Theme

Digital Transformation

Green Transformation

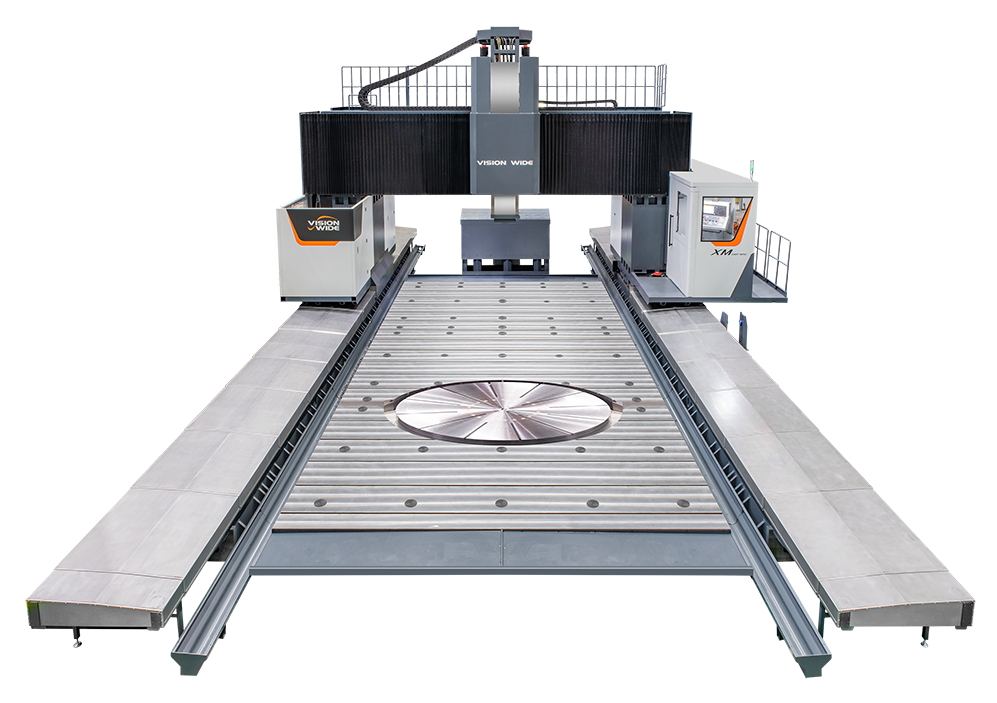

VISION WIDE TECH CO., LTD.

Product Description :

High Performance and Wide Application

XM series moving column machining center is a product developed for the machining needs of large-scale precision machinery, electric power, wind power, energy, petrochemical, transportation... and other equipment. It has:

Huge workpiece machining space: For precision machining of various types of structural parts, it can provide super large XYZ axis machining space.

• High-precise positioning: The high-standard geometric accuracy and positioning accuracy capabilities of the whole machine enable large-scale precision machining

• Heavy cutting capacity: Provide a variety of high-rated torque spindles to meet the processing and cutting capabilities of various materials.

• Fully automatic multi-face machining: This moving column machining center can be matched with various automatic attachment heads for high tangential speed mold surface machining and various types of precision parts complex angle machining, with excellent tool tip point error automatic correction function, and automatic additional head and tool exchange function, it can realize fully automatic machining performance.

• Milling and turning compound multitask: This moving column cnc milling machine can be equipped with a high-torque and high-speed vertical turning table to realize milling and turning compound automatic machining.

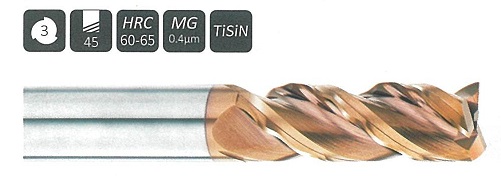

SHARPMAX TOOL INC.

Product Description :

● Designed for high performance rough machining of

Titanium and other exotic materials.

● Optimum performance with maximum chip load per

tooth and efficient chip formation with higher

volume of metal removal.

● Exclusive PVD coating for long life.

● Vibration Free.

HON JAN CUTTING TOOLS CO., LTD.

Product Description :

Heat-treated steel

Coolant design

Perfect 90° milling

High number of teeth, increased productivity

PTN10-cutting depth up to 5mm

PTN16-cutting depth up to 10mm

PTN16-the clamping screw is enlarged for easier locking and greatly improved stability

The unique design of low cutting resistance can better machining continuity, achieve milling of 90°, and get a perfect machining surface.

NINE-9 CUTTING TOOLS CO., LTD.

Product Description :

This is a revolutionary new concept of engraving tools with indexable carbide inserts. They offer you the ability to produce HIGH QUALITY ENGRAVING in most materials.

The latest coated carbide grades help you to obtain higher speed and feed rate, dramatically reducing your cycle time.

● High Positive Rake Angle

• Indexable insert.

• Suitable for engraving all types of materials, such as plastic, non-ferrous metal, aluminum, copper, carbon steel and stainless steel.

● Multi-Side Grinding

• Full peripherally ground insert to ensure efficient repeatability.

• It performs excellently without producing any burrs, especially in copper, aluminum and stainless steel.

● High Speed, High Feed Rate

• Designed to run at high speed, up to 40,000 r.p.m.

• Feed rate 0.08mm (0.003”) / rev. apply to aluminum; 0.05mm (0.002”) / rev. apply to stainless steel.

• Reduces engraving cycle time!

● Economical

• Each indexable insert has 2 cutting edges.

• No resharpening required. Tool length is unchanged.

• No need to reset after changing insert or cutting edge.

• Excellent repeatability!

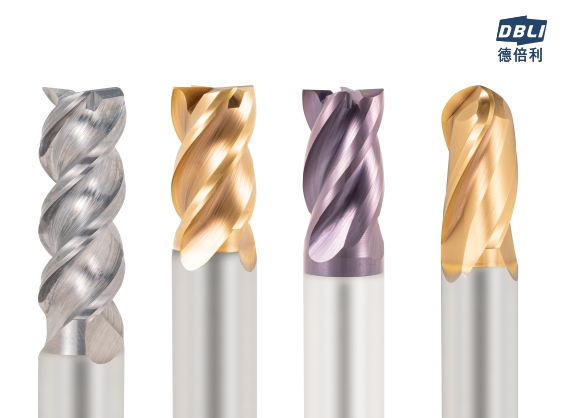

DEEP JET INDUSTRY CO., LTD.

Product Description :

1. Use in high speed machining and hard workpiece machining. It improves the quality and machining speed which is the best choice for precision processing.

◆Carbide Asymmetric Corner Radius End Mill (Steel)-Asymmetric helix angle 40º/42º and unequal flute design to effectively reduce the vibration rate and increase the tool's stability.

◆Carbide Asymmetric End Mill (Aluminum)- Reinforced asymmetric 50/50.5/51 and unequal flute design to effectively reduce the vibration rate and increase the tool's stability. This makes the surface smoother.

◆Carbide Asymmetric End Mill (Steel)-Reinforced asymmetric 36º/38 º design with special grinding technique to reach better surface roughness. Avoid vibration problem during machining and increase tool's stability.

◆Carbide Asymmetric End Mill (Aluminum)- Reinforced asymmetric 44.5º/45º/45.5º design with special grinding technique to reach better surface roughness. Avoid vibration problem during machining and increase tool's stability.

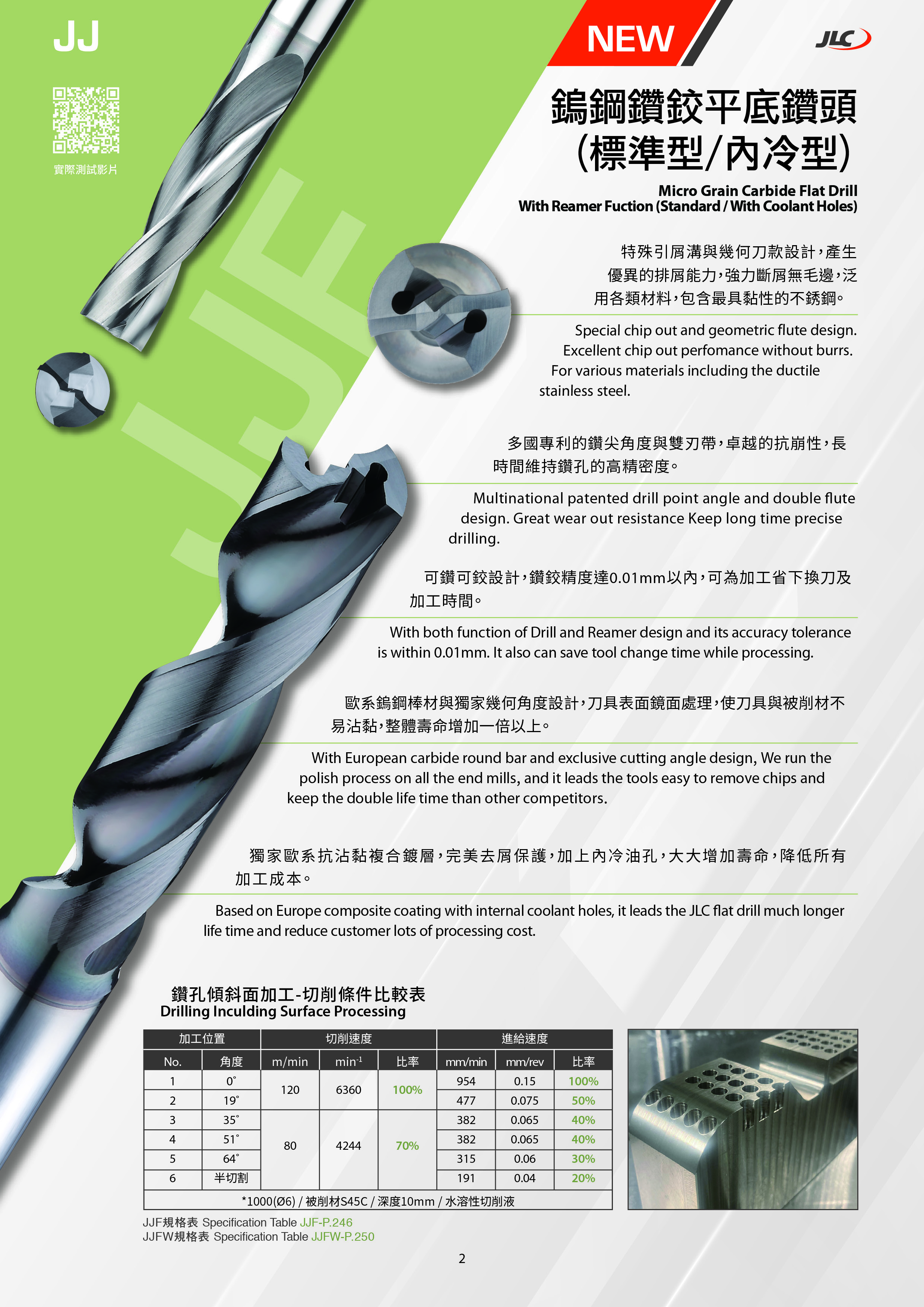

JIN LI CHENG CUTTING TOOL CO., LTD.

Product Description :

※Special chip out and geometric flute design. Excellent chip out perfomance without burrs. For various materials including the ductile stainless steel.

※Multinational patented drill point angle and double ute design. Great wear out resistance Keep long time precise drilling.

※With both function of Drill and Reamer design and its accuracy tolerance is within 0.01mm. It also can save tool change time while processing.

※With European carbide round bar and exclusive cutting angle design, We run the polish process on all the end mills, and it leads the tools easy to remove chips and keep the double life time than other competitors.

※Based on Europe composite coating with internal coolant holes, it leads the JLC at drill much longer life time and reduce customer lots of processing cost.

VISION WIDE TECH CO., LTD.

Product Description :

One of the proudest products of Vision Wide which fulfills automatic 5-face machining with super rigidity structure and high positioning accuracy. HF satisfies demands in mold surface cutting, angle cutting, 3D mold cutting, and precise contour finishing.