Theme

Digital Transformation

Green Transformation

PRAISE PRECISION IND. CO., LTD.

Product Description :

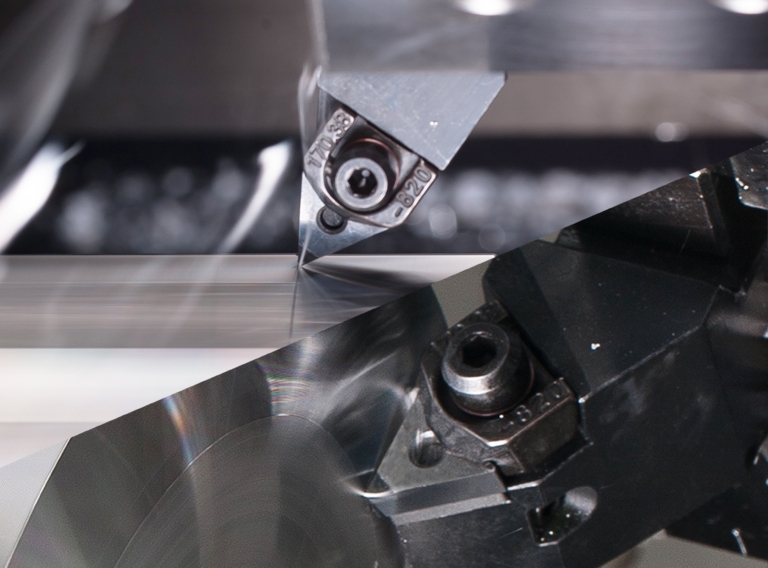

NEW PRODUCT- CUTTING KNURLING TOOLS USED ON LATHE

Method of forming knurling

1. Press forming(Form knurling)

Press knurling tool directly to workpiece in turning on the lathe

to form the patterns. Pressure is applied to the lathe spindle, and the outside diameter of workpiece will become bigger

2. Cutting forming(Cut knurling)

The knurling tool is applied to workpiece just like cutting, less pressure

to lathe spindle and less machining resistance, forming a clear patterns, the best choice for using on CNC lathes

SONG GIA INDUSTRIAL CO., LTD.

Product Description :

Hole deflection within 0.004

■Choose Machine : Star SR-20RIV SR-32J

■Detailed specifications

△Speed ratio :1:1

△Maximum speed : 6000RPM

△Tool clamping : ER16M/ER11M

△Reference code :0M155

https://www.songgia.com.tw/en/products/3-spindle-double-drilling-milling-unit-stra2b3201

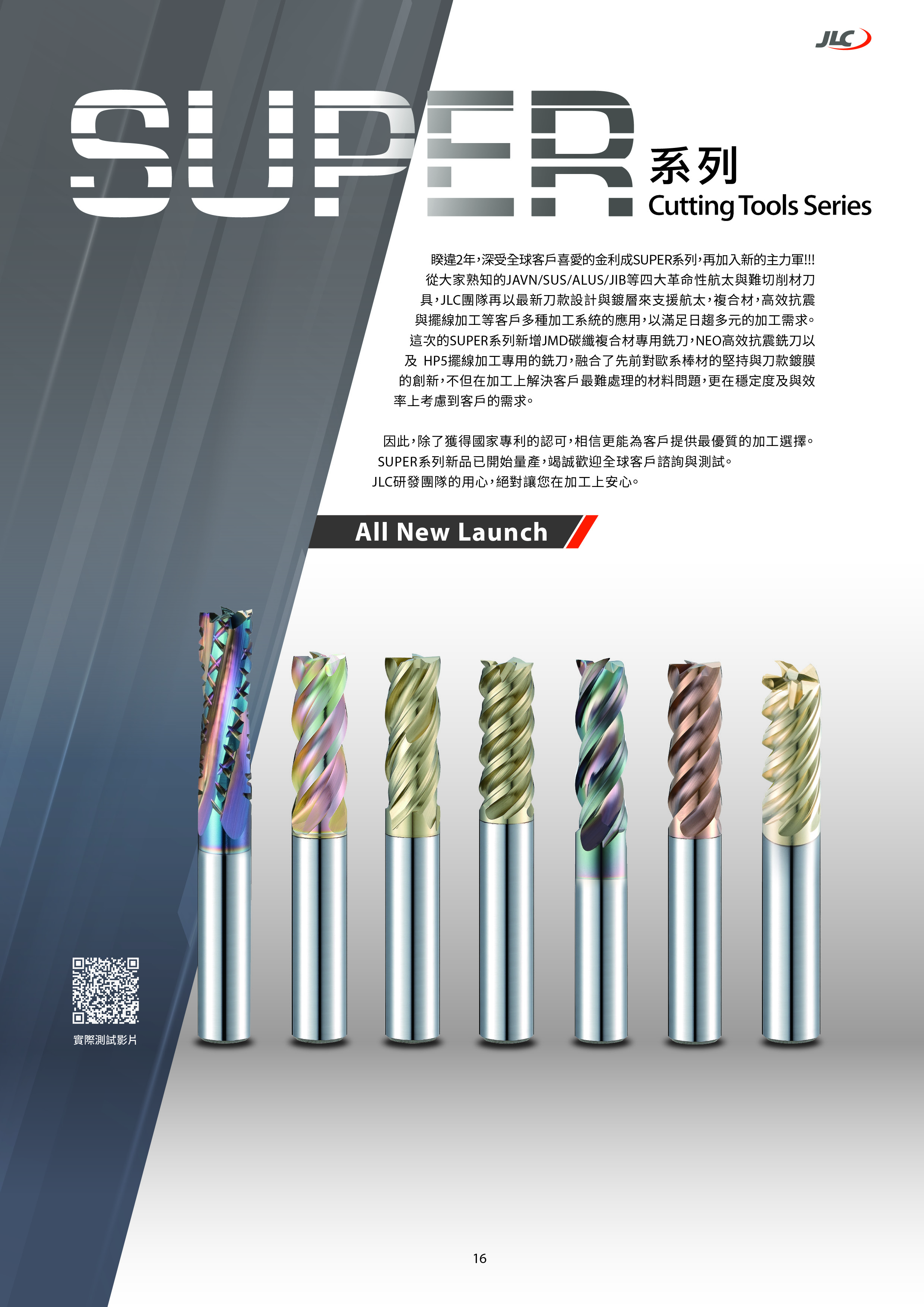

JIN LI CHENG CUTTING TOOL CO., LTD.

Product Description :

睽違2年,深受全球客戶喜愛的金利成SUPER系列,再加入新的主力軍!!!

從大家熟知的JAVN/SUS/ALUS/JIB等四大革命性航太與難切削材刀具,JLC團隊再以最新刀款設計與鍍層來支援航太,複合材,高效抗震與擺線加工等客戶多種加工系統的應用,以滿足日趨多元的加工需求。

這次的SUPER系列新增JMD碳纖複合材專用銑刀,NEO高效抗震銑刀以及 HP5擺線加工專用的銑刀,融合了先前對歐系棒材的堅持與刀款鍍膜的創新,不但在加工上解決客戶最難處理的材料問題,更在穩定度及與效率上考慮到客戶的需求。因此,除了獲得國家專利的認可,相信更能為客戶提供最優質的加工選擇。

SUPER系列新品已開始量產,竭誠歡迎全球客戶諮詢與測試。

JLC研發團隊的用心,絕對讓您在加工上安心。

MONGTEC PRECISION INC.

Product Description :

BODY

Re-designed main body to improve rigidity and reduce vibration. Specially treated corrosion resistant steel body.

Bearings

Angular contact preloaded ball bearings of precision class P4 / ABEC 9.

Bevel Gears

Gleason computer based calculations for the Gleason cut spiral bevel drive gears with ground teeth in order to guarantee a bigger torque.

Torque and Speed

With Speeder 1:4:32,000 Rpm

(Standard 1:1:6000~12000Rpm)

Max Torque:160Nm

Internal Coolant

Max Pressure:70-100 bar

NINE-9 CUTTING TOOLS CO., LTD.

Product Description :

The “ i-Center ” is a trademark of Nine9,

the developer of the first indexable center drill in the world.(Patented)

Offering an indexable insert system for the 1st time, Nine9’s “i-Center ” design improves your process performance. Shortens set up and center drilling time.Increases tool life and reduces tooling costs.

● High Speed, High Feed Rate

• The special ground insert and rigid holder design facilitate high performance speed and feed rates. For example, drilling alloy steel

at 6000 rpm and feed rate of 600 mm/min. (0.1 mm/rev.).

● Excellent Repeatability

• The positioning repeatability of the insert is within 0.02 mm

(.0008”) in radial direction, thus ensuring conformity to any national

standards.

● Easy Tool Length Setting

• The axial position accuracy of the insert is 0.05 mm (.002”). It is

not necessary to reset the tool length when changing or cutting edge.

● Extended Tool Life

• Coolant can be supplied through the center of the holder to increase performance and extend tool life.

• Insert geometry, grades and coating process are specifically engineered for centering applications.