Theme

Digital Transformation

Green Transformation

MAROX TOOLS INDUSTRIAL CO., LTD.

Product Description :

【External Turning Tools with coolant】

AACLN、AATJN、AATQN、AAWLN、ADCLN、ADDJN、ADDQN、ADTEN、ADTJN、ADTQN、ADVJN、ADWLN、AMCLN、AMDJN、AMTJN、AMVJN、APCLN、ASCLC、ASDNC、ASDJC、ASTUP、ASVJB、ASVJC、ASVJP、ASVKB、ASVKC、ATJNR、AWLNR

【Boring Bar with coolant】

L-SCLC-V、L-SDUC-V、L-STLC-V、L-STUP-V

【Threading Tools with coolant】

ASER、ASER-WP、ASER-NA

【Grooving holder with coolant】

ACGWS、AEVSC/M、ADGT、AGHR、AGNDMR、AGHSR、AGWC、AKGD、ASLAL-38、ATGTR、ATSE、ATTE、AWGCSM、AUASR、AUSR

MONGTEC PRECISION INC.

Product Description :

◎ The general spindle speed is only 6000-15000rpm, and the tool can be pushed up to 55000rpm through 15-70bar coolant pressure, saving 70% of cycle time

◎ Various interfaces can choose BT/HSK/ER/PCS/straight

◎ Tool can be changed by ATC

◎ Display processing tool speed with chip transmission

◎ Excellent run out within 0.003mm

SHARPMAX TOOL INC.

Product Description :

● Periodic cutting stree is effectively suppressed by

continuously changing outer teeth spacing,allowing

for chattering control.

● Excellent anti-vibration performance compatible in a

wide variety of milling for exotic alloys including

SUS,inconel,and Titanium.

● Reduces chattering for high-speed and high-feed

cutting.

● Ultra-smooth coating with significantly

improvedcoating hardness and heat resistance

improves tool live in heat resisitive ally maching.

GUEY CHERNG TRADING CO., LTD.

Product Description :

SIMPLE

Tool is clamped in 8 seconds by pushing

only one single button.

SAFE

No heat up – high clamping force. Excellent vibration dampening.

HIGH PRECISION

Toolholder runout TIR ≤ 1 μm

Total system runout TIR ≤3 µm at 3 x D.

powRgrip®

The tool clamping system of today and the future.

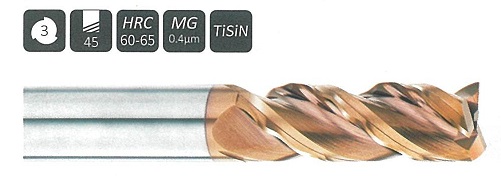

SHARPMAX TOOL INC.

Product Description :

● Designed for high performance rough machining of

Titanium and other exotic materials.

● Optimum performance with maximum chip load per

tooth and efficient chip formation with higher

volume of metal removal.

● Exclusive PVD coating for long life.

● Vibration Free.

HAINBUCH GmbH

Product Description :

Ideal for today's high paced manufacturing environment!

Convenient, that the HAINBUCH quick change-over systems fit on all your machines. Even better, that you can change your clamping devices in a matter of minutes, thus earning money quicker and allowing you to manufacture job-oriented. And, thanks to our unique technology, you will achieve a repeatability of ≤ 0.003 mm on the interface.

However, our high-speed solutions have even more to offer: As you will experience shorter machine downtimes along with reduced processing and throughput times,

your quick change-over systems will pay off in no time. Better yet, you will not have to compromise on quality, rigidity or precision.

Select the spindle connection and the clamping device that is right for you from our extensive assortment. We can even accommodate you if you are already using clamping devices made by other manufacturers. We will simply adapt them to our interface.

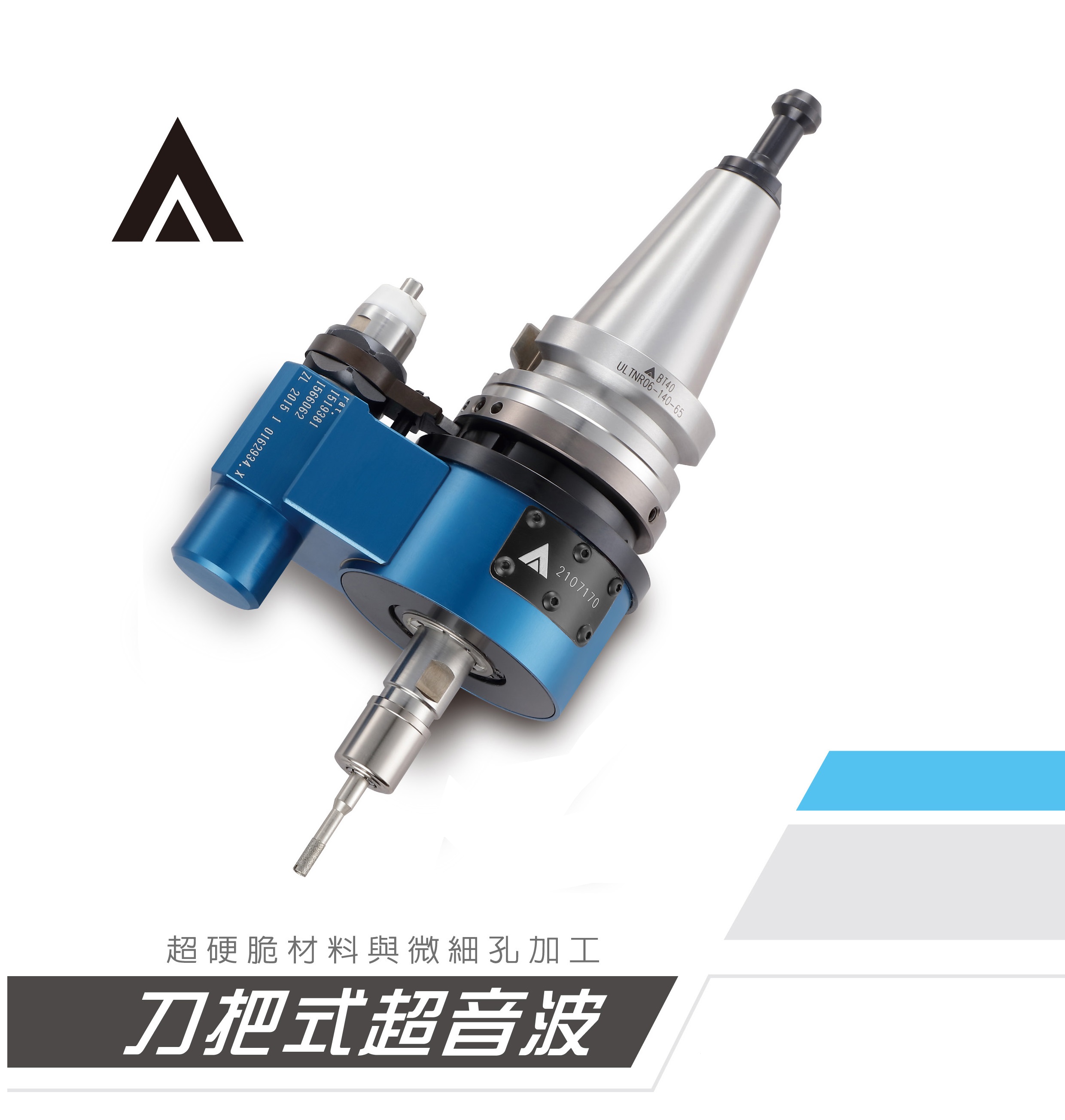

ACROW MACHINERY MFG. CO., LTD.

Product Description :

For Hard brittle material and micro holing drilling / Toolholder support for coolant function /

Clamping accuracy under 5 micro with the spring collets/ No need for special machine /

Easy to operate and install /

Reducing cutting resistance /

Improve surface roughness