Theme

Digital Transformation

Green Transformation

JIN LI CHENG CUTTING TOOL CO., LTD.

Product Description :

※ We design and manufacture "speci c industry" tools

with fast delivery and great quality.

※ It can be designed according to the highest standard

and speci cation from customers. Flexible manufacturing

and accept customized tolerance.

※ From concept to nal completion. JLC customized

tools will reduce the cutter exchange labor time and

improve the e

ciency of mass production.

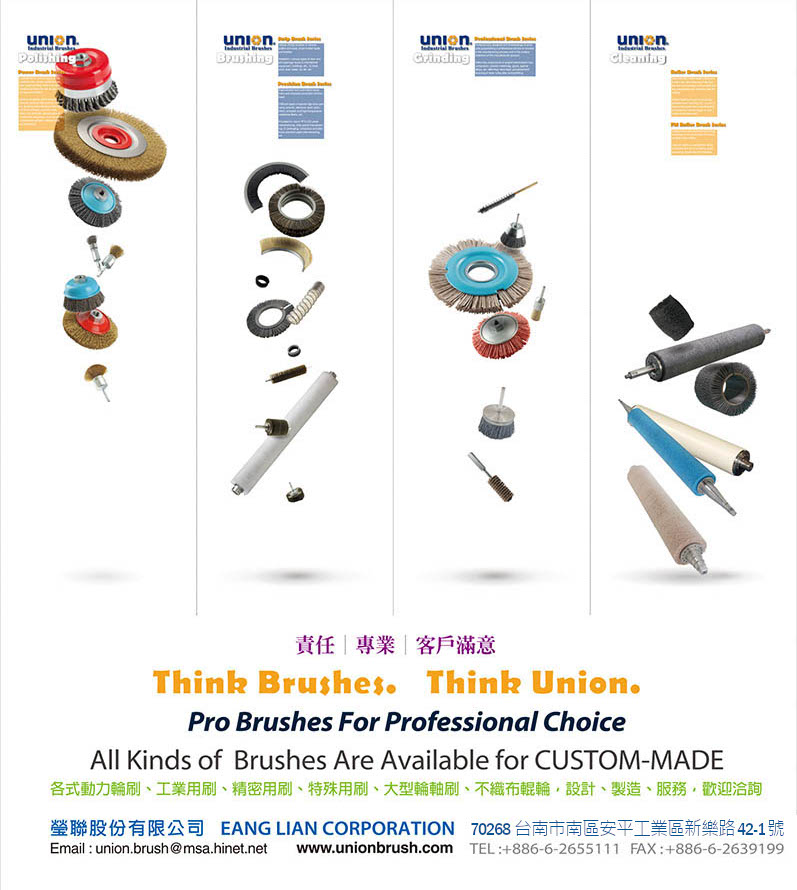

EANG LIAN CORPORATION

Product Description :

刷、磨、拋、洗<br />

專業化的設計能力<br />

多樣化的線材應用<br />

客制化的生產系統<br />

提供客戶製程製品-刷、磨、拋、洗.全方位的解決方案<br />

瑩聯股份有限公司—主要供應各式工業用刷是工業用刷之專業設計製造廠、擁有自有品牌(優利牌),產品適用於各行各業。無論需要刷洗、精細研磨、拋光、輕研磨、重研磨、毛邊去除、深孔加工皆有顯著效果!<br />

<br />

主要產品:<br />

1.動力輪刷系列適用於各型電動及汽動工具.<br />

2.矽砂尼龍研磨刷系列可針對各種表面精細研磨.<br />

3.輪軸刷及板槽刷系列接受各種線材及特殊尺寸訂製<br />

4.鋼鐵業退火酸洗、脫脂清洗、刷磨、清洗等大型刷輥<br />

5.德國技術合作專業生產高科技合成纖維輥適-用於鋼鐵軋片產線之刮油輥、塗油輥、擠水輥、張力輥、轉向輥、擠油輥、擠乾輥、擠壓輥、擠水輥、不織布擠水 輥。 6.各種線材及特殊尺寸可依照客戶需要量身訂製

SONG GIA INDUSTRIAL CO., LTD.

Product Description :

■Choose Machine : Tsugami S205/S206■Detailed specifications

▼Speed ratio :1:1▼Maximum speed : 5000RPM▼

▼Tool clamping : Utilis no.119287▼Angle adjustment : ±20°

▼Reference code : 3281-Y450

https://www.songgia.com.tw/en/products/thread-whirling-unit-tssa545201

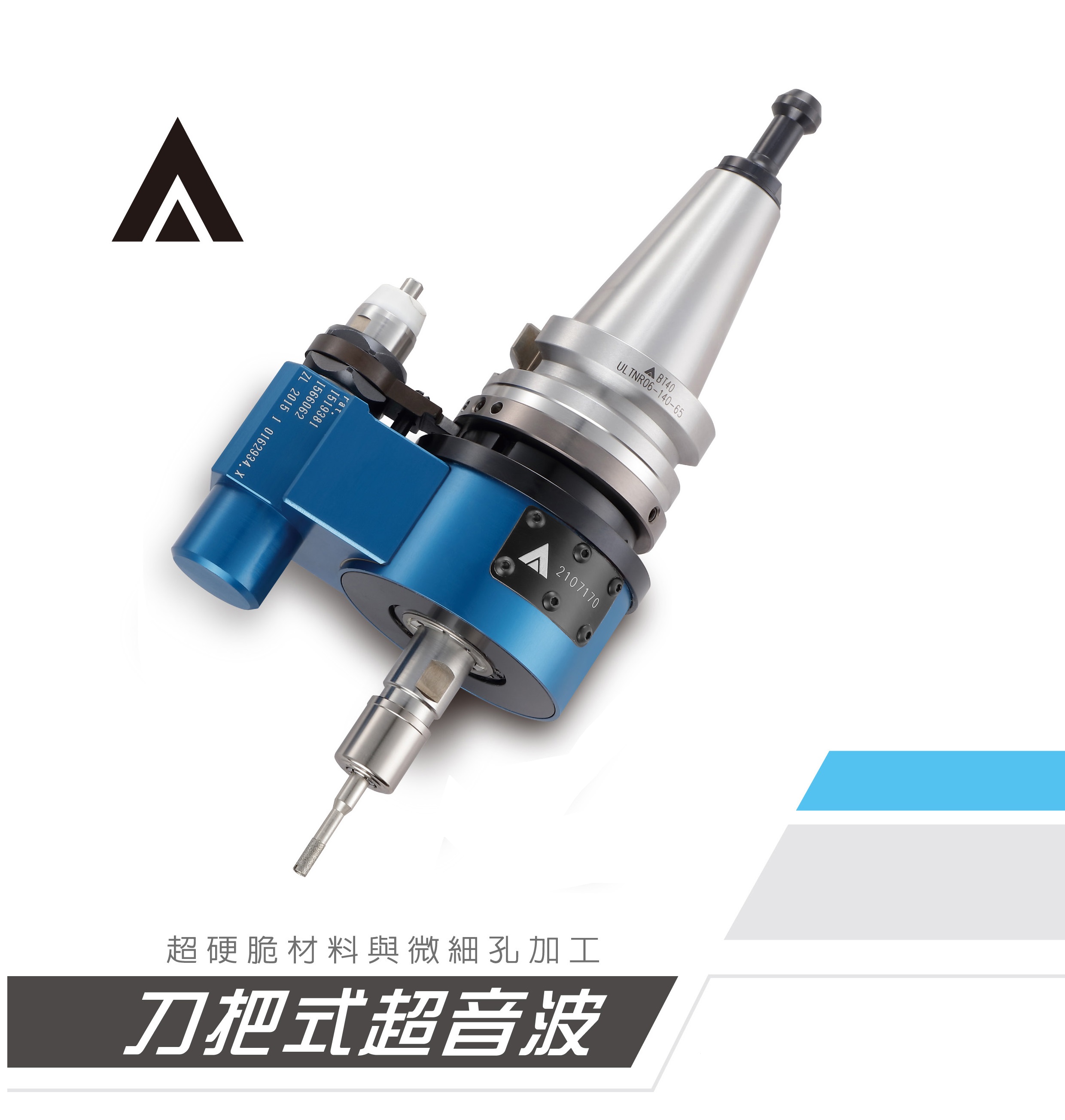

ACROW MACHINERY MFG. CO., LTD.

Product Description :

For Hard brittle material and micro holing drilling / Toolholder support for coolant function /

Clamping accuracy under 5 micro with the spring collets/ No need for special machine /

Easy to operate and install /

Reducing cutting resistance /

Improve surface roughness

CHIN MING PRECISION TOOLS CO., LTD.

Product Description :

PCD DIAMOND CUTTING TOOLS:

★ For high-efficiency machining of silicon carbide(SiC), aluminum oxide(Al2O3), zirconium oxide(ZrO2), quartz(SiO2), Silicon(Si) and carbide.

★ Multi-flute design of end mills reduces cutting resistance and enhances machining efficiency.

★ PCD helix tools can effectively shorten machining time, ensure stable machining accuracy and significantly improve production efficiency.