Theme

Digital Transformation

Green Transformation

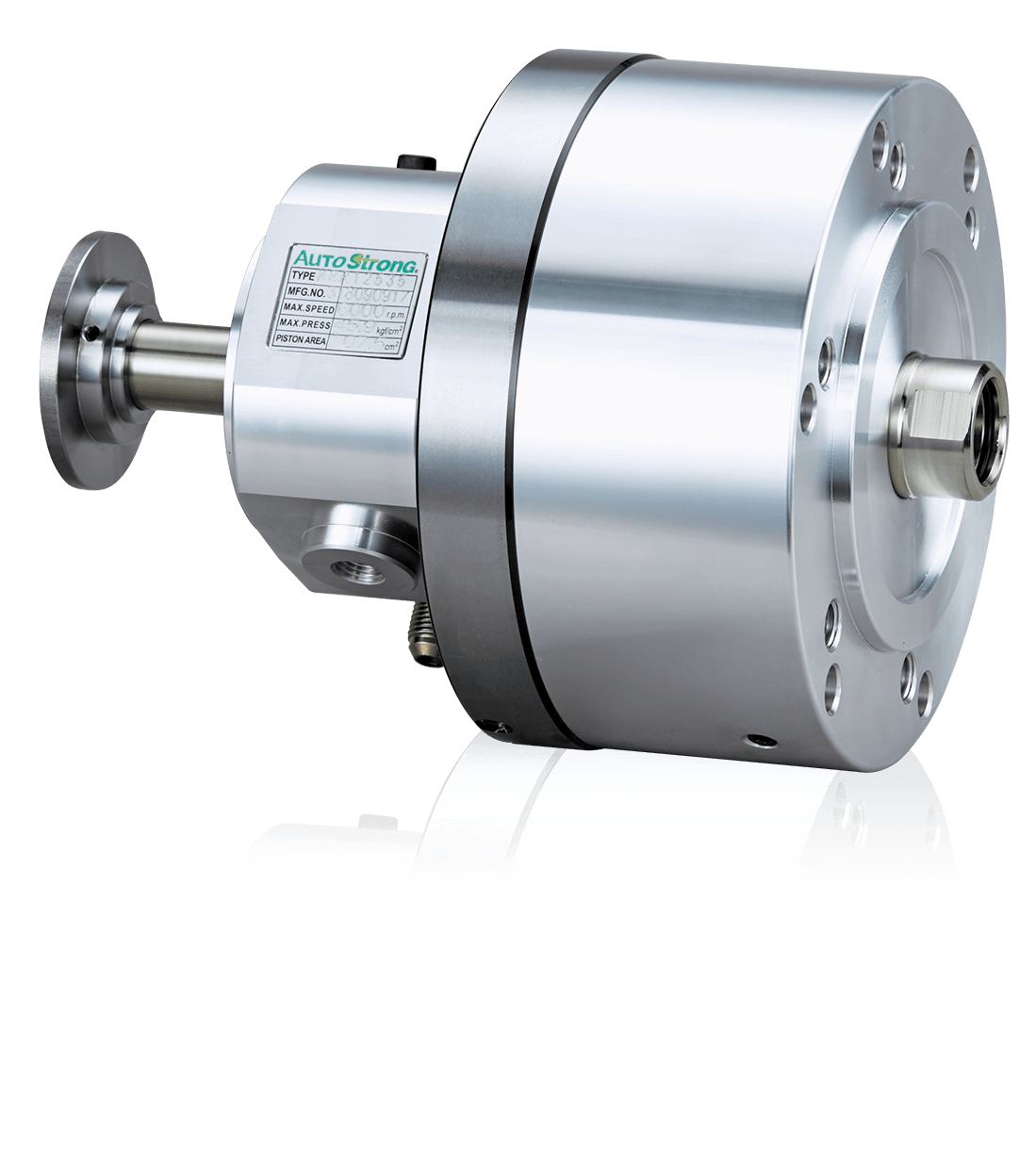

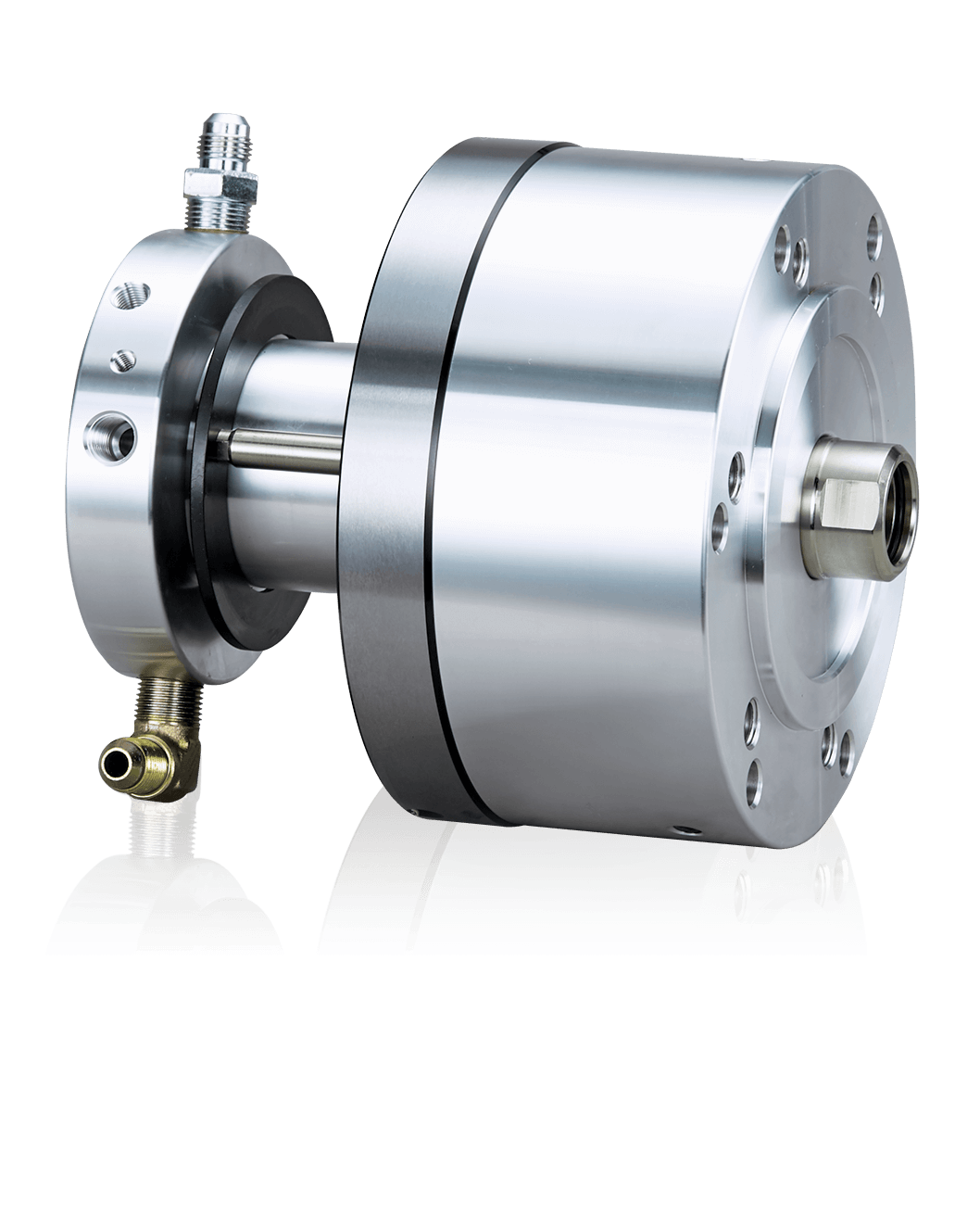

CLAMPTEK ENTERPRISE CO., LTD.

Product Description :

🔹The optimized design of the accessories of CHA / CHA-P series makes the structure more compact and increases the product strength.

🔹 CHA / CHA-P series equipped with special dustproof design and have high sealing performance.

🔹The designation of high anti-torque makes the durability long.

🔹 Max. operating pressure:70 kgf/cm²

Min. operating pressure:15 kgf/cm²

🔹Double acting

Taiwan TeamA Tech. Co., Ltd.

Product Description :

建立於 Fuse 1 成功的基礎下,formlabs 推出進階款選擇性雷射燒結(Selective Laser Sintering, SLS)3D列印機 Fuse 1+30W 及粉末回收系統 Fuse Sift。提升2倍的列印速度,在3倍的雷射功率下,實現真正快速的企業內部生產!使用尼龍粉末燒結技術,搭載高轉換效率的「掺鐿光纖雷射」與專利研發技術「表面盔甲技術」(Surface Armor),讓用戶獲得更穩定的列印品質與更堅固的物件表面。

Formlabs一直以來對於人體健康與環境保護都十分重視,Fuse 1在運轉時,通過國家室內空氣品質標準,其中包含甲醛、TVOC、PM2.5、及PM10…等揮發性有機物測試,列印中不會產生有害氣體,另外也配有完善的粉末回收系統Fuse Sift。除了能將舊粉末過濾後重複使用,還可自動化混合新舊粉、自行選擇刷新比例,減去繁雜的手動混合程序,不僅環保不浪費,更能以最低耗損帶來最高產值。

【Fuse 1+30W 六大特色】

1. 16.5*16.5*30cm 超大列印空間

2. 掺鐿光纖雷射穩定的光束品質

3. 專利Surface Armor技術物件更堅固

4. 粉末回收率高、擁有自動粉末混合系統

5. 兼具高韌性、耐高溫、耐衝擊的多元性能列印材料

6. 繁體中文切片軟體PreForm超好用

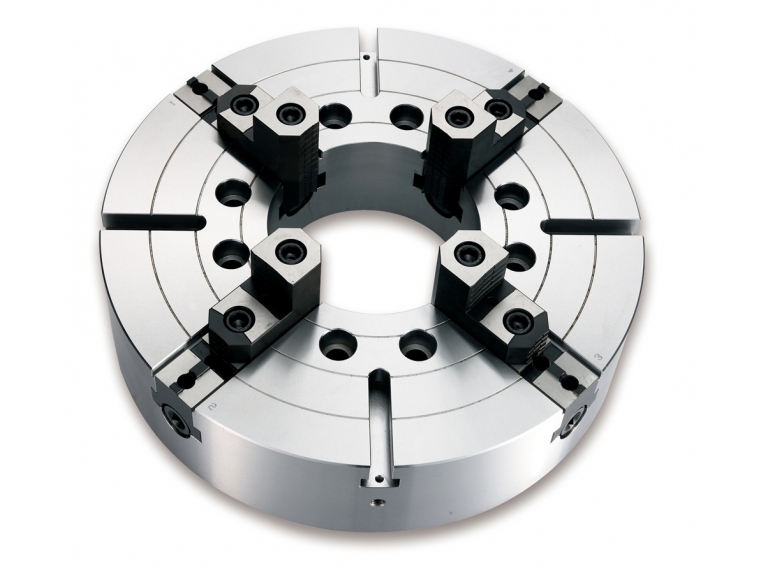

YANMECH Industrial Co., Ltd.

Product Description :

【J Series:】

1. Adapter Plates can be selected.

2. Install side strips and chips cover sealed base jaw to prevent chips and coolant ingress.

3. The jaw can be individually operated, and irregularly shaped workpieces can be clamped.

4. Special specifications can be customized.

【L Series:】

1. Adapter Plates can be selected.

2. The jaw can be individually operated, and irregularly shaped workpieces can be clamped.

3. Special specifications can be customized.

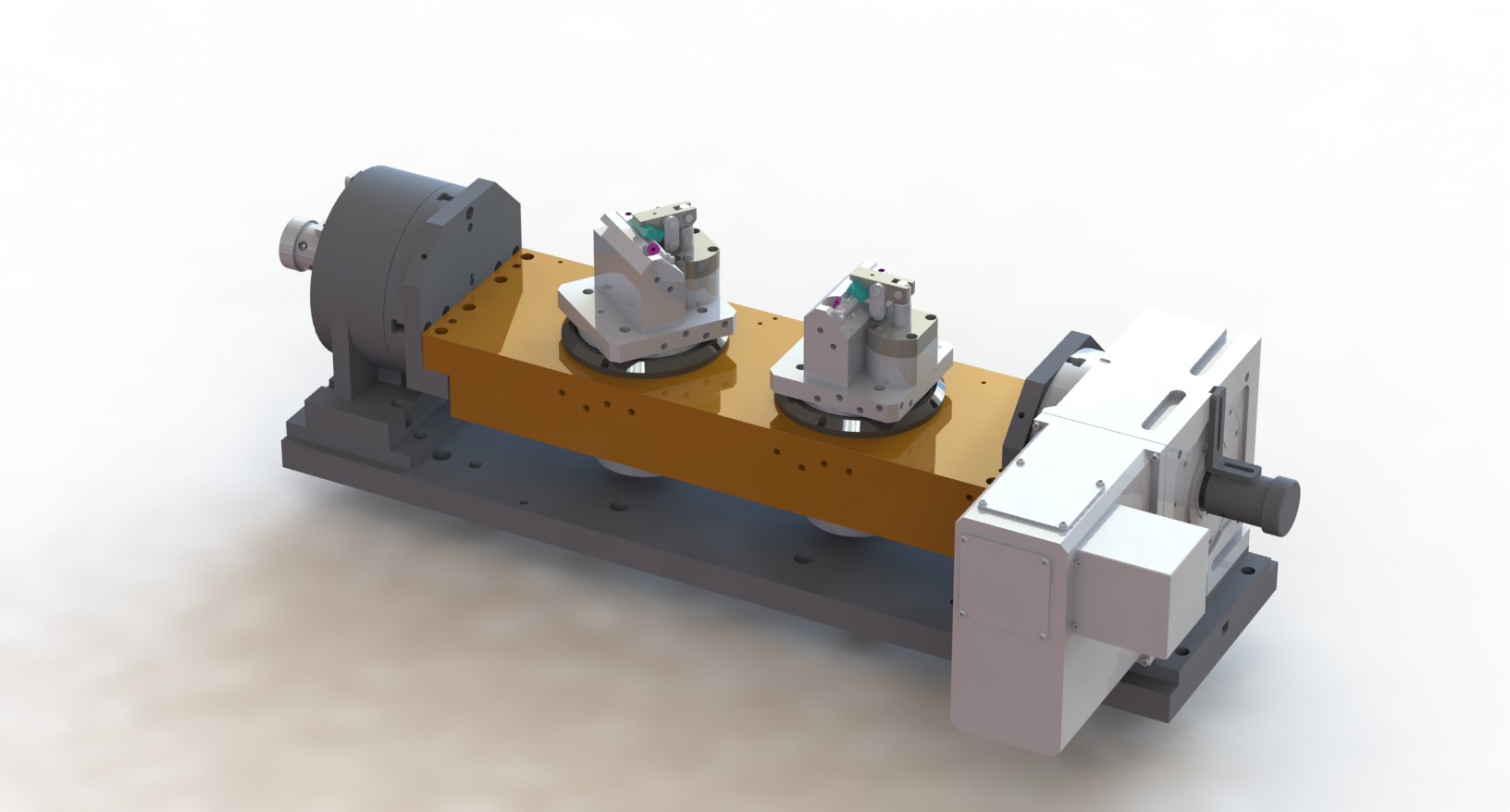

HOMGE MACHINERY IND. CO., LTD.

Product Description :

1) Patented stud bolt seat design can efficiently calibrate the clamping center.

2) It is recommended to operate with a Master Plate on a five-axis machine.

3) Compatible with Robotic Arms.

Product Data:

1.Vise body is made of High quality Steel (S50C) and its slideways gone through high-frequency hardening to achieve HRC50, which makes the whole part durable.

2.Detachable jaws are made of High quality Tool Steel (SCM440) and gone through carburizing to achieve HRC55. Since both sides are fixed size and able to be used as a datum, users can reverse them to increase clamping range.

3.The vise's clamping force can achieve 1300KG, the repeatability positioning precision of its clamping center is within ±0.02mm.

4.Users can calibrate the clamping center of vise by adjusting the screws on both ends.

5.The 45° dovetail structure with teeth on the upper jaw ensures the bottom of the workpiece to be firmly clamped.

6.Applications: precision machining of four-axis, five-axis, CNC indexing table and vertical and horizontal CNC milling machines.

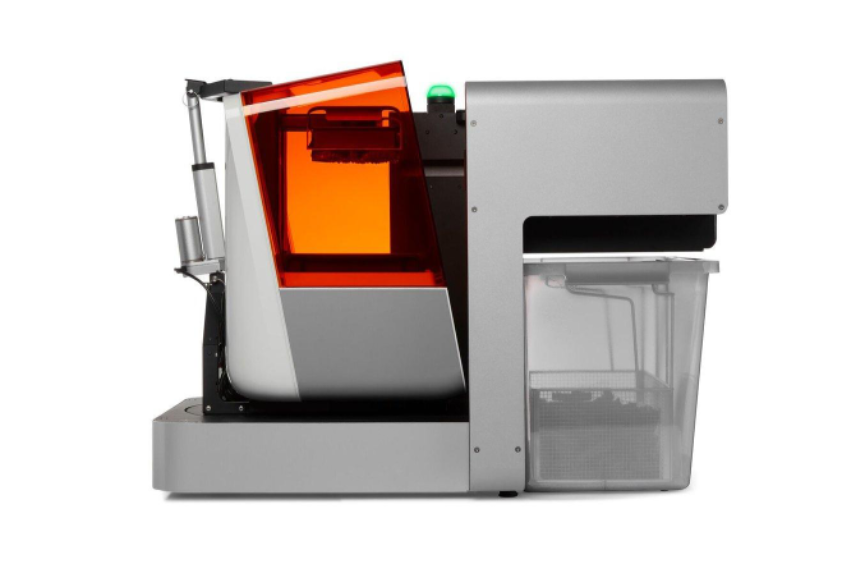

Taiwan TeamA Tech. Co., Ltd.

Product Description :

擺脫時間、地點的限制,利用自動化生產解決方案再創生產率新高!無需人工操作,24小時不停機生產,製造大量、高質量物件,使用 Formlabs 自動化解決方案(包含 Form Auto、群機管理和高容量樹脂系統),在 3D 列印工作流程中更高效的工作並重新定義生產能力。在不增加列印機管理複雜性的情況下擴展您的零件生產。從任何地方點擊發送,Formlabs 自動化解決方案將處理剩下的工作流程。

【最大程度地降低每個零件的成本,節省高達 80% 的勞動力】

在 Form Auto 出現之前,每個完成的零件都需要在後處理之前從成型平台上手動移除。Form Auto 透過將 Formlabs 獲得專利的「快速剝離技術」與「成型平台 V2 」結合使用,完全自動化地移除零件。蒐集的零件被放置在防紫外線的容器中,無縫批量轉移到 Form Wash。

【24 小時不間斷 3D 列印,無需額外程序】

Form Auto 自動化生產系統旨在不閒置列印機、不讓列印物件在序列中等待,無論現場是否有操作人雃,Form Auto 始終準備好開始下一次列印。 隨時隨地構建多列印機群,從辦公室點擊「列印」,立即在生產間開始生產。透過群機管理中的圖像和影片遠程監控和審查成品零件,設備內相機在完成時捕獲每個列印件來保存每個部分的記錄。