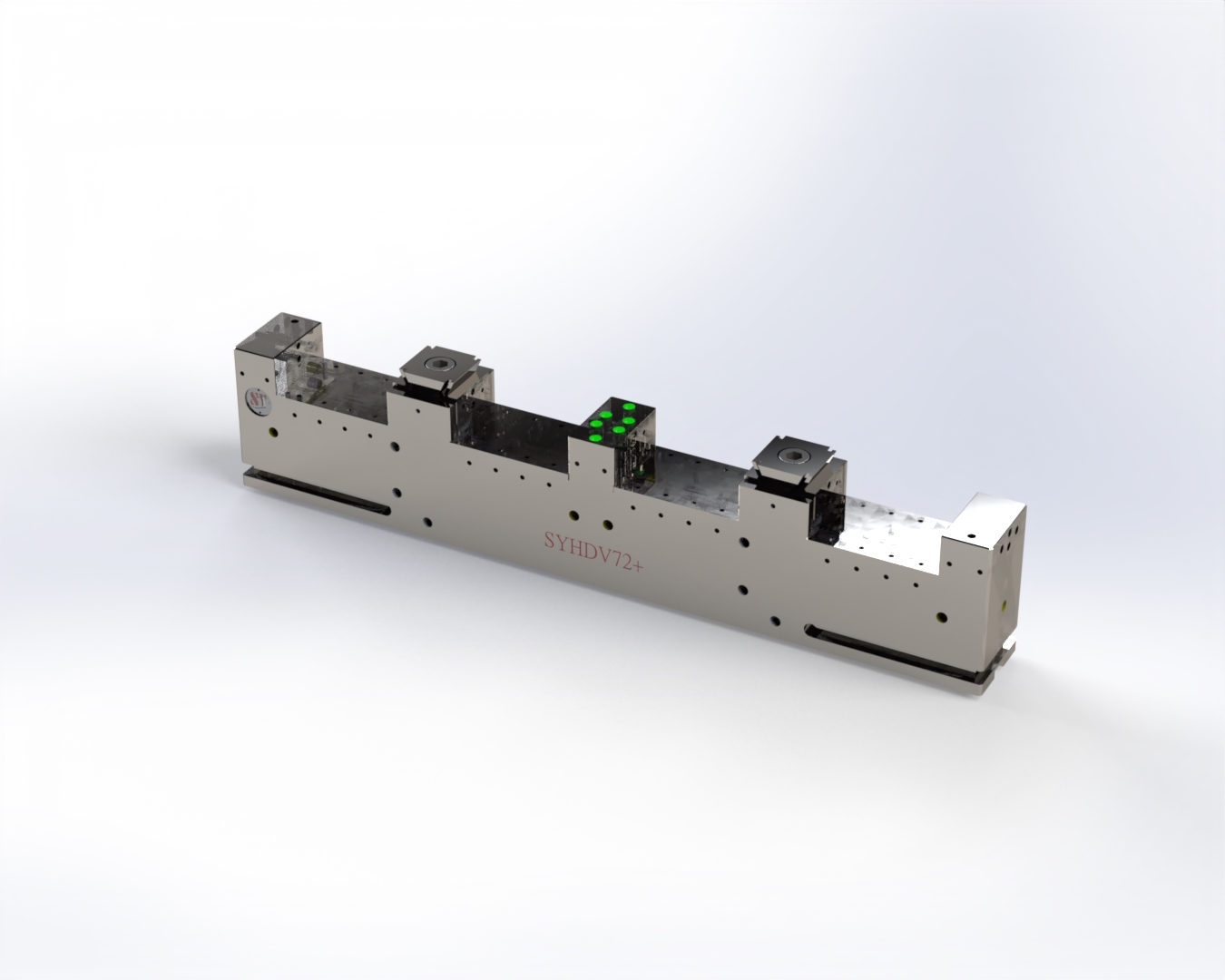

HOMGE MACHINERY IND. CO., LTD.

Product Description :

1) Patented stud bolt seat design can efficiently calibrate the clamping center.

2) It is recommended to operate with a Master Plate on a five-axis machine.

3) Compatible with Robotic Arms.

Product Data:

1.Vise body is made of High quality Steel (S50C) and its slideways gone through high-frequency hardening to achieve HRC50, which makes the whole part durable.

2.Detachable jaws are made of High quality Tool Steel (SCM440) and gone through carburizing to achieve HRC55. Since both sides are fixed size and able to be used as a datum, users can reverse them to increase clamping range.

3.The vise's clamping force can achieve 1300KG, the repeatability positioning precision of its clamping center is within ±0.02mm.

4.Users can calibrate the clamping center of vise by adjusting the screws on both ends.

5.The 45° dovetail structure with teeth on the upper jaw ensures the bottom of the workpiece to be firmly clamped.

6.Applications: precision machining of four-axis, five-axis, CNC indexing table and vertical and horizontal CNC milling machines.

CLAMPTEK ENTERPRISE CO., LTD.

Product Description :

🔹The optimized design of the accessories of CHA / CHA-P series makes the structure more compact and increases the product strength.

🔹 CHA / CHA-P series equipped with special dustproof design and have high sealing performance.

🔹The designation of high anti-torque makes the durability long.

🔹 Max. operating pressure:70 kgf/cm²

Min. operating pressure:15 kgf/cm²

🔹Double acting

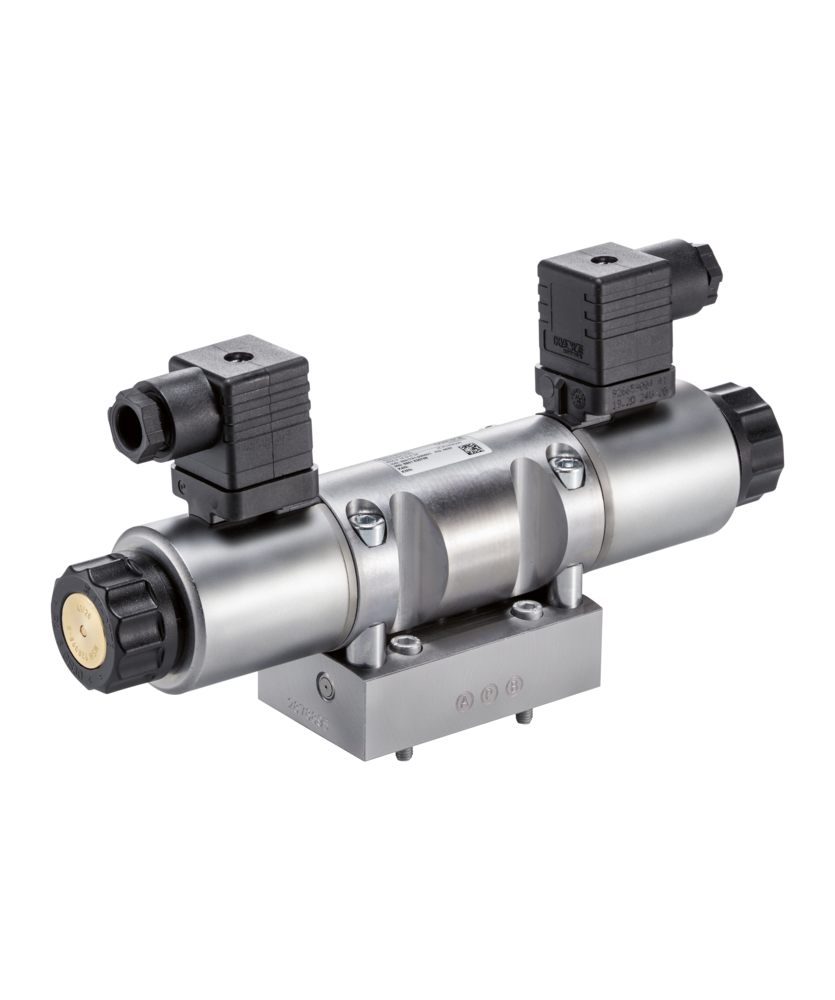

HAWE Hydraulik Singapore Pte. Ltd. Taiwan Branch

Product Description :

Directional seated valves are a type of directional valve. As cone valves they are tightly sealed, with zero leakage in the closed state.

The directional seated valve type ROLV is available as a 3/2, 4/2 or 4/3-way directional seated valve with different plug types. The patented assembly consists of two parts: a round basic valve with the valve inserts, and an adapter plate which can be designed for manifold mounting with nominal size NG 6 as the

standard connection pattern, or for direct pipe connection.

Additional elements such as a check valve, a restrictor (on the consumer side) and/ or restrictor check valves can be integrated, depending on the functional requirement and adapter plate. The type ROLV can be combined in the valve bank type BA with other types of valves.

Features and benefits

■ Dirt-resistant design with high switching reliability

■ Interchangeable solenoid for greater flexibility and easy servicing

Intended applications

■ Machine tools (cutting and non-cutting)

■ Clamping tools, punching tools, fixtures

■ Testing machinery

■ Wind turbines

ASMITH MANUFACTURING COMPANY

Product Description :

Spring Loaded Draw Latch |The proposed load of 22~50 kgf.

Both sides spring design with compression function.

Standard Lock-hole can using with lock. Suitable for vibration equipment.

Smooth surface, excellent brushed finish appearance, in accordance with RoHS.

The draw latch is including the horizontal keeper [CS(T)-0120-2 or CS(T)0130-2], if you need another type keeper then you can reference the below "Accessories".

➤Material: SUS304(Stainless steel)-vibration ground and brushed finish, SPCC(cold-rolled steel)-zinc plated

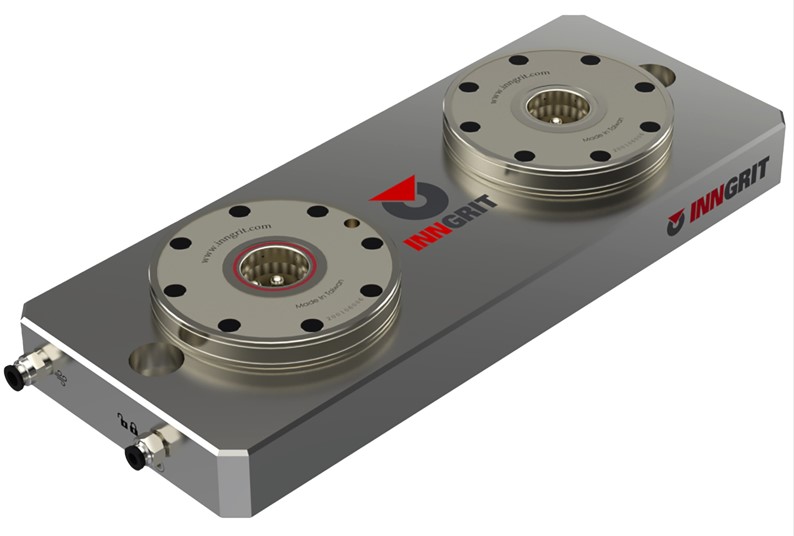

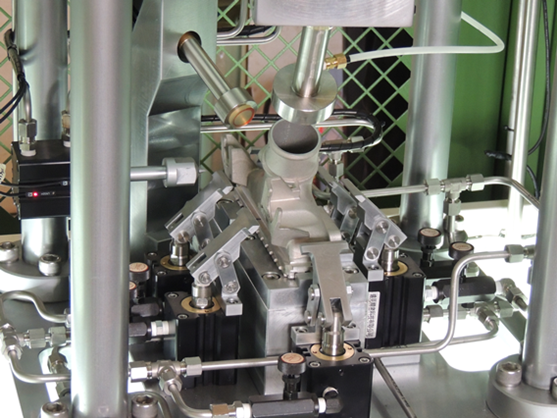

FARSIGHT PRECISION CO., LTD.

Product Description :

Finished leaking testing just only 1 minute !!!

Leaking Testing Machine (Pressure testing machine)

◎ Our company could according to products request of

condition of client, design and manufacturing dry type,

wet type or dry-wet 2 ways in one leaking testing

machine.

◎ 2 workpiece finished at the same time.

◎ The client can select the "COSMO", "FUKUDA" or other

leaking testing instrument, and install user-interface

system.

◎ Attach computer storage, calculation and network output

etc...

◎ The equipment could exchange the workpiece quickly.

◎ The equipment could exchange fixtures for other

workpiece.

◎ It can set the water tank in time.

◎ The client can option to mark on workpiece with laser or

punching.

CLAMPTEK ENTERPRISE CO., LTD.

Product Description :

*High supporting force

CSP-P/ CSP-K increases the holding force between the piston rod and the inner jacket to arise the higher supporting force.

*Coolant cleaning measures

In order to prevent the malfunction from the intrusion of high-pressure coolant and the cutting dust entering the internal structure, air can be cleaned at the breathing port when replacing the workpiece. Air cleaning requires a dedicated air circuit. (recommended cleaning pressure is 0.3 - 0.5MPa).

*Universal piping base

CSP-P/ CSP-K piping base is interchangeable, which can be installed with other low-pressure cylinders in the same specifications.