Theme

Digital Transformation

Green Transformation

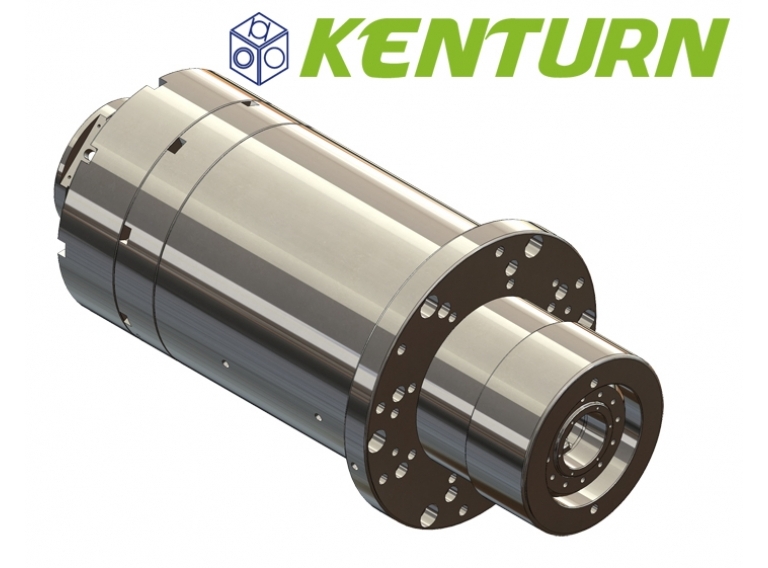

KENTURN NANO. TEC. CO., LTD.

Product Description :

Our own manufacturing spindle can fulfill the coolant of axis also inhibit the heat and thermal deformation by using the Germany original OTT HSK-A63 drawbar system. Besides, the oil-air lubricating bearings can stand long-term cutting operation. The spindle, motor power is up to 25KW, speed 18000 RPM, using dualdrive chunk, can be used in vertical machining centers and medium gantry machine.

MAROX TOOLS INDUSTRIAL CO., LTD.

Product Description :

【External Turning Tools with coolant】

AACLN、AATJN、AATQN、AAWLN、ADCLN、ADDJN、ADDQN、ADTEN、ADTJN、ADTQN、ADVJN、ADWLN、AMCLN、AMDJN、AMTJN、AMVJN、APCLN、ASCLC、ASDNC、ASDJC、ASTUP、ASVJB、ASVJC、ASVJP、ASVKB、ASVKC、ATJNR、AWLNR

【Boring Bar with coolant】

L-SCLC-V、L-SDUC-V、L-STLC-V、L-STUP-V

【Threading Tools with coolant】

ASER、ASER-WP、ASER-NA

【Grooving holder with coolant】

ACGWS、AEVSC/M、ADGT、AGHR、AGNDMR、AGHSR、AGWC、AKGD、ASLAL-38、ATGTR、ATSE、ATTE、AWGCSM、AUASR、AUSR

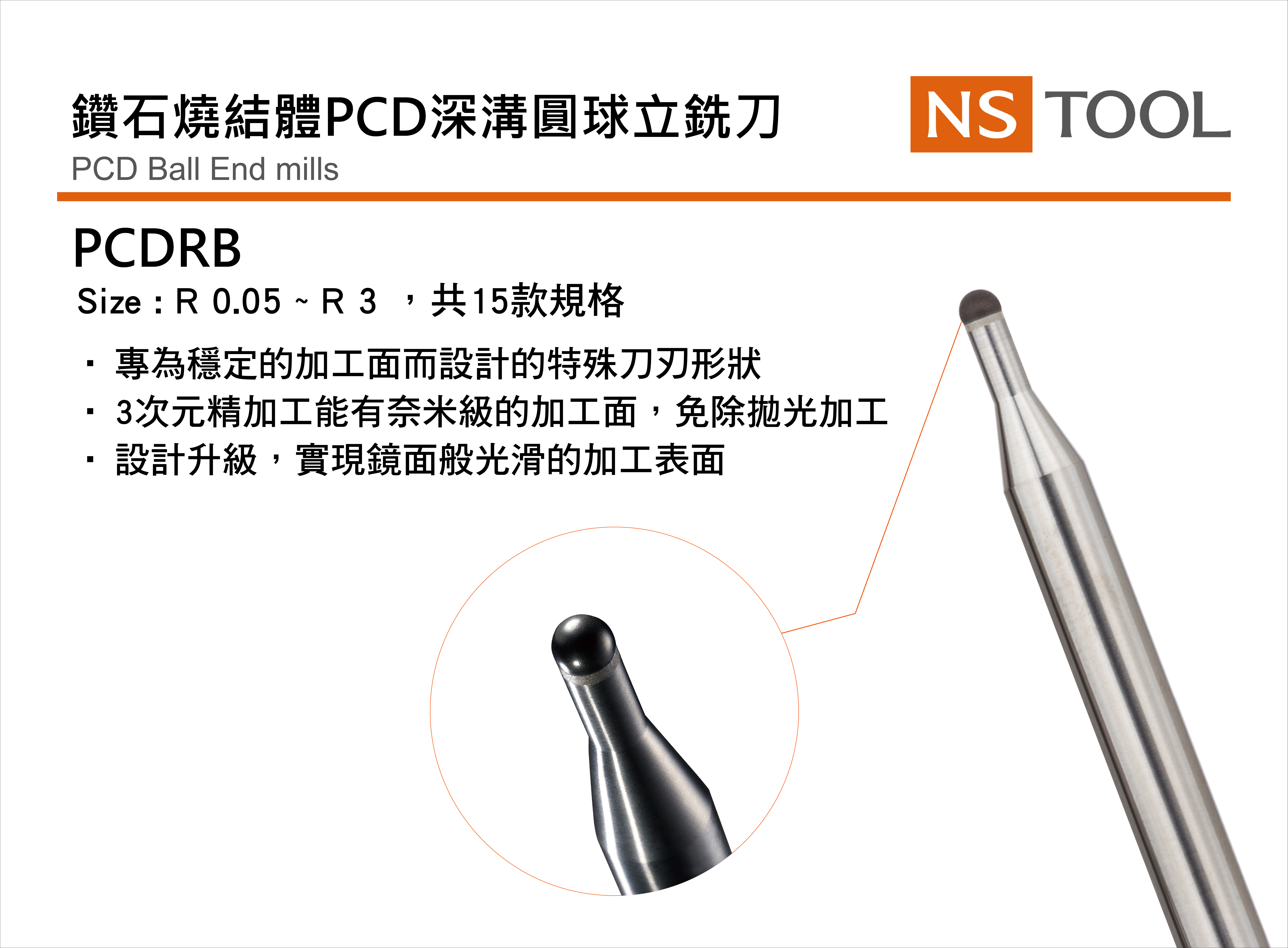

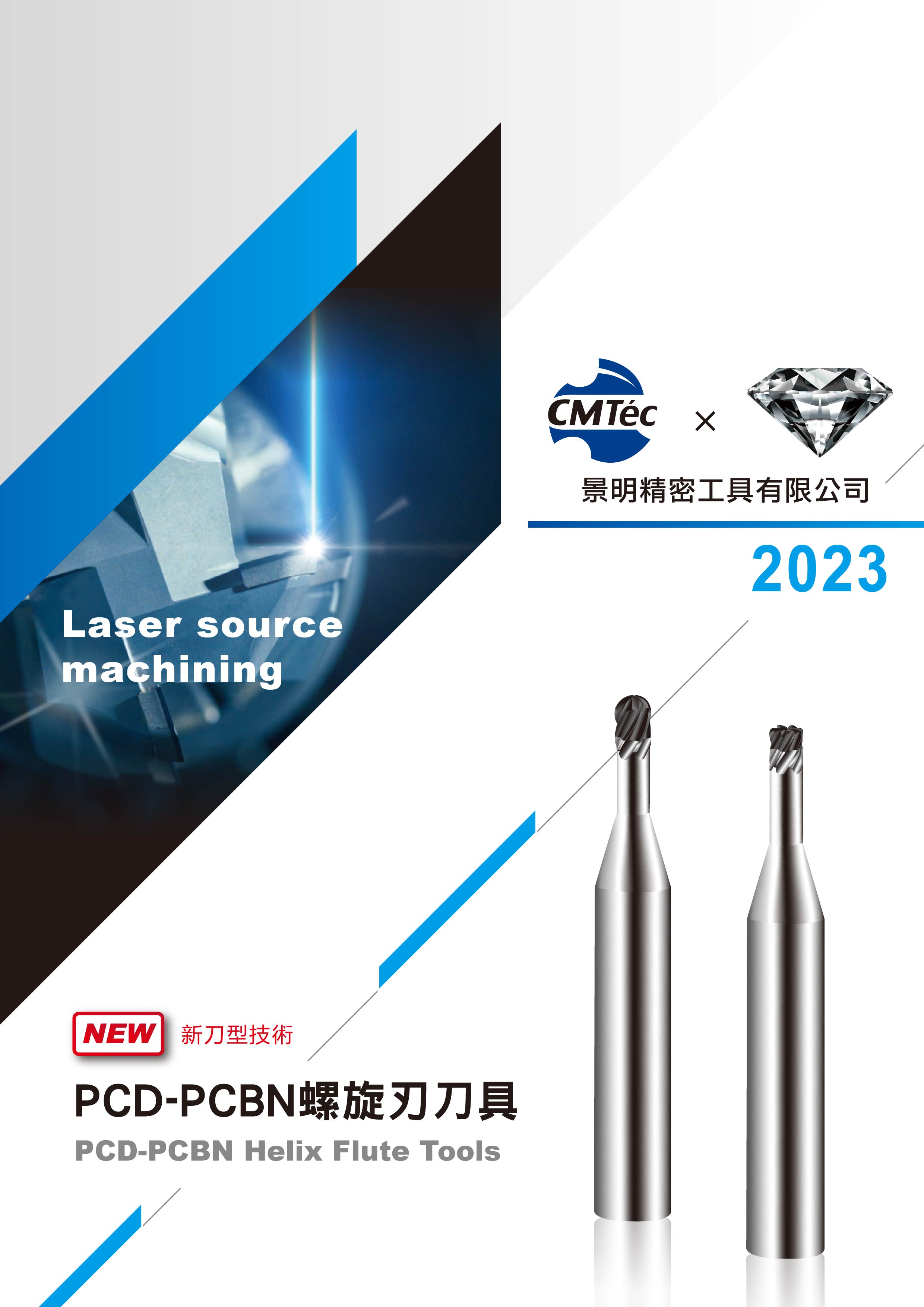

CHIN MING PRECISION TOOLS CO., LTD.

Product Description :

For Ultra-Hard Material Machining

(For Carbide, SiC, Al2O3, Si3N4 and ZrO2 Machining.)

------------------------------------------------------------

PCD Helix Flute End Mills- Multi-Flute:

★ Multi-flute decreases cutting resistance and makes high efficiency.

★ Applies to high precision machining of carbide and ceramics.

PCD Helix Flute Drilling:

★ For carbide, ceramics, aluminum, copper, graphite and carbon fiber drilling.

PCD Ball Rolling Cutter:

★ Special cutting edge and high accuracy R of ±0.005mm realize high quality mirror polished machining.

★ Applies to carbide and hardened steel(≦70HRC) mirror polished machining.

PCBN Helix Flute End Mills:

★ For hardened steel(HRC45~65°) and powder metallurgy machining.

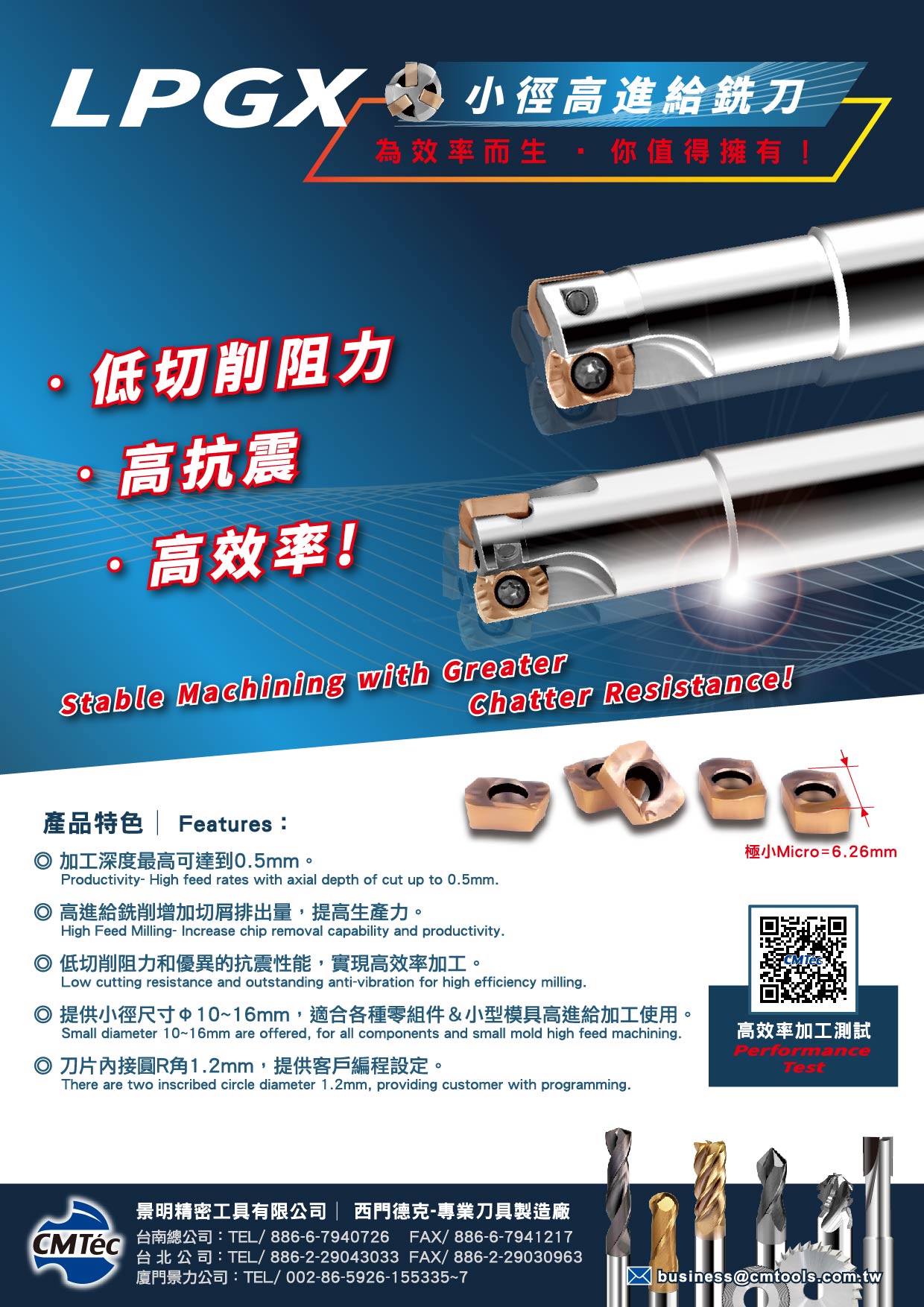

CHIN MING PRECISION TOOLS CO., LTD.

Product Description :

★ Productivity- High feed rates with axial depth of cut up to 0.5mm.

★ High Feed Milling- Increase chip removal capability and productivity.

★ Low cutting resistance and outstanding anti-vibration for high efficiency milling.

★ diameter 10~16mm are offered, for all components and small mold high feed machining.

★ There are two inscribed circle diameter 1.2mm, providing customer with programming.

HON JAN CUTTING TOOLS CO., LTD.

Product Description :

●Internal and external threading for both left-thread and right-thread with one tooling

●Safe machining operation and easier to reach the bottom inside the blind holes

●Evacuate the chip more efficiently than the traditional milling process. shank: 20mm~40mm , Internal Thread Insert: 12I , 14I, 21I, 30I , 40I , External Thread Insert: 14E, 21E, 30E , 40E

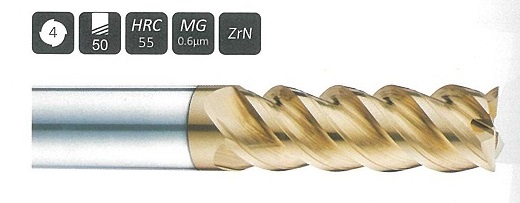

SHARPMAX TOOL INC.

Product Description :

● Engineered with eccentric relief for maximum edge strength in both roughing and finishing applications.

● Variable pitch geometry results in higher quality parts by decreasing chatter and harmonics.

● ZrN coating offers high hardness for estended tool life in high temp alloys and ferrous metals including stainless stee.

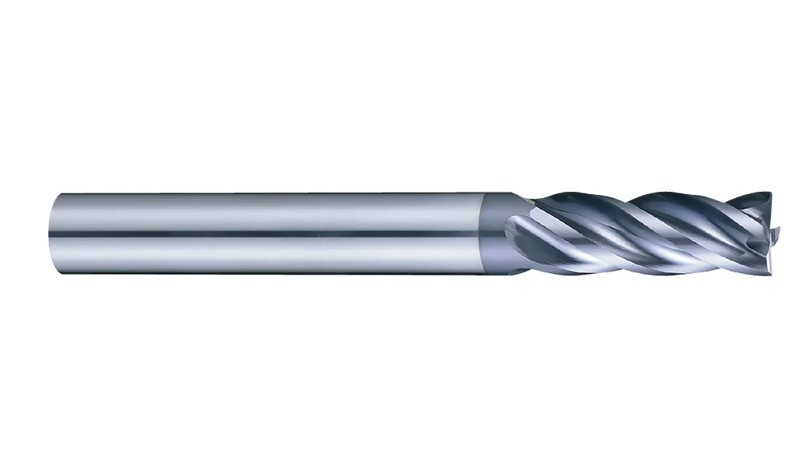

7-LEADERS CORP.

Product Description :

Multipurpose End Mills- 4 Flutes

Effectively decrease the vibration by various helix geometry and unequal flutes designs.

Big chip breaker is designed to reach high removal rate for various work materials.

Obviously improve tool life with Nano multilayer coating AlTiCrN.

Suitable for different kinds of materials cutting.