Theme

Digital Transformation

Green Transformation

CHIN MING PRECISION TOOLS CO., LTD.

Product Description :

★ Single Crystal Diamond(Ultra Precision Cutting):

【CVD- HV8,000 ~ 10,000】

【MCD- HV5,000 ~ 10,000】

Work Material:Ceramic, Gold / Silver / Aluminum / Copper / Zinc / Magnesium Alloy, Titanium Alloy, Graphite, Carbon Fiber / Glass Fiber, Wood, Bakelite, Acrylic, Stone, Electroless Nickel, Carbide.

★ Polycrystalline Compound Diamond【HV6,500 ~ 8,000】:

Work Material:Ceramic, Aluminum / Copper, Titanium Alloy, Graphite, Carbon Fiber / Glass Fiber, Wood, Bakelite, Acrylic, Stone, Carbide.

★ Polycrystalline Cubic Boron Nitride【HV3,000 ~ 5,000】:

Work Material:Hardened Steel(HRC45~65°), Powder Metallurgy.

BEST DIAMOND INDUSTRIAL CO., LTD.

Product Description :

Compared to resin bond and metal bond wheels, Electroplated Grinding Tools are noted for relatively large grit protrusion and higher abrasive concentration. This results in very free cutting properties and in high stock removal capacity. Besides, these tools are noted for:

1. Allow special shapes and profile tools to be made at short notice.

2. Cause very little change on wheel shape after used, suitable for precision grinding.

Application and Processing Material for Electroplated Grinding Tools :

1. Internal grinding: Suitable for the internal grinding of carbide and High Speed Steel. The smallest diameter of our electroplating area is 0.3mm so it could be used in drilling for fined ceramics.

2. Jig grinding: Mostly used in fined ceramics processing and precision grinding for quartz. Customized items are also provided to cater your needs. Common grit size is #80~#325, good for rough and fine processing.

3. Touchscreen Processing: Drilling and chamfering for the glass panel of the smart phone and tablet computer. In order to improve work efficiency, we could also combine different grit sizes in the same diamond mounted point.

4. Grinding for Cutting tools: Normal end-mill grinder and drill grinder go with electroplated wheel. Carbide can be ground by diamond wheel and High Speed Steel could be ground by CBN wheel. Bowl-shape wheel with standard specification is also provided, suitable for the grinding of turning tools.

5. Precision grinding: Electroplating can produce wheel of different shapes without deforming it. Therefore, it is suitable for precision grinding or trimming aluminum oxide wheel.

6. Gem grinding: shape grinding for gem, semi-precious stones, shell and jade.

VISION WIDE TECH CO., LTD.

Product Description :

One of the proudest products of Vision Wide which fulfills automatic 5-face machining with super rigidity structure and high positioning accuracy. HF satisfies demands in mold surface cutting, angle cutting, 3D mold cutting, and precise contour finishing.

YA LIANG INDUSTRIAL CO., LTD.

Product Description :

S-TYPE Special heavy duty model #122

Extremely high accuracy and precision design, suitable for CNC machining and machining center. All parts are ground, heat treated, surface treated and under specific QC condition.

H-TYPE Heavy duty model #123

Industrial design especially for milling machines and drilling machines.

All hardened parts ensure long life and safety while in operation.

DEEP JET INDUSTRY CO., LTD.

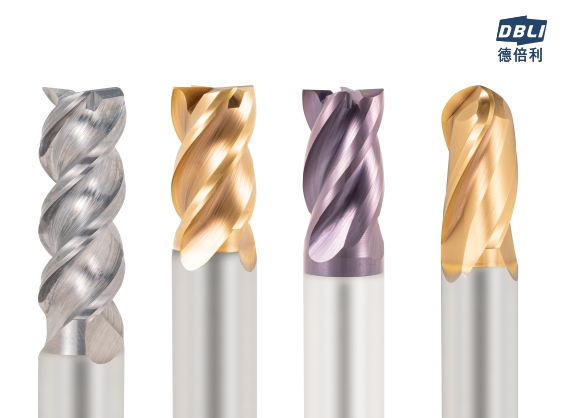

Product Description :

1. Use in high speed machining and hard workpiece machining. It improves the quality and machining speed which is the best choice for precision processing.

◆Carbide Asymmetric Corner Radius End Mill (Steel)-Asymmetric helix angle 40º/42º and unequal flute design to effectively reduce the vibration rate and increase the tool's stability.

◆Carbide Asymmetric End Mill (Aluminum)- Reinforced asymmetric 50/50.5/51 and unequal flute design to effectively reduce the vibration rate and increase the tool's stability. This makes the surface smoother.

◆Carbide Asymmetric End Mill (Steel)-Reinforced asymmetric 36º/38 º design with special grinding technique to reach better surface roughness. Avoid vibration problem during machining and increase tool's stability.

◆Carbide Asymmetric End Mill (Aluminum)- Reinforced asymmetric 44.5º/45º/45.5º design with special grinding technique to reach better surface roughness. Avoid vibration problem during machining and increase tool's stability.

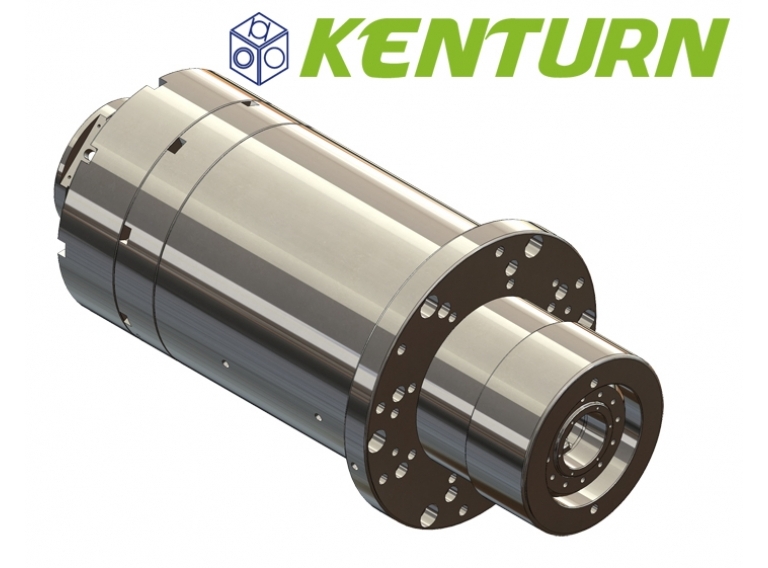

KENTURN NANO. TEC. CO., LTD.

Product Description :

Our own manufacturing spindle can fulfill the coolant of axis also inhibit the heat and thermal deformation by using the Germany original OTT HSK-A63 drawbar system. Besides, the oil-air lubricating bearings can stand long-term cutting operation. The spindle, motor power is up to 25KW, speed 18000 RPM, using dualdrive chunk, can be used in vertical machining centers and medium gantry machine.