Theme

Digital Transformation

Green Transformation

MONGTEC PRECISION INC.

Product Description :

BODY

Re-designed main body to improve rigidity and reduce vibration. Specially treated corrosion resistant steel body.

Bearings

Angular contact preloaded ball bearings of precision class P4 / ABEC 9.

Bevel Gears

Gleason computer based calculations for the Gleason cut spiral bevel drive gears with ground teeth in order to guarantee a bigger torque.

Torque and Speed

With Speeder 1:4:32,000 Rpm

(Standard 1:1:6000~12000Rpm)

Max Torque:160Nm

Internal Coolant

Max Pressure:70-100 bar

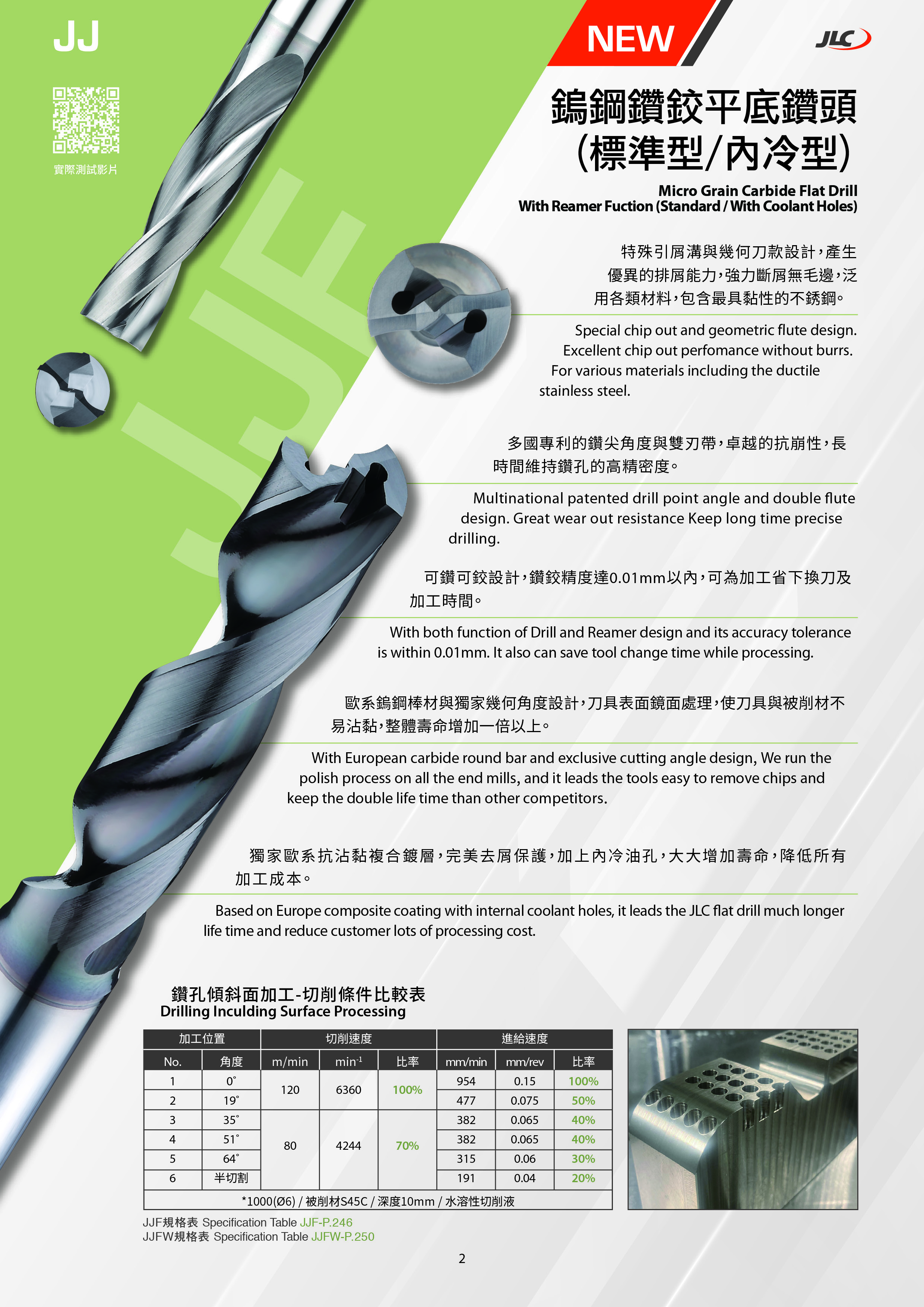

JIN LI CHENG CUTTING TOOL CO., LTD.

Product Description :

※Special chip out and geometric flute design. Excellent chip out perfomance without burrs. For various materials including the ductile stainless steel.

※Multinational patented drill point angle and double ute design. Great wear out resistance Keep long time precise drilling.

※With both function of Drill and Reamer design and its accuracy tolerance is within 0.01mm. It also can save tool change time while processing.

※With European carbide round bar and exclusive cutting angle design, We run the polish process on all the end mills, and it leads the tools easy to remove chips and keep the double life time than other competitors.

※Based on Europe composite coating with internal coolant holes, it leads the JLC at drill much longer life time and reduce customer lots of processing cost.

PRAISE PRECISION IND. CO., LTD.

Product Description :

NEW PRODUCT- CUTTING KNURLING TOOLS USED ON LATHE

Method of forming knurling

1. Press forming(Form knurling)

Press knurling tool directly to workpiece in turning on the lathe

to form the patterns. Pressure is applied to the lathe spindle, and the outside diameter of workpiece will become bigger

2. Cutting forming(Cut knurling)

The knurling tool is applied to workpiece just like cutting, less pressure

to lathe spindle and less machining resistance, forming a clear patterns, the best choice for using on CNC lathes

NINE-9 CUTTING TOOLS CO., LTD.

Product Description :

Nine9 chamfer mill is designed for chamfering and countersinking with an indexable insert.

The insert is a specifically designed for use in high speed machining ; the multiple flutes

provide for increased feed rate, optimizing performance and reducing cutting time.

High performance chamfer tool for upgrading your machining process.

For front and back chamfering. Eliminates 2nd operation or deburring time.

● Excellent Repeatability

• Smallest Indexable counter sink, diameter ø7 mm.

• The insert is dual-relief angle, specially edge honning and optimized coated for high cutting speed.

• Optimized the number of teeth on the holder to achieve higher feed rate.

● Economical

• Each insert has 4 cutting edges.

• Long tool life.

● Applications

• For front and back chamfering.

• 90° counter sink and 45° chamfering.

• For counter sink, circular chamfering, contour chamfering and face milling.