Theme

Digital Transformation

Green Transformation

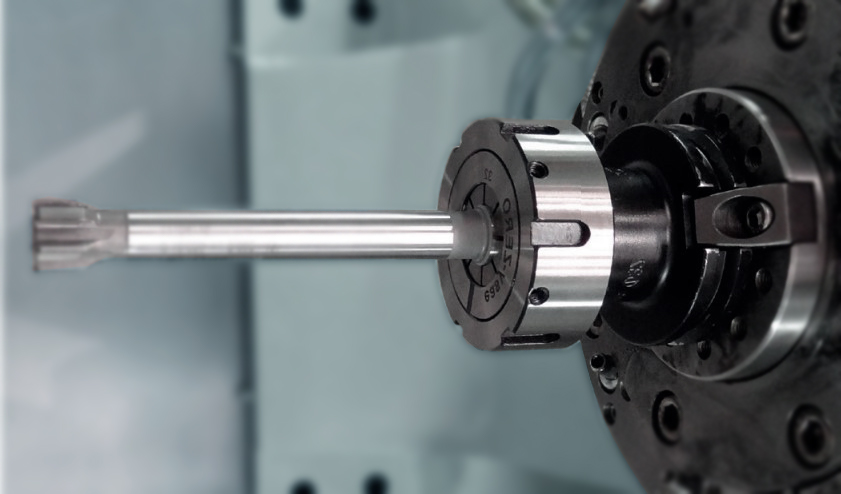

HAINBUCH GmbH

Product Description :

HAINBUCH segmented mandrels use state-of-the-art clamping technology that is convincing, even in the most critical applications. The central element is the vulcanized segmented clamping bushing. Because conventional clamping bushings are made of spring steel and are only annealed to spring hardness, they are »soft« and they must »bend« to clamp the workpiece. HAINBUCH segmented bushings are made of case-hardened chromium-nickel-steel and have segments that are extremely hard and rigid. All contact surfaces are completely ground in one operation guaranteeing optimum concentricity.

Mandrels with hexagonal clamping geometry, the MAXXOS mandrels. are the optimized version for round MANDO mandrels. Thanks to the hexagonal geometry, a previously unattained clamping force and rigidity with the best precision is now achieved for internal clamping. The robust and powerful clamping mandrel delivers first-class values in terms of dirt density. The force is transmitted by positive locking, in addition to optimum process reliability and long maintenance intervals.

MONGTEC PRECISION INC.

Product Description :

Product Features

◎ Correction of runout errors and misalignment

◎ For metallic sealed and normal collets as per DIN 6499 / ISO 15488

Product Advantages

◎ Easy to set

◎ Maximum process capability due to correction of runout

◎ Extended tool life due to perfect runout

◎ Highest quality of bores due to correction of runout

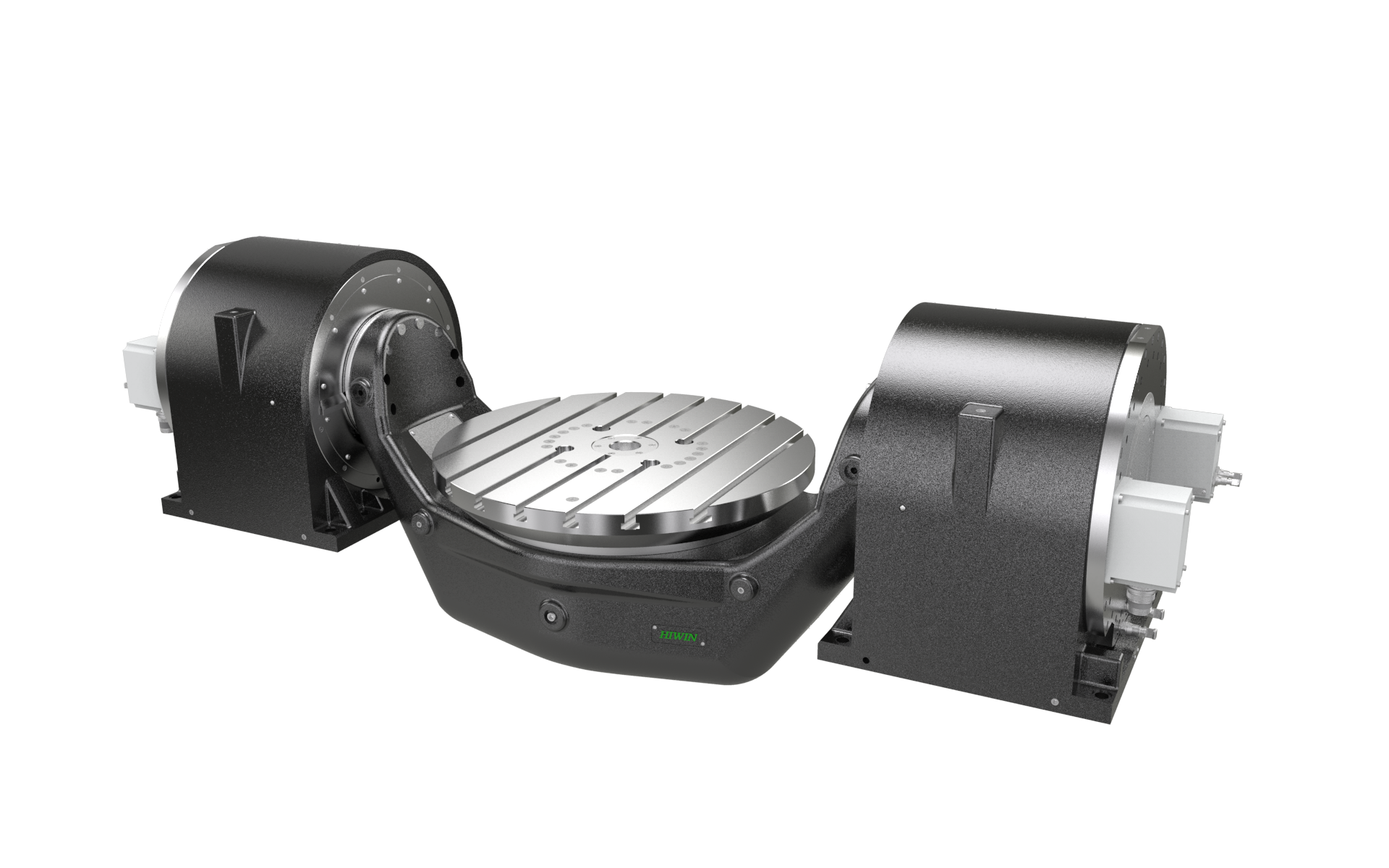

HIWIN TECHNOLOGIES CORPORATION

Product Description :

HIWIN Torque Motor Rotary table equips with HIWIN’s water cooled direct drive motor. With features of high torque, high precision and zero backlash including crossed roller bearings and pneumatic braking system, which plays an important role in the multi-axis machines. These rotary tables can increase the competitiveness of the machines with high speed, high performance, high precision and one time machining program reducing the errors during disassembly and clamping of components between multiple machines to complete the machining task, achieve the ability for complicate curve machining in one setup.

① The underwater rotary table (RCV-E series), lightweight insulation, up to IP 68 -rated waterproof and dustproof, suitable for discharge rotary cutting and grinding processing applications.

② Double axis rotary table (RAB/RAS Series)

Key component for high end multi axis machining center.

③ Single axis rotary table (RCV/RCH Series)

Widely used in turn-mill machining centers with speed up to 2,000 RPM.

ASMITH MANUFACTURING COMPANY

Product Description :

Spring Loaded Draw Latch |The proposed load of 22~50 kgf.

Both sides spring design with compression function.

Standard Lock-hole can using with lock. Suitable for vibration equipment.

Smooth surface, excellent brushed finish appearance, in accordance with RoHS.

The draw latch is including the horizontal keeper [CS(T)-0120-2 or CS(T)0130-2], if you need another type keeper then you can reference the below "Accessories".

➤Material: SUS304(Stainless steel)-vibration ground and brushed finish, SPCC(cold-rolled steel)-zinc plated

YOKE INDUSTRIAL CORP

Product Description :

1. 360° rotation and 230°pivot

2.Rotatable under load due to its unique ball bearing design.

3.Manufactured in accordance with EN1677‐1 and the requirements of ASME B30.26

4.Certified by DGUV GS‐OA‐15‐04

5. Forged alloy steel, quenched and tempered

6.With the Grade 100 High‐strength alloy steel, WLL is increased without increasing swivel size compared to other Yellow Point models.

7.4:1 Design factor

8.100% Magnaflux crack detected

9.Proof load at 2.5 times the WLL

10.Fatigue rated for 20,000 cycles at 1.5 times the WLL

MONGTEC PRECISION INC.

Product Description :

◎ The general spindle speed is only 6000-15000rpm, and the tool can be pushed up to 55000rpm through 15-70bar coolant pressure, saving 70% of cycle time

◎ Various interfaces can choose BT/HSK/ER/PCS/straight

◎ Tool can be changed by ATC

◎ Display processing tool speed with chip transmission

◎ Excellent run out within 0.003mm

GREEN ECO PRO CO. LTD.

Product Description :

Precision filtration system

Due to different grinding and processing materials, the particle size, quality, and hardness of the materials to be filtered will also vary. For this reason, our filtering equipment was designed, which can be used for quartz, silicon carbide, semiconductor grinding, electrical discharge machining, or high precision requirements and can effectively intercept fine impurities.

Continuous/batch processing

Customized tungsten steel stirring motor

Filter material saturation alarm

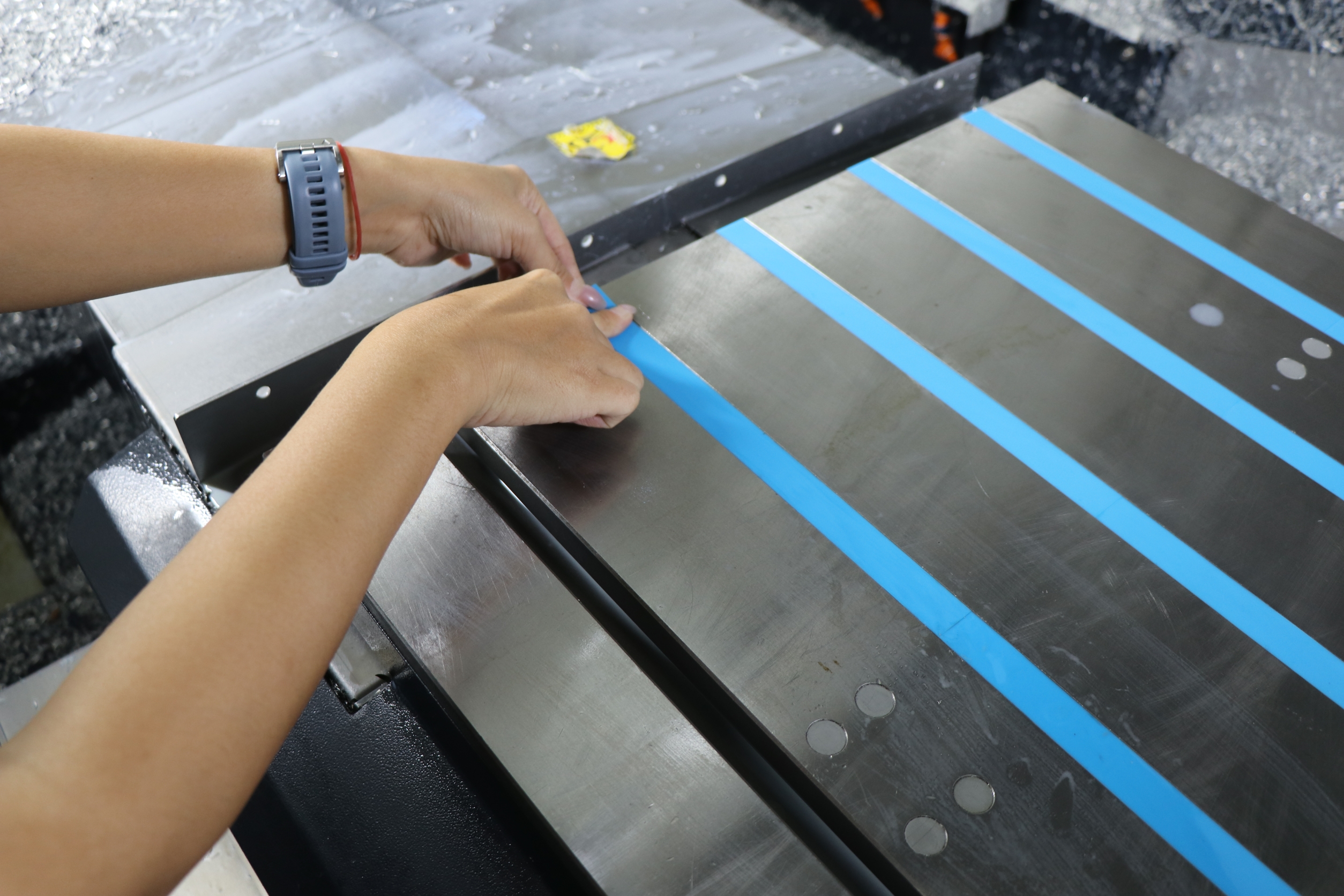

GREEN ECO PRO CO. LTD.

Product Description :

T- slot

The T-slot chip guard is developed to reduce your maintenance time cleaning your machine and changing your work-holding devices. They prevent chips and swarf from filling the T-grooves, which has always been a problem. It is not easy to wash away trapped chips with a coolant wash-down the gun or an air gun. The material is high-temperature resistant, flexible, and washable. In addition, it is extremely durable for dry machining applications. Overall, they look great and the kit is very affordable/cost-effective.

YINSH PRECISION INDUSTRIAL CO., LTD.

Product Description :

YINSH PRECISION IND . CO ., LTD . specializes in the production of superfine balanced locknuts for high speed machine tool spindles. SBL series is designed for all configurations of internal and direct drive spindles. Inner threads, outer skirts, clamping and trailing rims are all precision ground. Coupled with balanced adjustment screws, these locknuts stay perfectly balanced at high speeds. Made of high grade SCM440 alloy steel and hardened to HRC 48°-52°, rigidity and precision at high speeds is given. All locknuts can be fitted with adjustment screw hole screw-in plugs(option), eliminating high frequency noise and subsequent vibration.

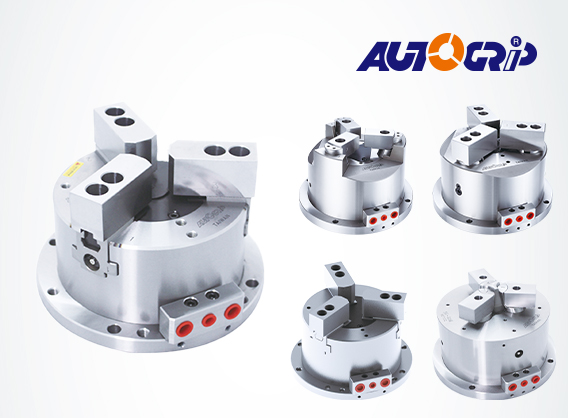

AUTOGRIP MACHINERY CO., LTD.

Product Description :

For stationary chuck, there are pull back, pull lock, thru-hole/non-thru-hole stationary chucks in the category.Multi-plate.4-plate(MP4)=>

For milling machine / machine center.

Allow simultaneous machining with up to 4 grippers.

(Order can be customized for 2,3,6 grippers).

Work with SP/SD/SU/SE vertical chuck.

Driven by Hydraulic or Pneumatic.

Individual circuit for each chuck.

Special design and reduce the height of working surface.

Lock valve unit (option).

Air tight detection function(option).