Theme

Digital Transformation

Green Transformation

Otennlux Lighting Technology Co.,Ltd

Product Description :

Otennlux LED intelligent signal lights use IO-Link interface, flexible and versatile, and

diversified applications, providing reliable control solutions for Industry 4.0 intelligent

automation industry. Reduce wiring, increase data availability, remote configuration and

monitoring, simple equipment replacement and advanced diagnosis, improve process

efficiency and increase machine availability.

HAINBUCH GmbH

Product Description :

Ideal for today's high paced manufacturing environment!

Convenient, that the HAINBUCH quick change-over systems fit on all your machines. Even better, that you can change your clamping devices in a matter of minutes, thus earning money quicker and allowing you to manufacture job-oriented. And, thanks to our unique technology, you will achieve a repeatability of ≤ 0.003 mm on the interface.

However, our high-speed solutions have even more to offer: As you will experience shorter machine downtimes along with reduced processing and throughput times,

your quick change-over systems will pay off in no time. Better yet, you will not have to compromise on quality, rigidity or precision.

Select the spindle connection and the clamping device that is right for you from our extensive assortment. We can even accommodate you if you are already using clamping devices made by other manufacturers. We will simply adapt them to our interface.

GREEN ECO PRO CO. LTD.

Product Description :

Precision filtration system

Due to different grinding and processing materials, the particle size, quality, and hardness of the materials to be filtered will also vary. For this reason, our filtering equipment was designed, which can be used for quartz, silicon carbide, semiconductor grinding, electrical discharge machining, or high precision requirements and can effectively intercept fine impurities.

Continuous/batch processing

Customized tungsten steel stirring motor

Filter material saturation alarm

YINSH PRECISION INDUSTRIAL CO., LTD.

Product Description :

YINSH PRECISION IND . CO ., LTD . specializes in the production of superfine balanced locknuts for high speed machine tool spindles. SBL series is designed for all configurations of internal and direct drive spindles. Inner threads, outer skirts, clamping and trailing rims are all precision ground. Coupled with balanced adjustment screws, these locknuts stay perfectly balanced at high speeds. Made of high grade SCM440 alloy steel and hardened to HRC 48°-52°, rigidity and precision at high speeds is given. All locknuts can be fitted with adjustment screw hole screw-in plugs(option), eliminating high frequency noise and subsequent vibration.

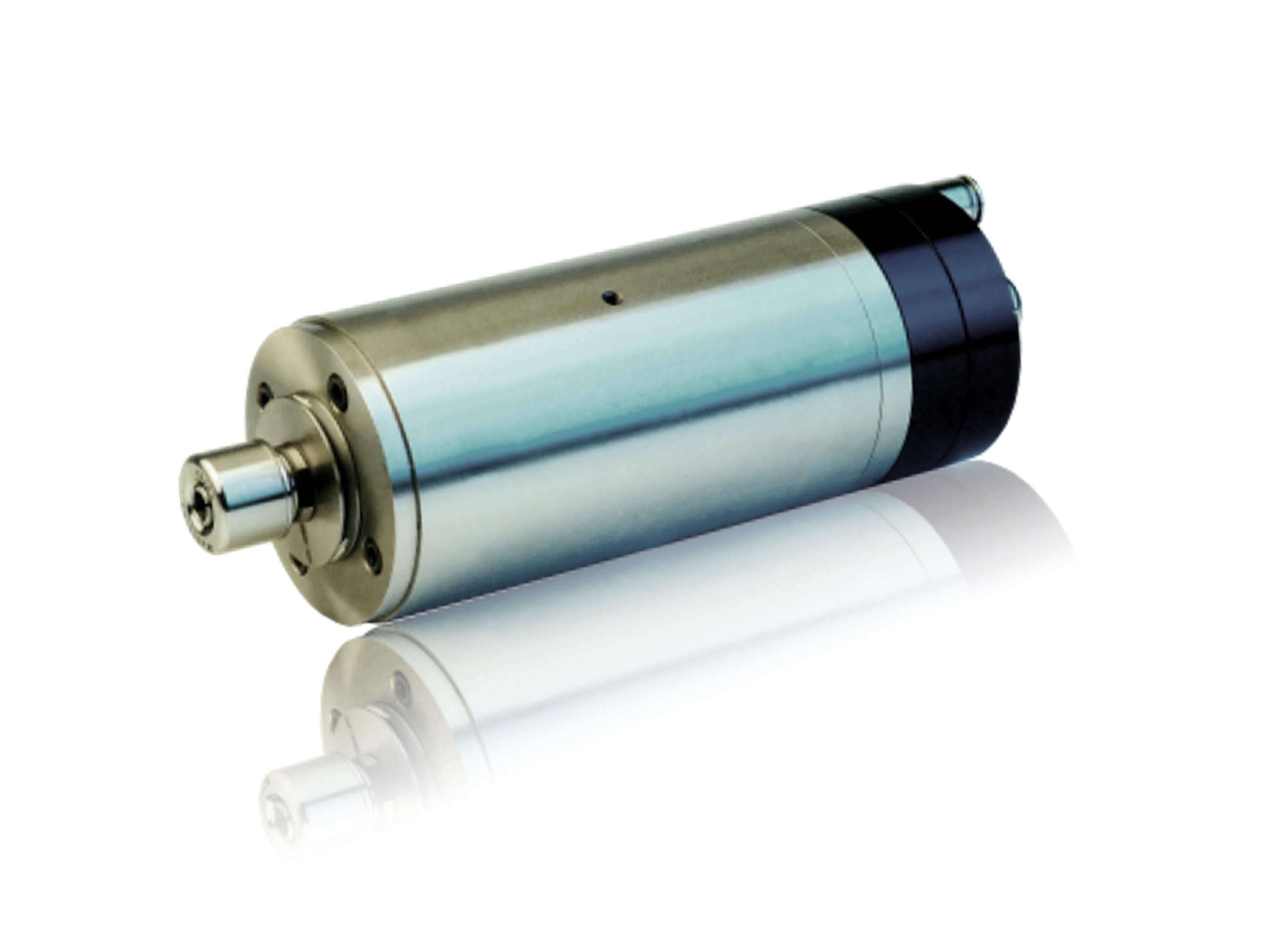

MONGTEC PRECISION INC.

Product Description :

◎ The general spindle speed is only 6000-15000rpm, and the tool can be pushed up to 55000rpm through 15-70bar coolant pressure, saving 70% of cycle time

◎ Various interfaces can choose BT/HSK/ER/PCS/straight

◎ Tool can be changed by ATC

◎ Display processing tool speed with chip transmission

◎ Excellent run out within 0.003mm

YIH KUAN ENT CO., LTD.

Product Description :

The Plano Milling Head (Gantry Milling Head) are commonly used milling machine heads such as gantry milling machines, boring milling machines, and double-head milling machines. Uses include rough milling, finishing milling, boring holes... and other processing requirements.

The left and right vertical milling heads offer excellent flexibility and adaptability. Their adjustable angles and swivel capabilities enable operators to perform angular milling, drilling, and other complex operations with ease. They are compatible with different milling machines, providing a seamless integration into existing setups or as a valuable addition to new milling machine installations.

1. IK milling heads can upgrade or replacement your existing machine body, milling machine or special machine and also it can bring more stable and high-quality machining benefits for work piece cutting.

2. It is used for mold manufacturing or precision processing.

3. The machine processing for travel is 320 mm. We also provide “No slide” format.

4. This product is used in Gantry (Plano) Milling Machine (vertical / horizontal), suitable for heavy metal cutting.

5. Plano milling head series offer accessory head for you to optional.

It will apply for multi-angle machining to upgrade efficiency and longer machining range.

6. This product of standard motor is 10HP. We also offer 12.5HP for you to optional.

7. Offer pneumatic blade locking device, bearing guide screw, pneumatic leveler for you to optional.

8. There are 10 models in IK Plano Milling Machine Head Series.