Theme

Digital Transformation

Green Transformation

Hantop Intelligence Technology

Product Description :

Tool Holder Spec. provided:

BT30, BT40, HSKA63, HSKE25, HSKE32, HSKE40, CAT40

1. High Speed, high efficiency ultrasonic machining solution for high precision advanced materials machining(can reach 38000 rpm)

2. Plug and Play design for convenient and flexible Installation

3. Effective Intelligent Tracking System for advanced materials machining, finding the suitable resonance between tools and modules

4. Non-Contact transmission Design doesn't limit the high spindle rotation and reduce the impact from cutting heat, enhancing tool life and quality to next level.

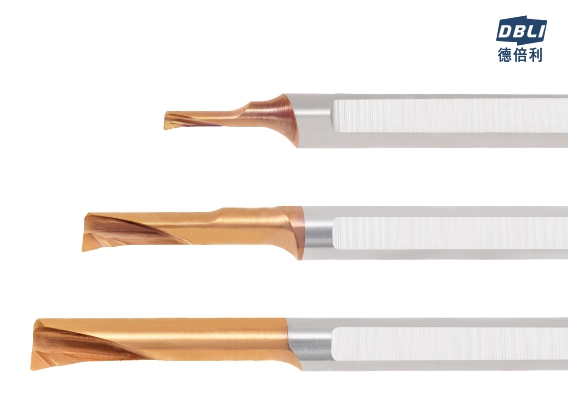

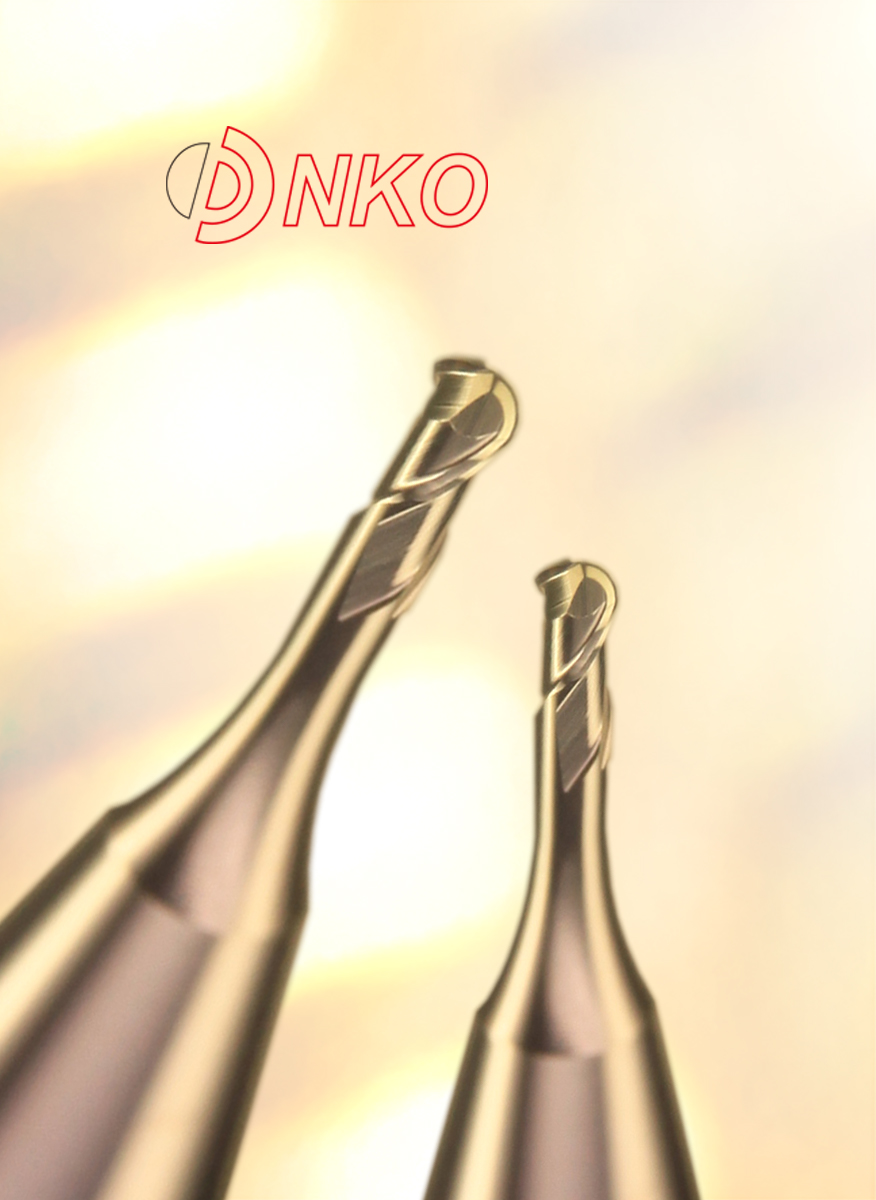

DEEP JET INDUSTRY CO., LTD.

Product Description :

1. With excellent features of coating to increase the tool's wear resistance and thermal conductivity to reduce the chip residue problem.

2. Use special flute design to decrease the chip-off problem during machining.

3. Increase machining accuracy and surface roughness.

TAIHO TOOL MFG. CO., LTD.

Product Description :

Carbide drill applying to EgiAs coating contains wide flute room facilitates stable chip evacuation, and M (Middle) Carbide drill applying to EgiAs coating contains wide flute room facilitates stable chip evacuation, and M (Middle) margin improves stability in deep-hole applications.

The series contain AD-2D/4D (without oil hole), ADO-3D/5D/8D (with oil hole), ADO-10D/15D/20D/30D/40D/50D (deep-hole application with oil hole)

Two point form based on the processing length:Wavy point form with oil hole makes long tool life become possible by breaking chip into small manageable pieces, lowing thrust resistance and stabling torque.

Straight point form with oil hole has both superior point strength and low cutting force.

HAINBUCH GmbH

Product Description :

Ideal for today's high paced manufacturing environment!

Convenient, that the HAINBUCH quick change-over systems fit on all your machines. Even better, that you can change your clamping devices in a matter of minutes, thus earning money quicker and allowing you to manufacture job-oriented. And, thanks to our unique technology, you will achieve a repeatability of ≤ 0.003 mm on the interface.

However, our high-speed solutions have even more to offer: As you will experience shorter machine downtimes along with reduced processing and throughput times,

your quick change-over systems will pay off in no time. Better yet, you will not have to compromise on quality, rigidity or precision.

Select the spindle connection and the clamping device that is right for you from our extensive assortment. We can even accommodate you if you are already using clamping devices made by other manufacturers. We will simply adapt them to our interface.

NINE-9 CUTTING TOOLS CO., LTD.

Product Description :

The “ i-Center ” is a trademark of Nine9,

the developer of the first indexable center drill in the world.(Patented)

Offering an indexable insert system for the 1st time, Nine9’s “i-Center ” design improves your process performance. Shortens set up and center drilling time.Increases tool life and reduces tooling costs.

● High Speed, High Feed Rate

• The special ground insert and rigid holder design facilitate high performance speed and feed rates. For example, drilling alloy steel

at 6000 rpm and feed rate of 600 mm/min. (0.1 mm/rev.).

● Excellent Repeatability

• The positioning repeatability of the insert is within 0.02 mm

(.0008”) in radial direction, thus ensuring conformity to any national

standards.

● Easy Tool Length Setting

• The axial position accuracy of the insert is 0.05 mm (.002”). It is

not necessary to reset the tool length when changing or cutting edge.

● Extended Tool Life

• Coolant can be supplied through the center of the holder to increase performance and extend tool life.

• Insert geometry, grades and coating process are specifically engineered for centering applications.