Theme

Digital Transformation

Green Transformation

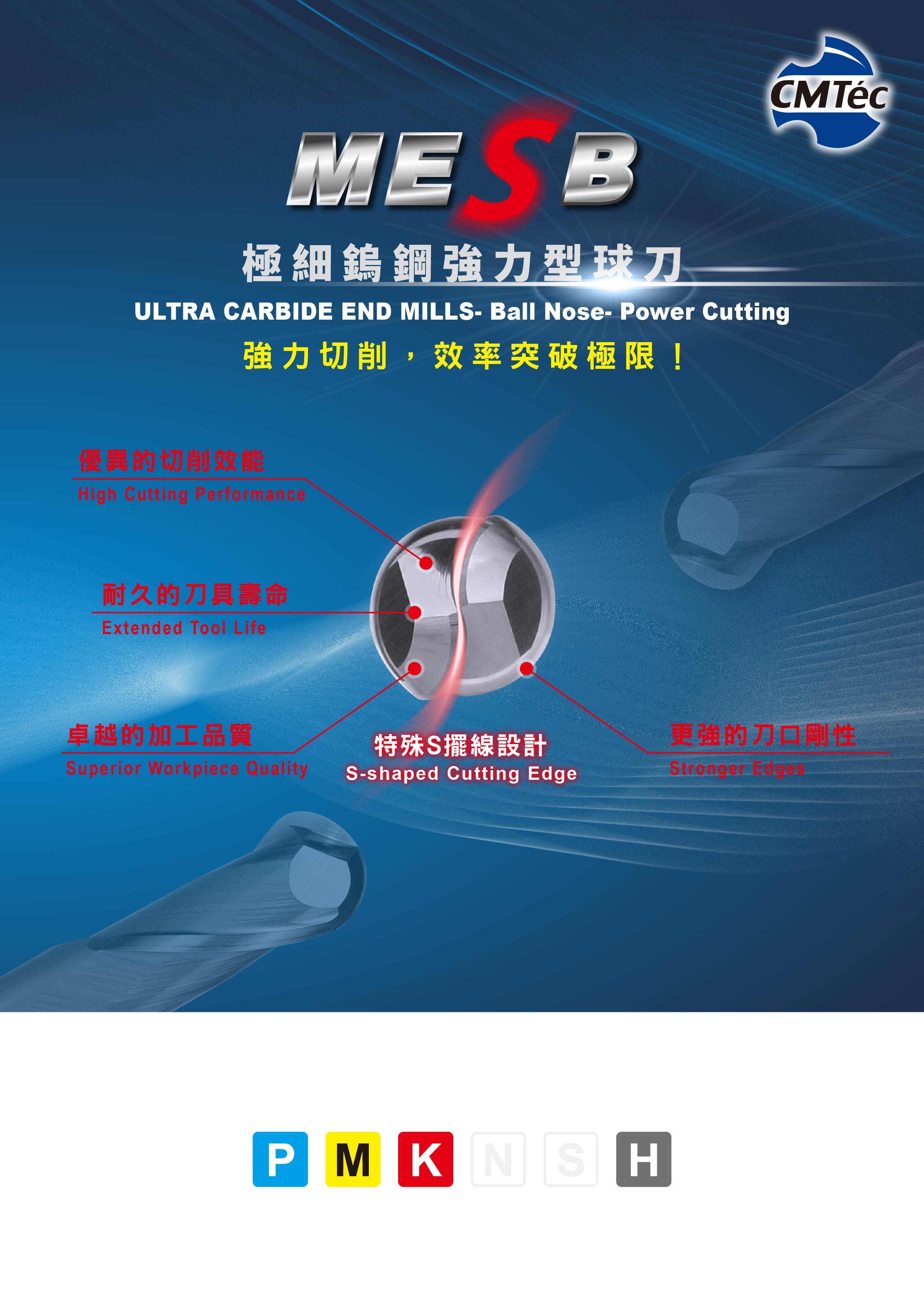

CHIN MING PRECISION TOOLS CO., LTD.

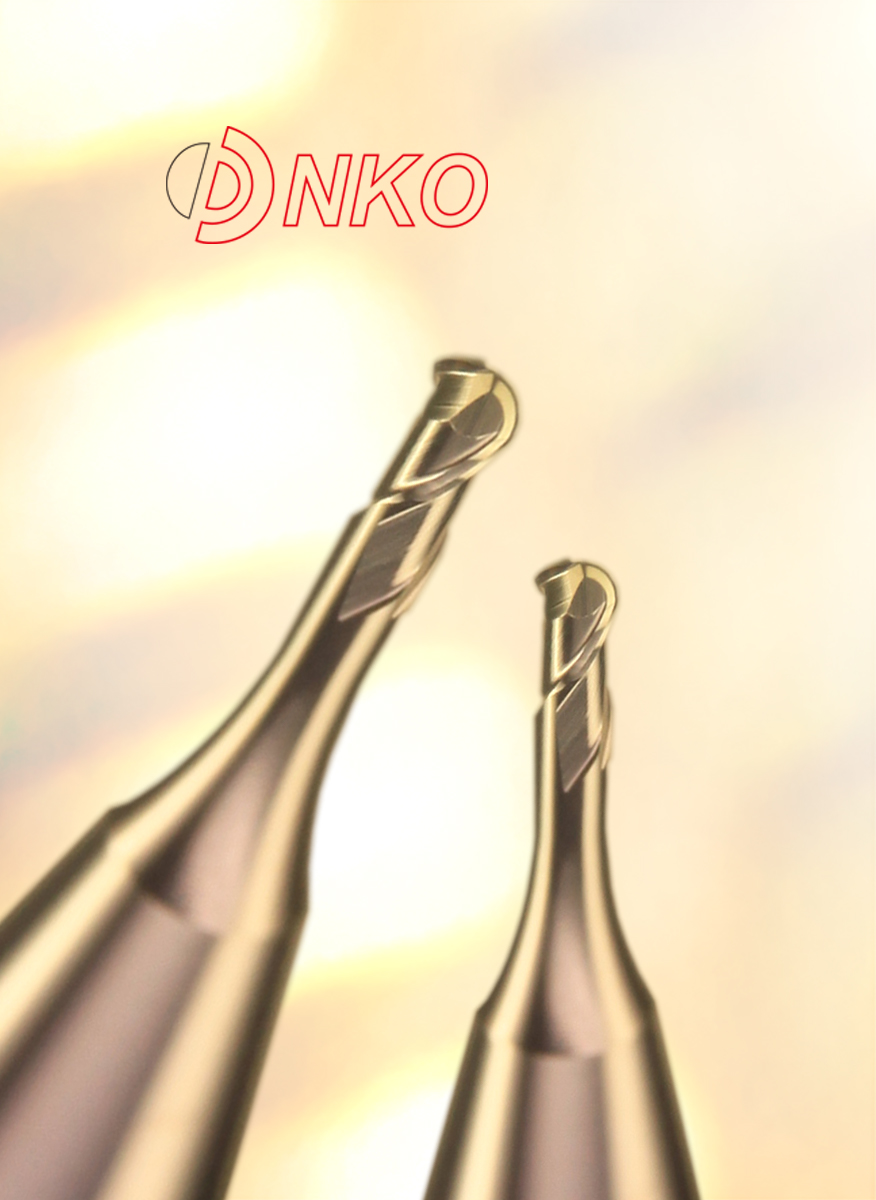

Product Description :

★ Cutting edges and workpiece reduce contact area, lower cutting resistance and boost efficiency.

★ Cutting edges distribute cutting forces evenly, reducing wear and extending tool life.

★ Minimizes vibration during machining, improving surface finish and precision.

★ For copy milling alloy steel, hardened steel (≦60°HRC), stainless steel and cast iron.

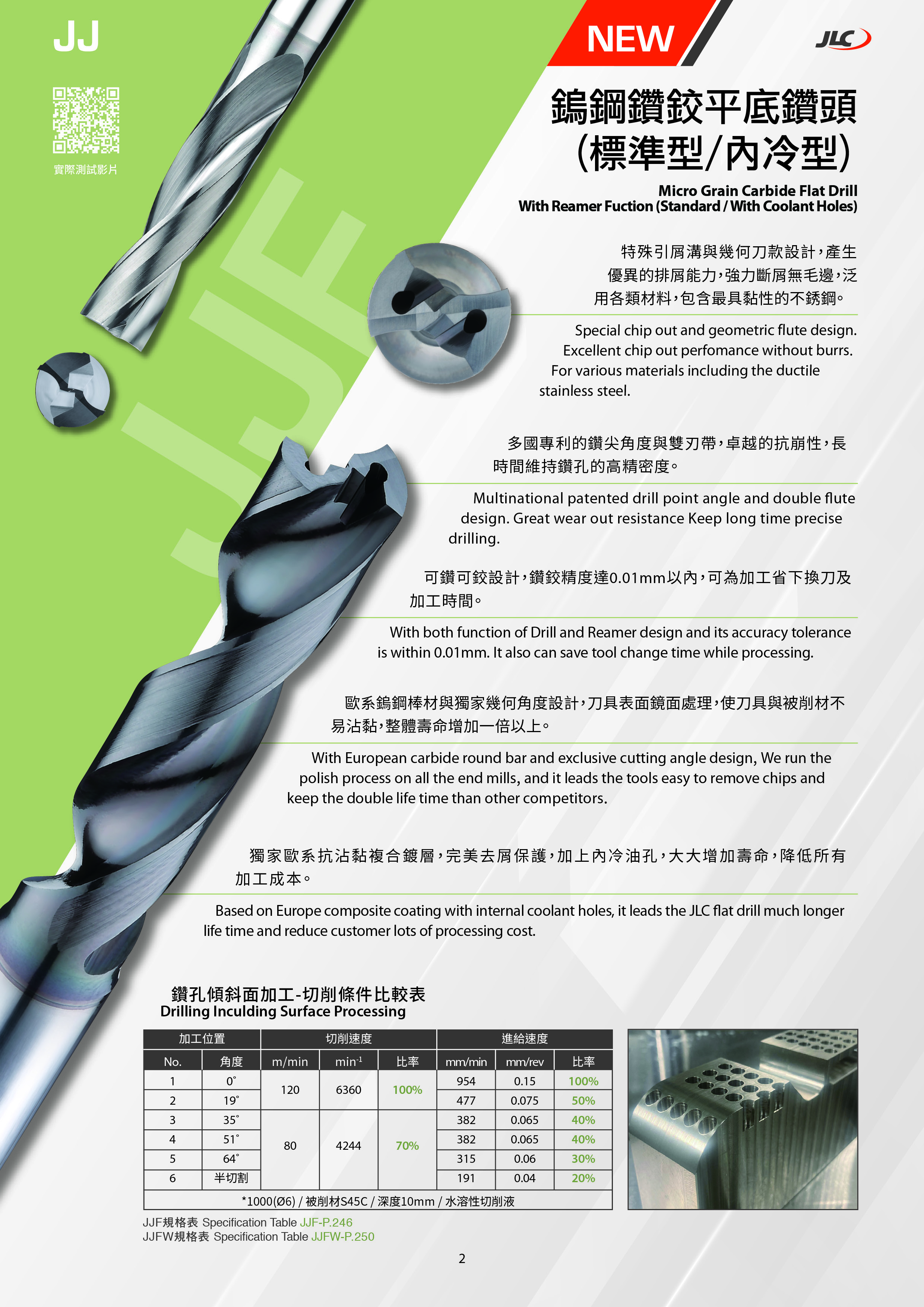

JIN LI CHENG CUTTING TOOL CO., LTD.

Product Description :

※Special chip out and geometric flute design. Excellent chip out perfomance without burrs. For various materials including the ductile stainless steel.

※Multinational patented drill point angle and double ute design. Great wear out resistance Keep long time precise drilling.

※With both function of Drill and Reamer design and its accuracy tolerance is within 0.01mm. It also can save tool change time while processing.

※With European carbide round bar and exclusive cutting angle design, We run the polish process on all the end mills, and it leads the tools easy to remove chips and keep the double life time than other competitors.

※Based on Europe composite coating with internal coolant holes, it leads the JLC at drill much longer life time and reduce customer lots of processing cost.

CHIN MING PRECISION TOOLS CO., LTD.

Product Description :

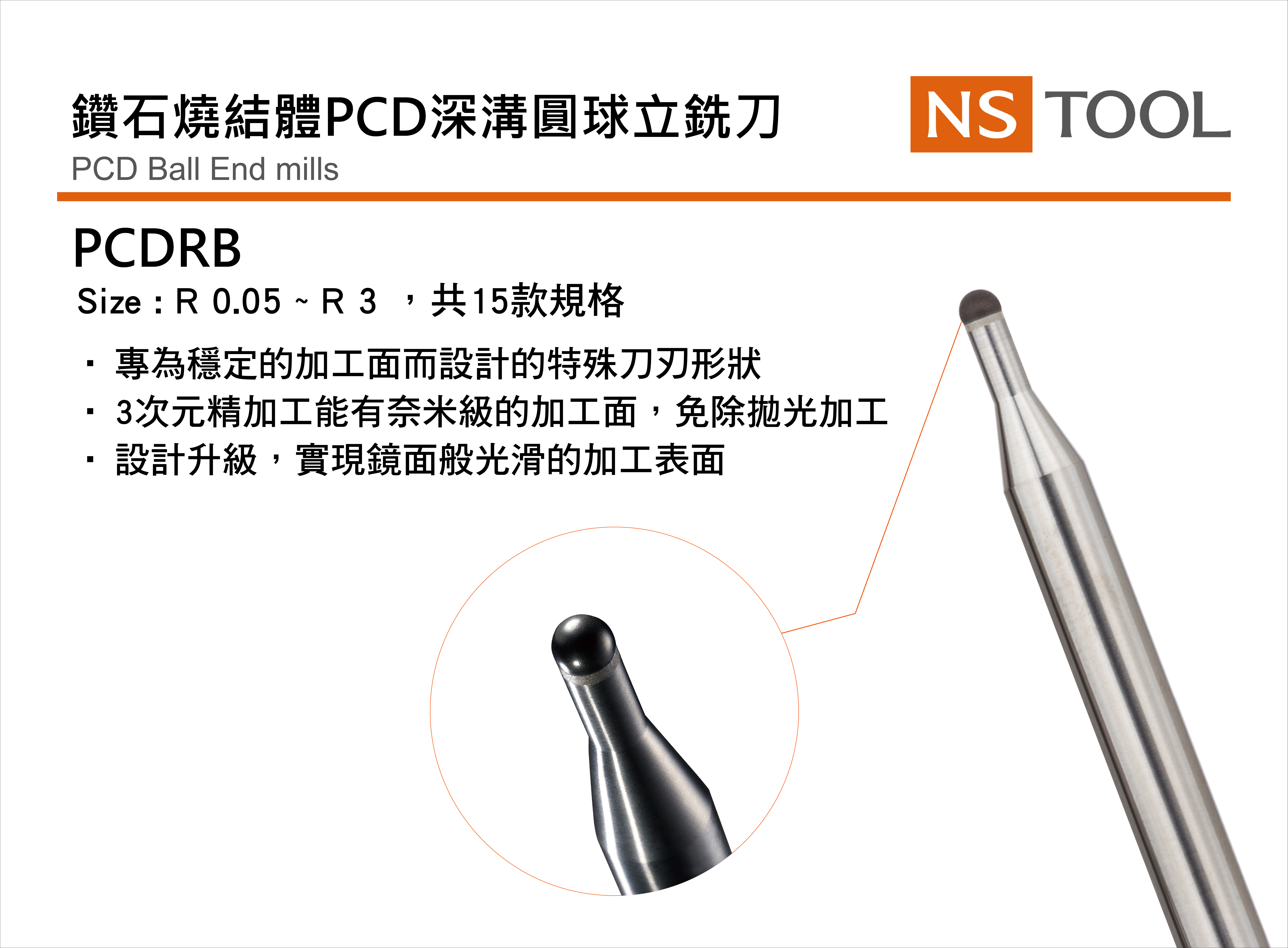

PCD DIAMOND CUTTING TOOLS:

★ For high-efficiency machining of silicon carbide(SiC), aluminum oxide(Al2O3), zirconium oxide(ZrO2), quartz(SiO2), Silicon(Si) and carbide.

★ Multi-flute design of end mills reduces cutting resistance and enhances machining efficiency.

★ PCD helix tools can effectively shorten machining time, ensure stable machining accuracy and significantly improve production efficiency.

NINE-9 CUTTING TOOLS CO., LTD.

Product Description :

NC Helix Drill cuts material by helical interpolation; serrated cutting edge minimizes chip length.

Low spindle power is not a problem, good for drilling material that generates long, soft chips.

● Reduce Your Tool Inventory

Each holder can machine di erent diameters and hole depths, saving your tool inventory and cost!

No need to peck drill or dwell in operation even machine without internal coolant.

● Lower spindle power consumption Easy to cut!

• Thanks to the small cutting load of the serrated cutting edge and helical interpolation lower power consumption. Work quicker, smarter and achieve better results.

• Circular ramping milling, maximum ramping angle is 20°. For example: tool HD27 machining Ø50 mm hole, 9 mm pitch for aluminum, 6 mm pitch for carbon steel.

● Special insert geometry - exceptional swarfs control.

• Serrated cutting edge makes the chips short and small, and easier to evacuate.

• Eliminate swarf and vibration problems while drilling di cult material or deeper holes.

● “One tool” performs multiple applications

• Not only a drill, but an end mill too.

• Small radius path to cut a hole or step hole, various curved cavity shapes on di erent materials.

Fey Che Trading Co., LTD.

Product Description :

MUGEN COATING PREMIUM Plus具有高抗氧化性和耐磨性,適用於 60HCR 以上的加工。即使在 45~60HRC的加工中也能表現出與 MUGEN COATING PREMIUM 相同的性能。____________________________________________________________

[ 方 頭 銑 刀 ]

[ 型號 : MHDSH445・MHDSH645 ]

*刃長有2D與3D型式可供選擇

*採用最新開發之白金級PLUS無限鍍膜,最適合加工45~70HRC之高硬度鋼材

*高剛性設計實現高精度加工____________________________________________________________

[ 球 頭 立 銑 刀 ]

[ 型號 : MSBSH330-5X ]

*採用耐崩損性佳的新素材及銳角刃口設計,可以減輕切削抵抗

*採用不等分割設計,可以防止震刀

*5軸機專用圓球立銑刀

[ 型號 : MRBSH330 ]

*最優化中心刃形狀、 能進行高切削深的高效率

*加工即使在45〜70HRC高硬度鋼,兼具切削性與

*耐磨耗性,能實現長壽命、高效率的加工

[ 型號 : MRBSH230SF ]

*加工70HRC的高硬度鋼材,也能實現長壽命及穩定的加工性能

*採用耐崩損的新素材及減低切削抵抗的刃口設計____________________________________________________________

[ 端 角 R 立 銑 刀 ]

[ 型號 : MHRSH430RSF ]

*全新的修光刃設計可提升平面加工表面品質

*R角無段差設計,提升側面加工表面品質

*高剛性設計實現高精度加工

JIN LI CHENG CUTTING TOOL CO., LTD.

Product Description :

※ We design and manufacture "speci c industry" tools

with fast delivery and great quality.

※ It can be designed according to the highest standard

and speci cation from customers. Flexible manufacturing

and accept customized tolerance.

※ From concept to nal completion. JLC customized

tools will reduce the cutter exchange labor time and

improve the e

ciency of mass production.

NINE-9 CUTTING TOOLS CO., LTD.

Product Description :

Nine9 chamfer mill is designed for chamfering and countersinking with an indexable insert.

The insert is a specifically designed for use in high speed machining ; the multiple flutes

provide for increased feed rate, optimizing performance and reducing cutting time.

High performance chamfer tool for upgrading your machining process.

For front and back chamfering. Eliminates 2nd operation or deburring time.

● Excellent Repeatability

• Smallest Indexable counter sink, diameter ø7 mm.

• The insert is dual-relief angle, specially edge honning and optimized coated for high cutting speed.

• Optimized the number of teeth on the holder to achieve higher feed rate.

● Economical

• Each insert has 4 cutting edges.

• Long tool life.

● Applications

• For front and back chamfering.

• 90° counter sink and 45° chamfering.

• For counter sink, circular chamfering, contour chamfering and face milling.

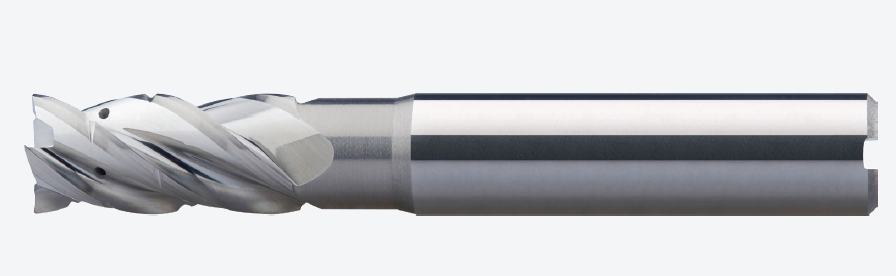

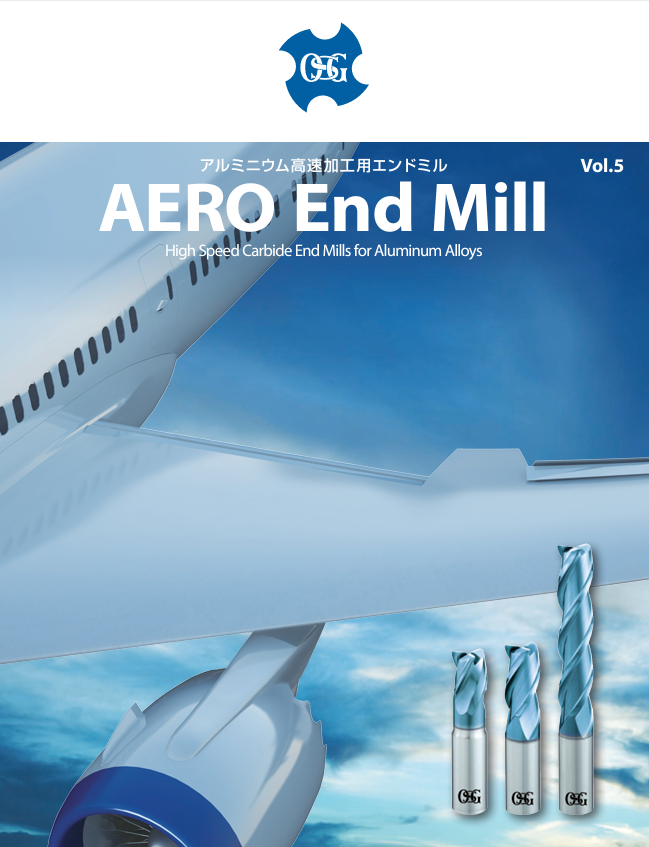

TAIHO TOOL MFG. CO., LTD.

Product Description :

The AERO series is very suitable for high-power equipment above 80KW.

It has a sharp cutting edges and grooves for great efficiency of discharging the chips. The coating is OSG's diamond coating with glossy surface. This bright and smooth surface optimizes the performance of the end mill, especially in aluminum alloy that weldability and lubricity are required.

The 3-short-blade type and center jet type (AERO-ETS, AERO-O-ETS) are corner radius end mills applied to roughing and finishing.

The 3-long-blade type and extra long blade type (AERO-ETL, AERO-EXTL) are corner radius end mills applied to roughing and finishing.

The 2-short-blade type (DLC-AIR-EDS) is corner radius end mills applied to roughing and finishing.