Theme

Digital Transformation

Green Transformation

YANMECH Industrial Co., Ltd.

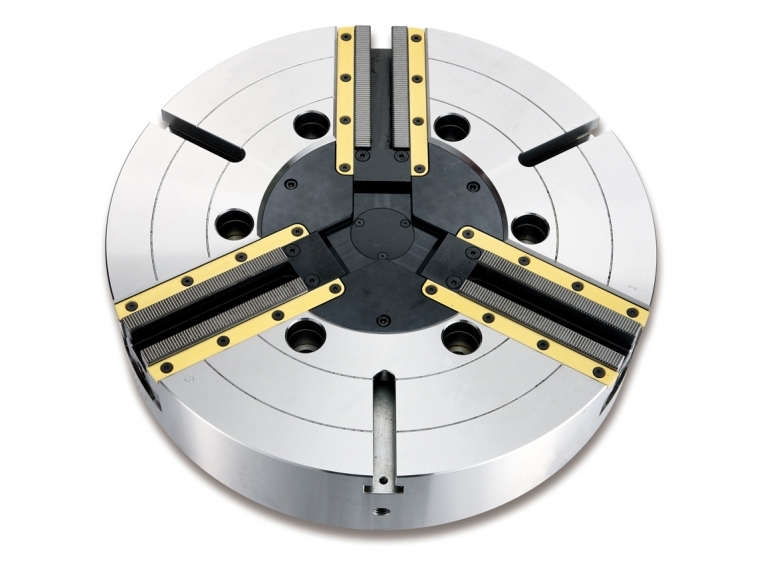

Product Description :

Product Features:Different from the previous positioning of the box jaws by the positioning key, this product will positioning parts into the product, can be locked with the screw lock or unlock, can avoid the traditional positioning the possibility of flying out in the rotation and the advantage of easy assembly.

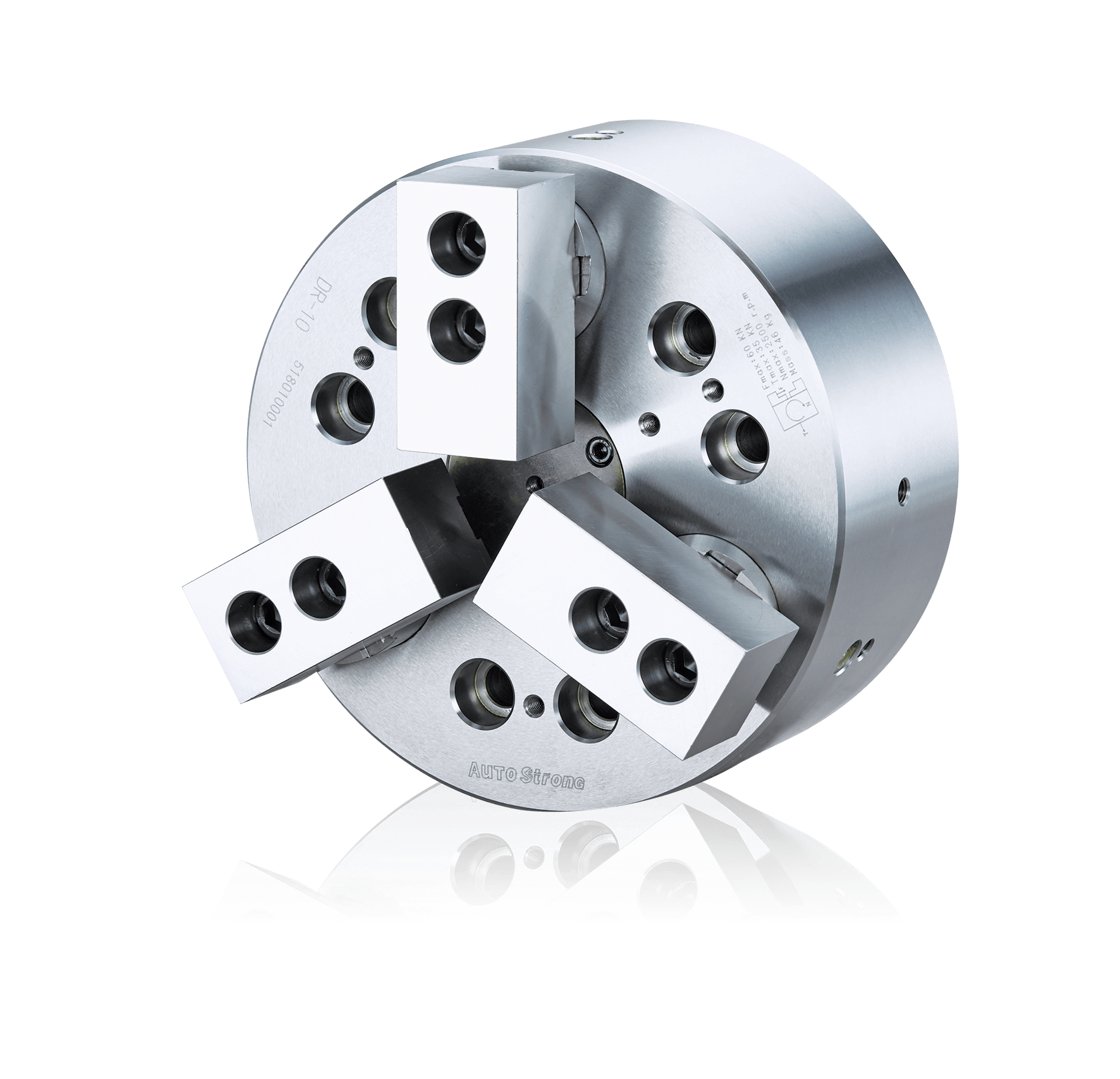

YANMECH Industrial Co., Ltd.

Product Description :

【A Series:】

1. The jaw can be individually operated, and irregularly shaped workpieces can be clamped.

2. Install side strips and chips cover sealed base jaw to prevent chips and coolant ingress.

【D Series:】

1. Install side strips and chips cover sealed base jaw to prevent chips and coolant ingress.

2. Adapter Plates can be selected.

3. The base jaw is lower than the body surface and can be used for multipurpose.

4. Alternative spindle adaptors:

ASA or DIN adaptors can be supplied as requested.

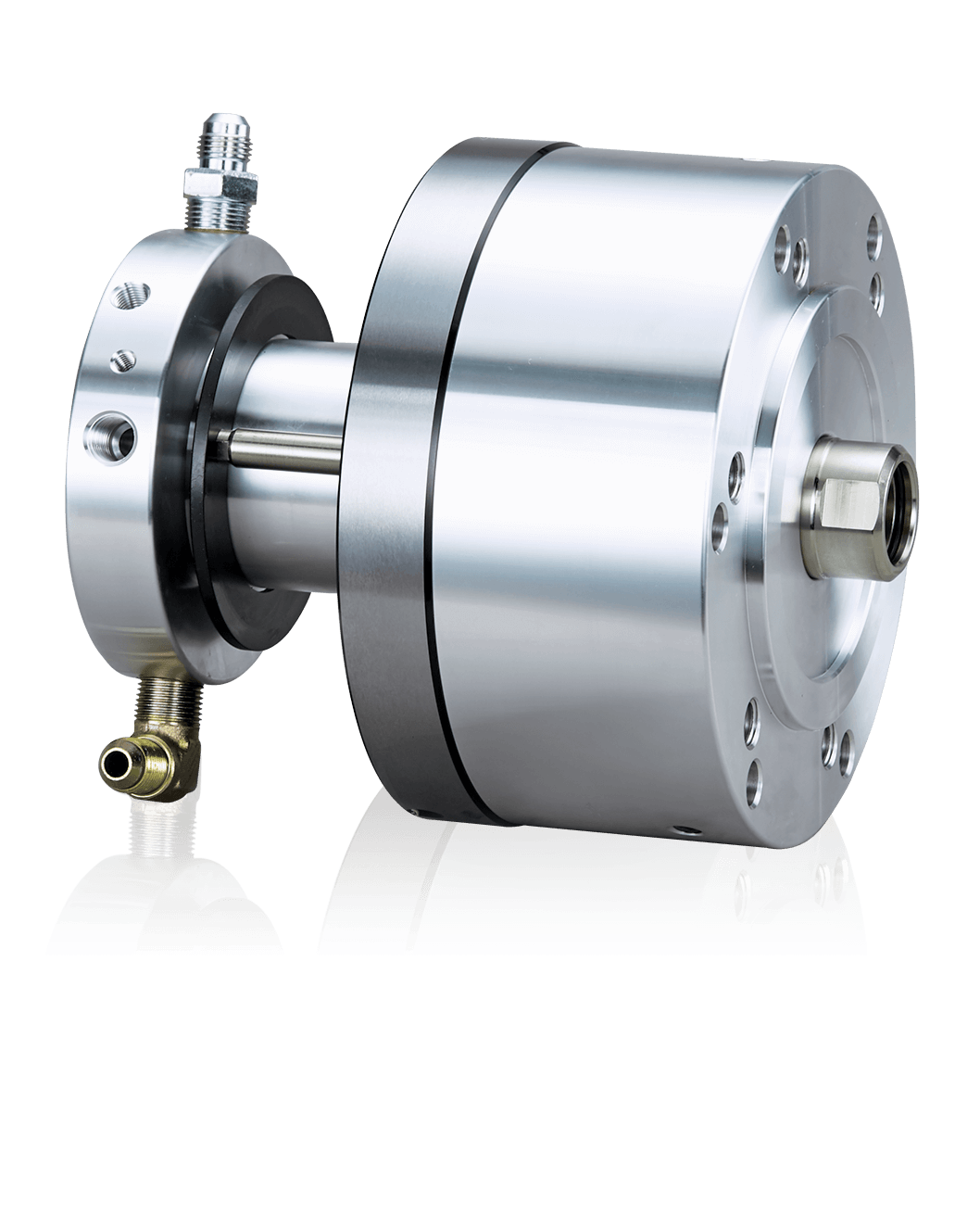

DI CHUN IRON WORK CO., LTD.

Product Description :

Drawdown power chuck feature of radial clamping will lead to almost no workpiece uplifting displacement; for machining casting and forging part:

1. For the clamped workpiece is oppressed to the surface, chucks are suitable for heavy machining.

2. Chuck Actuators with the cylindrical structure is durable and ensures high clamping repeatability.

3. Accurate self-centering and pull back features are adequate or precise length control machining requirements.

FARSIGHT PRECISION CO., LTD.

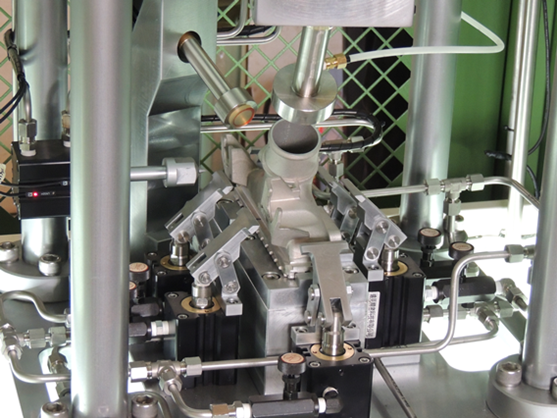

Product Description :

Finished leaking testing just only 1 minute !!!

Leaking Testing Machine (Pressure testing machine)

◎ Our company could according to products request of

condition of client, design and manufacturing dry type,

wet type or dry-wet 2 ways in one leaking testing

machine.

◎ 2 workpiece finished at the same time.

◎ The client can select the "COSMO", "FUKUDA" or other

leaking testing instrument, and install user-interface

system.

◎ Attach computer storage, calculation and network output

etc...

◎ The equipment could exchange the workpiece quickly.

◎ The equipment could exchange fixtures for other

workpiece.

◎ It can set the water tank in time.

◎ The client can option to mark on workpiece with laser or

punching.

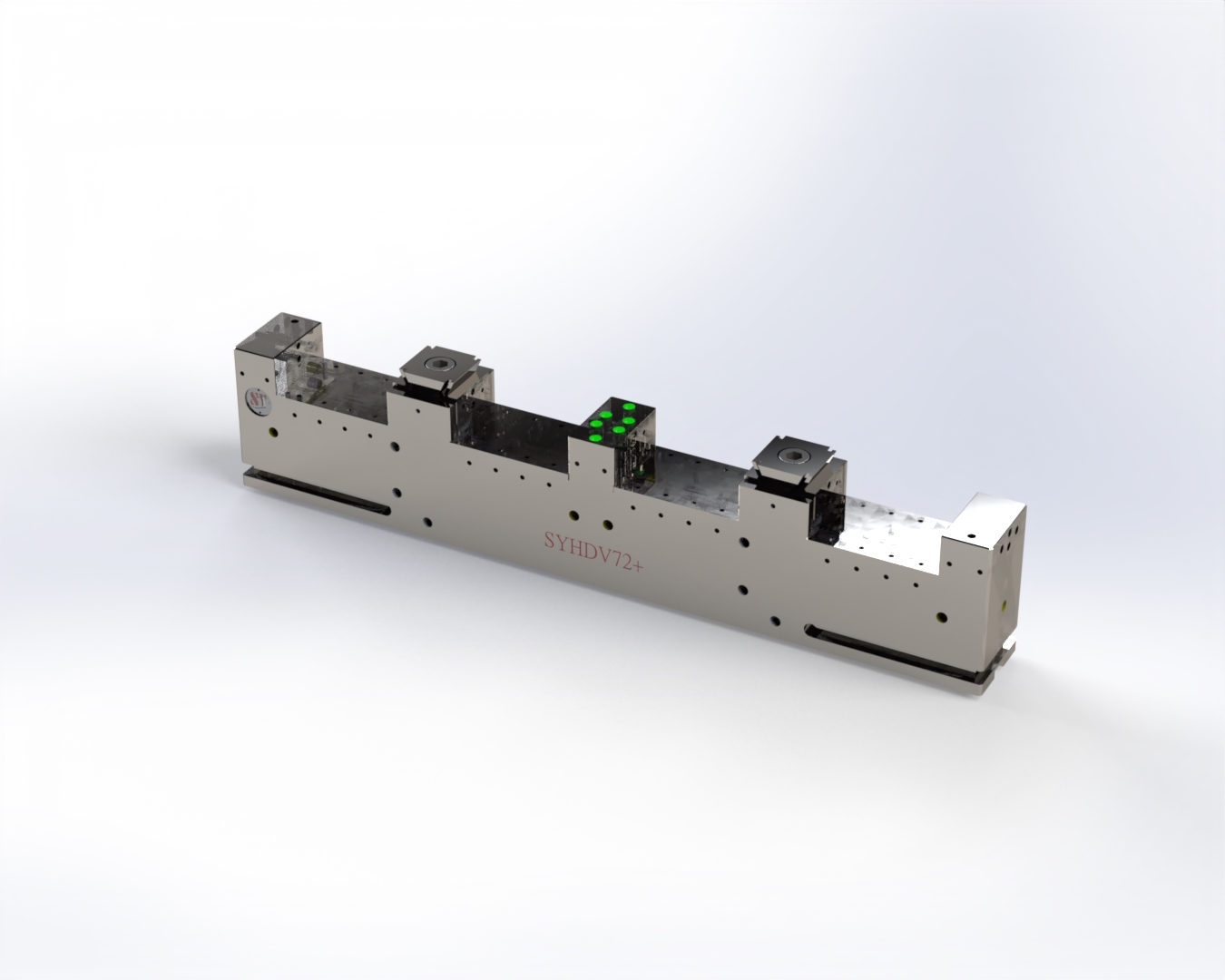

HOMGE MACHINERY IND. CO., LTD.

Product Description :

1) Patented stud bolt seat design can efficiently calibrate the clamping center.

2) It is recommended to operate with a Master Plate on a five-axis machine.

3) Compatible with Robotic Arms.

Product Data:

1.Vise body is made of High quality Steel (S50C) and its slideways gone through high-frequency hardening to achieve HRC50, which makes the whole part durable.

2.Detachable jaws are made of High quality Tool Steel (SCM440) and gone through carburizing to achieve HRC55. Since both sides are fixed size and able to be used as a datum, users can reverse them to increase clamping range.

3.The vise's clamping force can achieve 1300KG, the repeatability positioning precision of its clamping center is within ±0.02mm.

4.Users can calibrate the clamping center of vise by adjusting the screws on both ends.

5.The 45° dovetail structure with teeth on the upper jaw ensures the bottom of the workpiece to be firmly clamped.

6.Applications: precision machining of four-axis, five-axis, CNC indexing table and vertical and horizontal CNC milling machines.